Communication pole tower with steel tube pile as foundation

A technology of communication poles and steel pipe piles is applied in the field of communication towers, which can solve the problems of long construction period, complicated process and lack, and achieve the effects of short construction period, convenient disassembly and assembly, and guaranteed structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

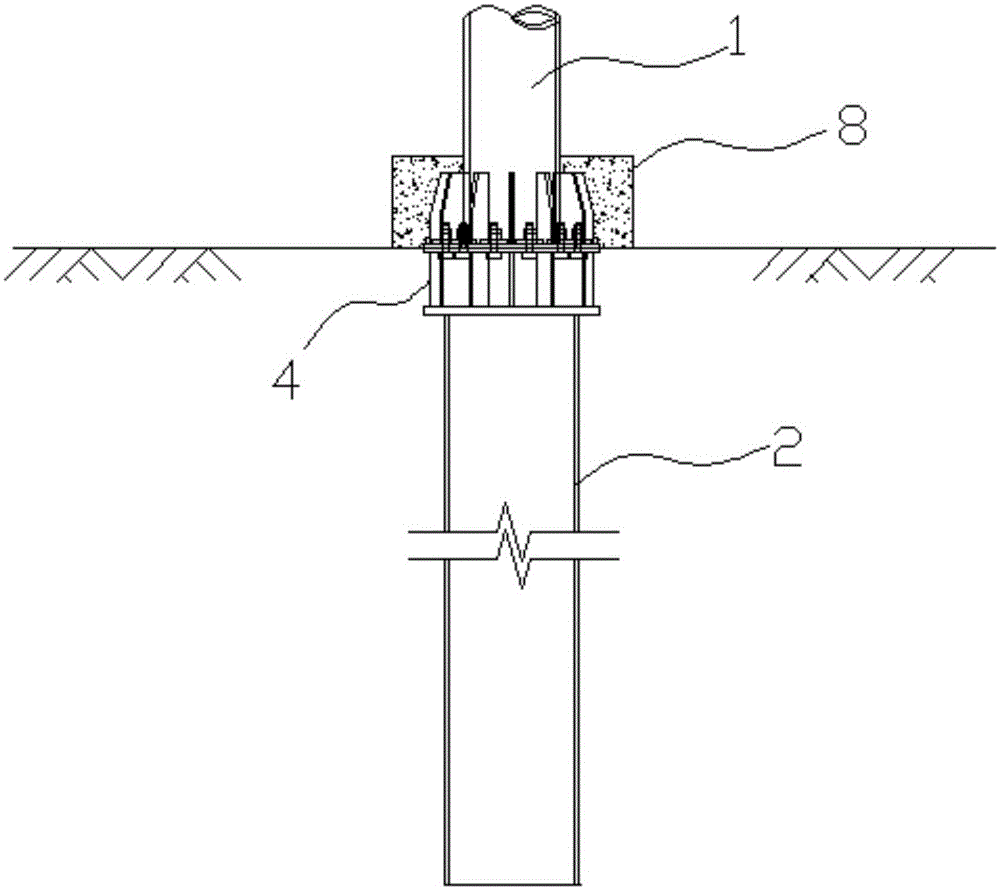

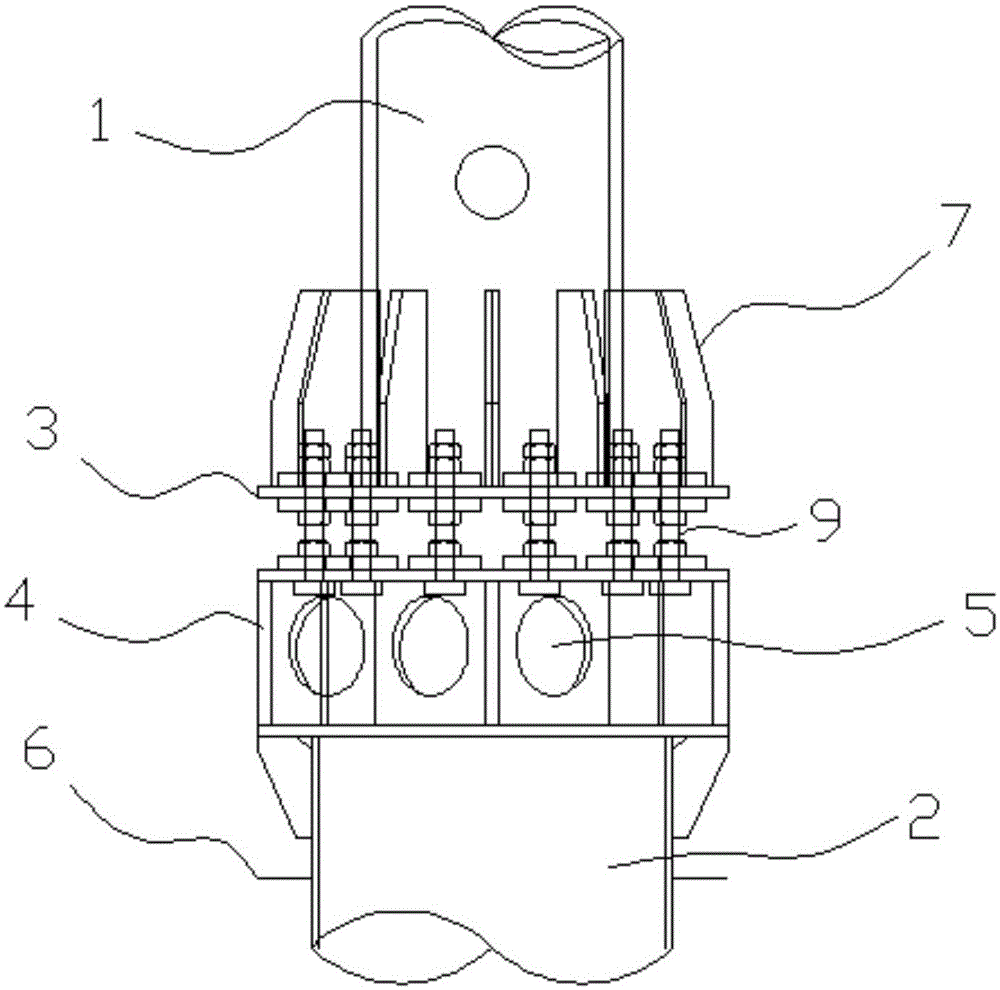

[0025] Embodiment 1: as figure 1 , figure 2In the shown embodiment, a steel pipe pile foundation communication pole tower includes a tower body 1, a steel pile 2 for extending into the ground, the bottom of the tower body is provided with a tower bottom flange 3, and the top of the steel pile A pile top flange 4 is provided, and the tower bottom flange and the pile top flange are connected through connecting pieces, and the pile top flange is provided with a number of lower routing reservations for cables to pass through. hole 5, the outer wall of the steel pile is provided with a number of reserved grounding ends 6, the pile top flange is provided with a number of strengthening connecting pieces 7, and the outer bottom of the tower body is provided with a concrete encased tower foot 8 , the pile top flange and the reinforcing connecting piece are all located in the concrete-encapsulated tower foot and connected with the concrete-enclosed tower foot. Steel piles do not need...

Embodiment 2

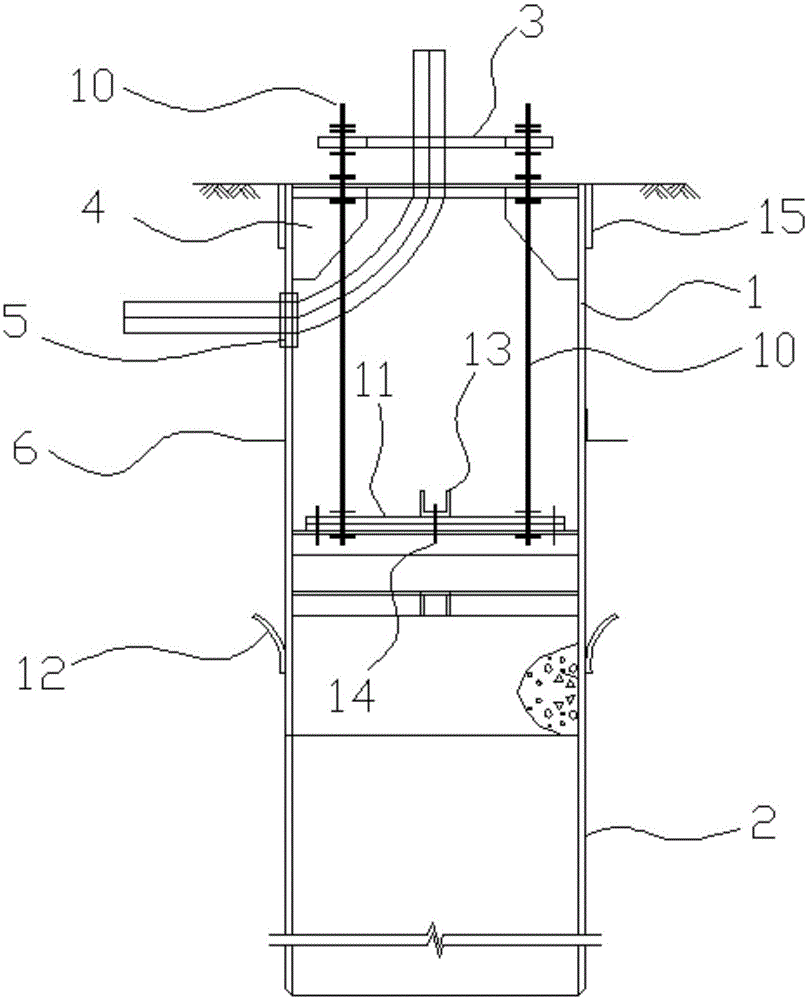

