Negative pressure drainage system and drainage method

A drainage system and negative pressure technology, applied in waterway systems, sewage removal, water supply devices, etc., can solve the problems of less application of negative pressure drainage system and no systematic research, etc., to facilitate daily maintenance and management, improve operation stability, Good sewage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the invention will be further described in detail below.

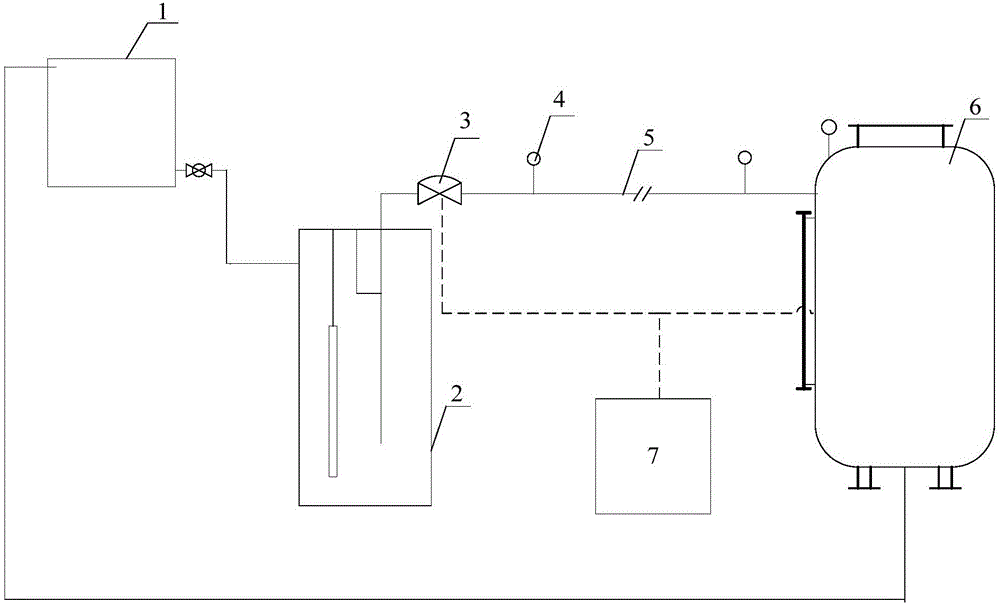

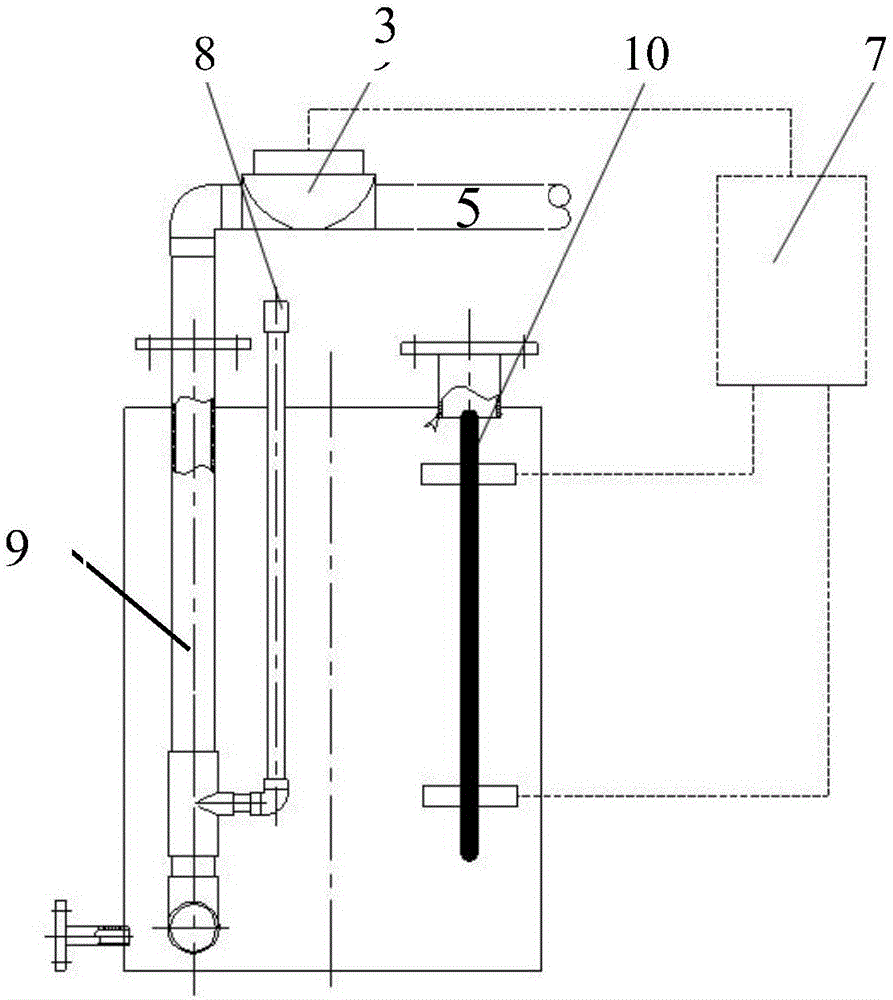

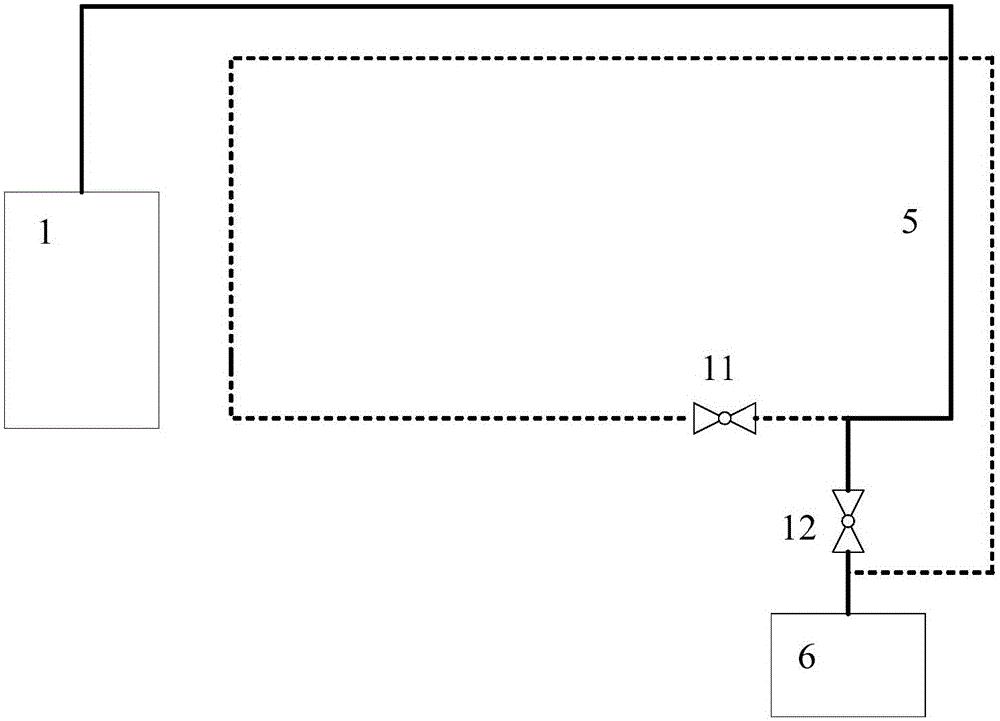

[0024] Such as Figures 1 to 5 As shown, the negative pressure drainage system of an embodiment includes: a control unit 7, a circulating water tank 1, a vacuum valve well 2, a first valve 3, an air intake pipe 8, a suction pipe 9, a liquid level detector 10, a vacuum pipe 5 and a vacuum pump Station 6. Vacuum pump station 6 comprises barometer 4, vacuum tank 16, vacuum pump 17, sewage pump 23 and liquid level detector 24, and vacuum pump 17 can adopt water ring vacuum pump (comprising vacuumizing water tank 18).

[0025] The water outlet of the circulating water tank 1 is connected to the water inlet of the vacuum valve well 2, the first end of the suction pipe 9 stretches into the bottom of the vacuum valve well 2, and the second end of the suction pipe 9 is connected with the vacuum tank 16 through the vacuum pipeline 5, the first Valve 3 can adopt electric butterfly valve, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com