Full-automatic electromagnetic element production line with adhesive dispensing system

An electromagnetic component, fully automatic technology, applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as inability to work continuously, insufficient dispensing area, high manufacturing cost, etc., to improve work efficiency and reduce manpower Quantity, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

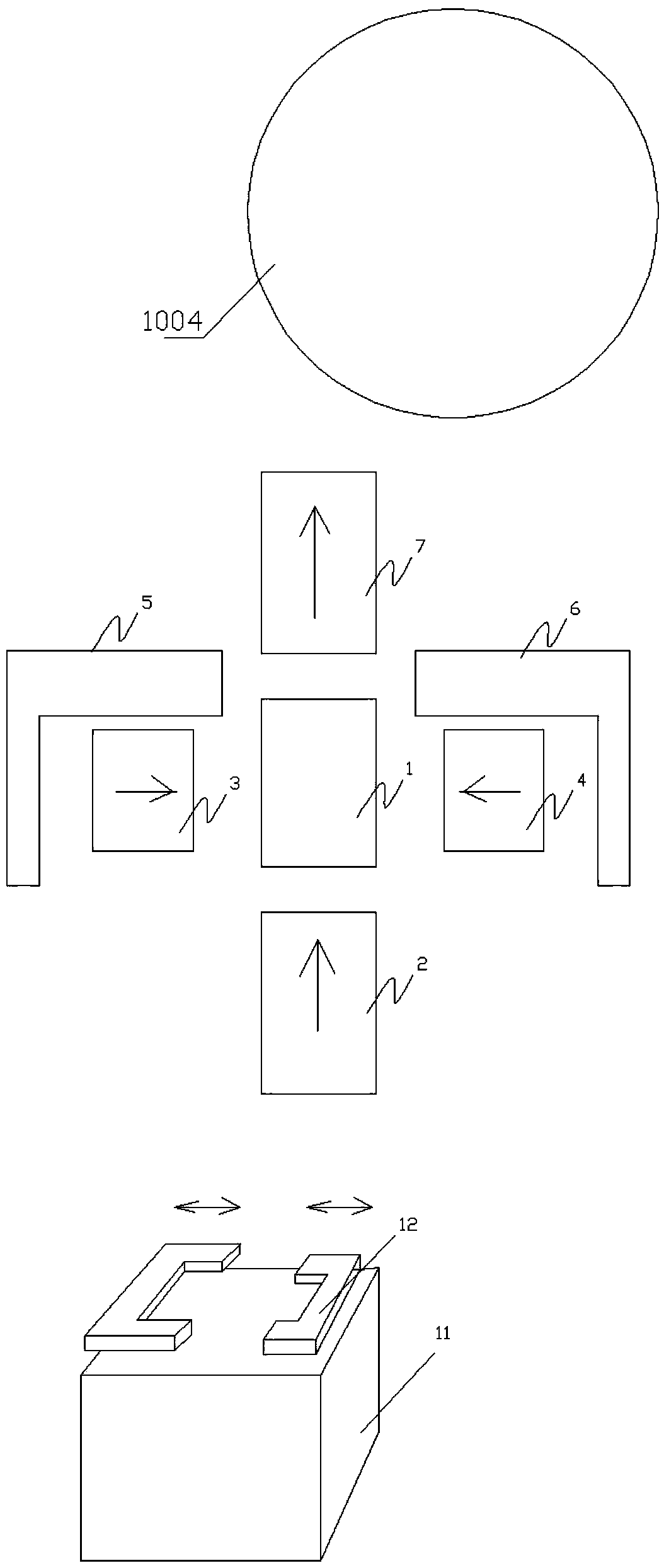

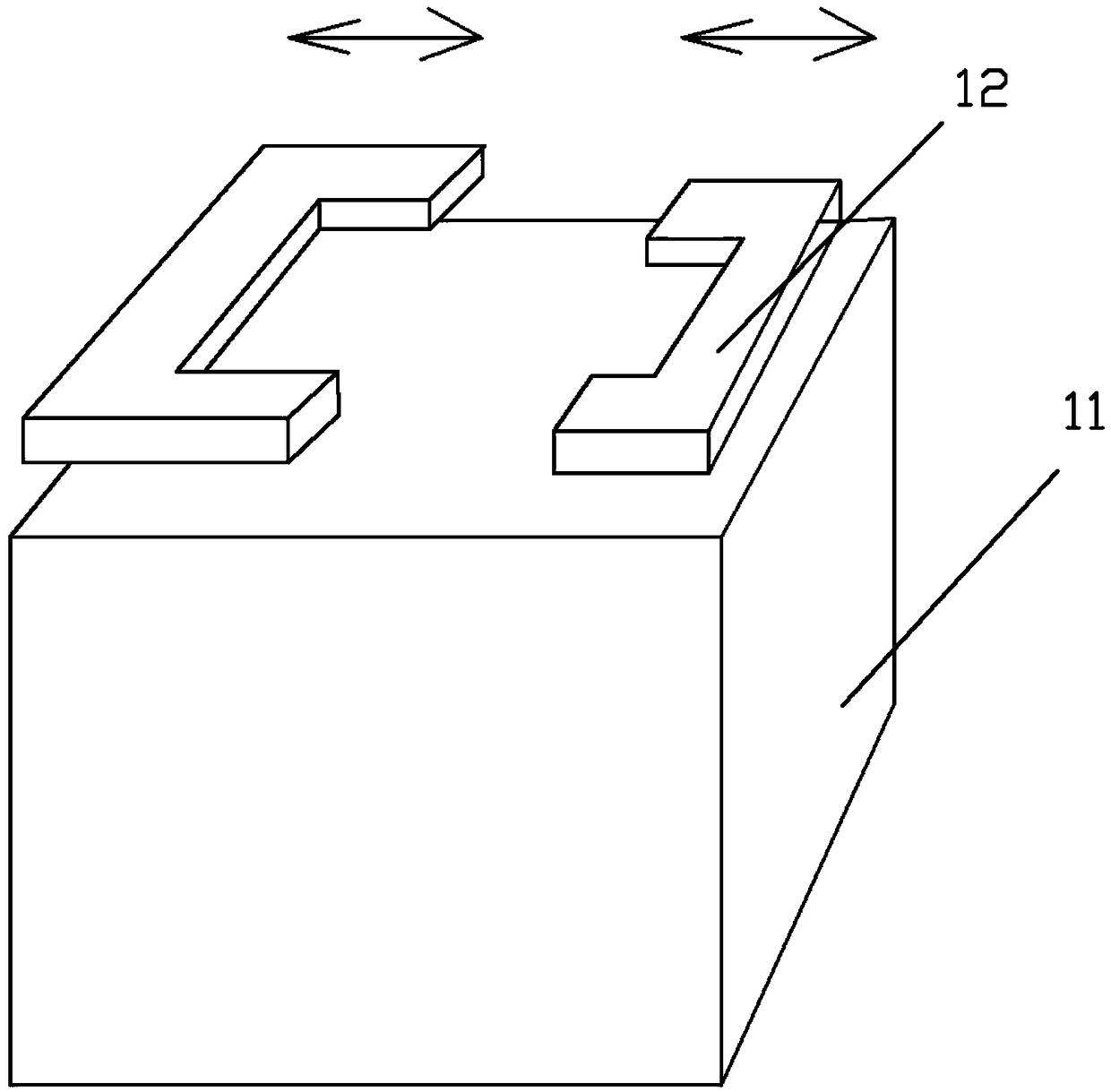

[0041] Such as Figure 1 to Figure 8 It includes:

[0042] Workpiece assembly device 1;