[0027] Embodiment 2: as image 3 , Figure 4 In the shown embodiment, a steel pipe pile foundation communication pole tower includes a tower body and steel piles for extending into the ground, the bottom of the tower body is provided with a tower bottom flange, and the top of the steel pile is provided with a pile The top flange, the tower bottom flange and the pile top flange are connected through a connecting piece, and the pile top flange is provided with a number of reserved holes for cables to pass through. The outer wall of the steel pile is provided with a number of reserved grounding ends, the pile top flange is provided with a number of reinforced connecting pieces, the outer bottom of the tower body is provided with a concrete-encased tower foot, and the pile top flange and the reinforcing connecting piece are all located in the concrete-encapsulated tower foot and connected with the concrete-enclosed tower foot. Steel piles do not need to be poured into shape, and...

Embodiment 3

[0032] Embodiment 3: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 5 , Image 6 , Figure 7 As shown in , it also includes a trigger cylinder 16 and a pullback protection cylinder 17. The trigger cylinder is fixedly connected to the ground, the top wall of the trigger cylinder is provided with a threading hole 18, and the tower body is provided with There is a trigger cable 19, and the trigger cylinder is provided with a trigger piston 20 slidingly connected to the trigger cylinder, and the sliding direction is the up and down direction. One end of the trigger cable is connected to the tower body, and the other end is connected to the trigger piston. Through the threading hole, the trigger piston is at the bottom of the trigger cylinder, and at least one limit spring 21 is arranged in the trigger cylinder, the upper end of the limit spring is connected to the top wall of the trigger cylinder, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com