Production method of carbon fiber filaments

A production method and technology of carbon fiber filaments, applied in the field of carbon fiber material manufacturing, can solve the problems of unfavorable carbon fiber manufacturing cost, relatively high energy consumption, high pre-oxidation temperature and low-temperature carbonization, and achieve good compactness, carbon fiber strength, and fiber orientation Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

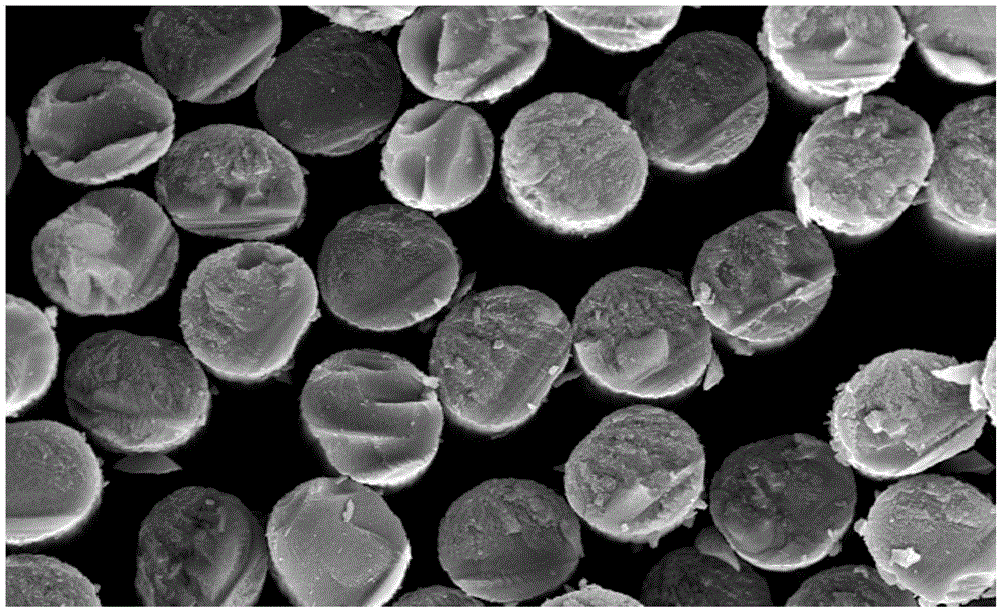

Image

Examples

Embodiment 1

[0021] The production method of present embodiment carbon fiber silk comprises the following steps:

[0022] Step 1, pre-oxidation:

[0023] Select good-quality and defect-free polyacrylonitrile-based carbon fiber precursors, and then spray the carbon fiber precursors with deionized water to humidify and dry them according to conventional methods, and then send them into a pre-oxidation furnace for pre-oxidation treatment. The pre-oxidation treatment adopts a four-temperature zone pre-oxidation treatment process, which can be completed by one or multiple pre-oxidation furnaces connected in series. The pre-oxidation in each temperature zone uses air as the medium, and the temperature of the pre-oxidation treatment in each temperature zone Under the conditions of 180°C, 231°C, 251°C and 262°C respectively, the carbon fiber precursors are subjected to gradient pre-oxidation treatment; the transmission of carbon fiber precursors is realized by transmission rollers between the four...

Embodiment 2

[0037] The production method of present embodiment carbon fiber silk comprises the following steps:

[0038] Step 1, pre-oxidation:

[0039] Select good-quality and defect-free polyacrylonitrile-based carbon fiber precursors, and then spray the carbon fiber precursors with deionized water to humidify and dry them according to conventional methods, and then send them into a pre-oxidation furnace for pre-oxidation treatment. The pre-oxidation treatment adopts a four-temperature zone pre-oxidation treatment process, which can be completed by one or multiple pre-oxidation furnaces connected in series. The pre-oxidation in each temperature zone uses air as the medium, and the temperature in each temperature zone is 180 ° C. Under the conditions of , 231°C, 251°C and 262°C, the carbon fiber precursors are subjected to gradient pre-oxidation treatment; the transmission of carbon fiber precursors is realized through transmission rollers between the four temperature zones. During the ...

Embodiment 3

[0053] The production method of present embodiment carbon fiber silk comprises the following steps:

[0054] Step 1, pre-oxidation:

[0055] Select good-quality and defect-free polyacrylonitrile-based carbon fiber precursors, and then spray the carbon fiber precursors with deionized water to humidify and dry them according to conventional methods, and then send them into a pre-oxidation furnace for pre-oxidation treatment. The pre-oxidation treatment adopts a four-temperature zone pre-oxidation treatment process, which can be completed by one or multiple pre-oxidation furnaces connected in series. The pre-oxidation in each temperature zone uses air as the medium, and the temperature in each temperature zone is 180 ° C. Under the conditions of , 231°C, 251°C and 262°C, the carbon fiber precursors are subjected to gradient pre-oxidation treatment; the transmission of carbon fiber precursors is realized through transmission rollers between the four temperature zones. During the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com