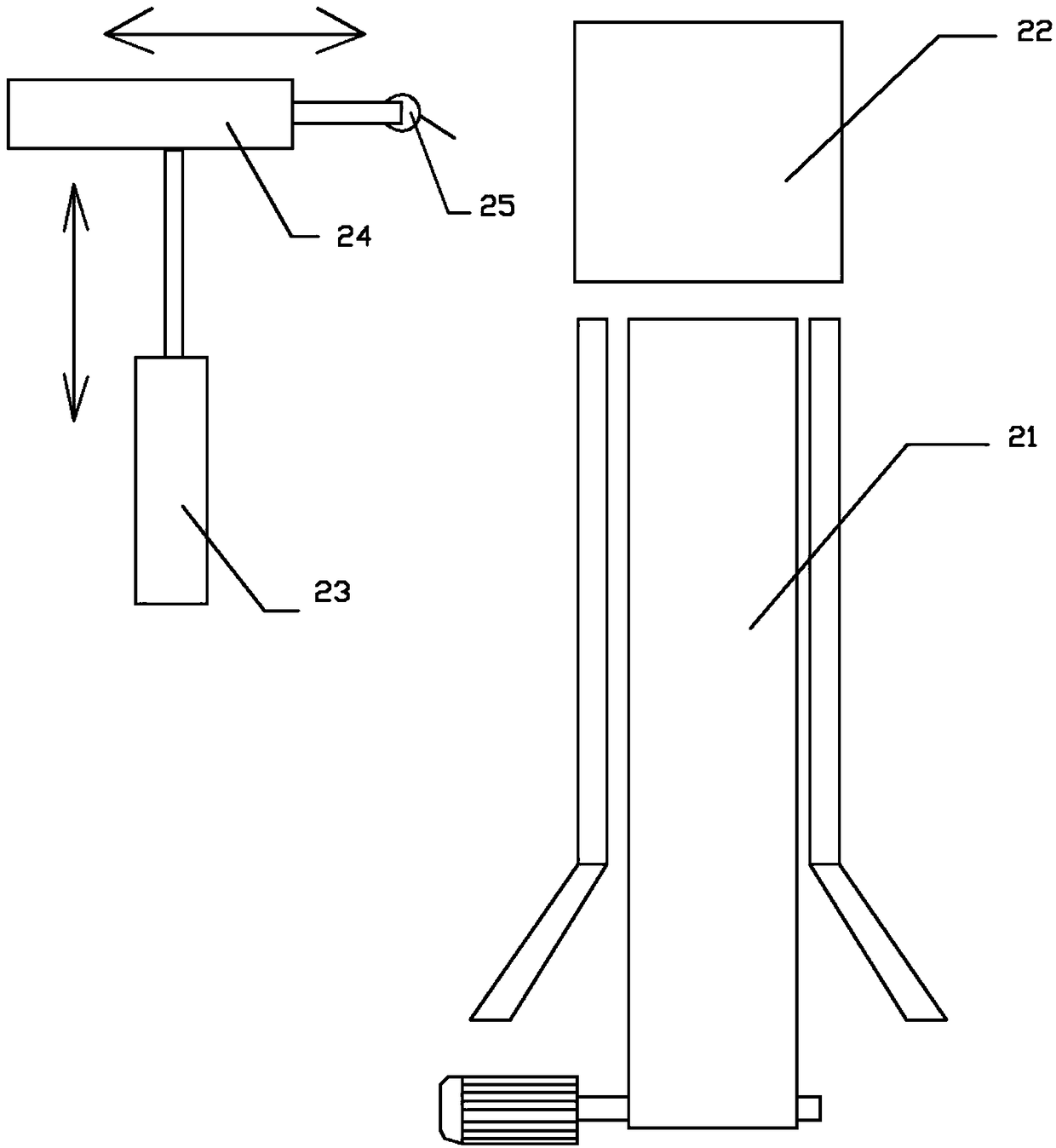

[0043] Skeleton feeding device 2, which is provided with the front end of workpiece assembly device 1;

[0044] The first magnetic core feeding device 5 is located at the left end of the workpiece assembly device 1;

[0045] The second magnetic core feeding device 6 is located at the right side end of the workpiece assembly device 1;

[0046] Feeding manipulator 7, above its workpiece assembly device 1;

[0047] Turntable device 1004, which and the workpiece assembly device 1 are respectively located below the two ends of the feeding manipulator 7;

[0048] Grinding device 1001, which is located between the workpiece assembly device 1 and the turntable device 1004;

[0049] Correction device 1002, which is located between the grinding device 1001 and the turntable device 1004;

[0050] Several pressure maintaining devices 2000, which are located on the turntable device 1004;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com