Front cover lock of car

A front cover lock and automobile technology, which is applied in the field of automobile parts, can solve problems such as user complaints, deformation of the handle 7, abnormal impact noise, etc., and achieve the effect of reducing user complaints, reducing space requirements, and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

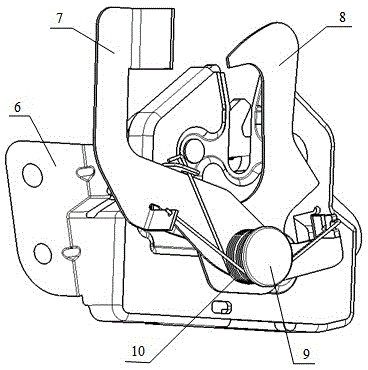

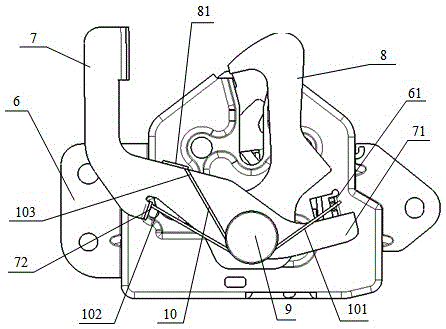

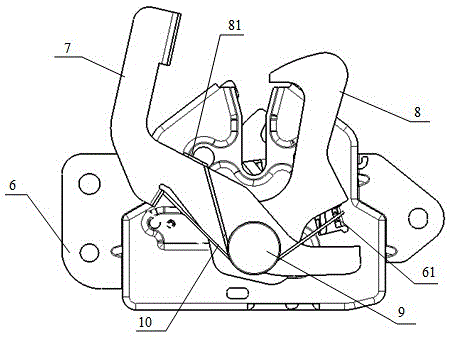

[0016] see figure 1 and figure 2 As shown, the automobile front cover lock comprises a front cover lock box 6, a handle 7, a lock hook 8, a bearing pin 9 and a torsion spring 10, and the pin shaft 9 is fixed on the front cover lock box 6, and on the front cover lock box 6 A lock box limit block 61 is provided, the handle 7 and the lock hook 8 are mutually independent components, and the middle parts of the handle 7 and the lock hook 8 are both sleeved on the rotating shaft 9 to rotate with the rotating shaft 9 . The lock box limiting block 61 is located between the top of the handle end 71 and the bottom of the middle part of the lock hook. A lock hook limiting block 81 is arranged at the end of the locking hook 8, and the locking hook limiting block 81 is located above the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com