A dual-coil radial spherical purely electromagnetic bearing

A magnetic bearing and dual-coil technology, applied in the non-contact support of magnetic levitation flywheel or magnetic levitation control torque gyroscope, and spherical pure electromagnetic magnetic bearing field, can solve the problem of increasing the torsional bearing load of the flywheel, uneven electromagnetic force, and affecting the uniformity of magnetic density. and other problems, to achieve the effect of eliminating the interference of radial translation, improving the current response rate, and improving the uniformity of the circumference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

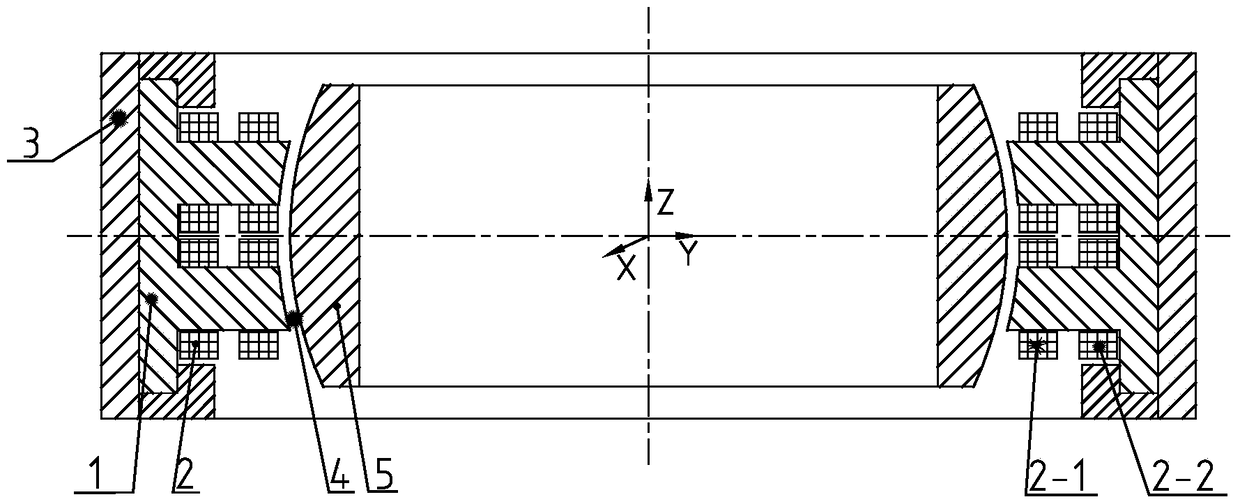

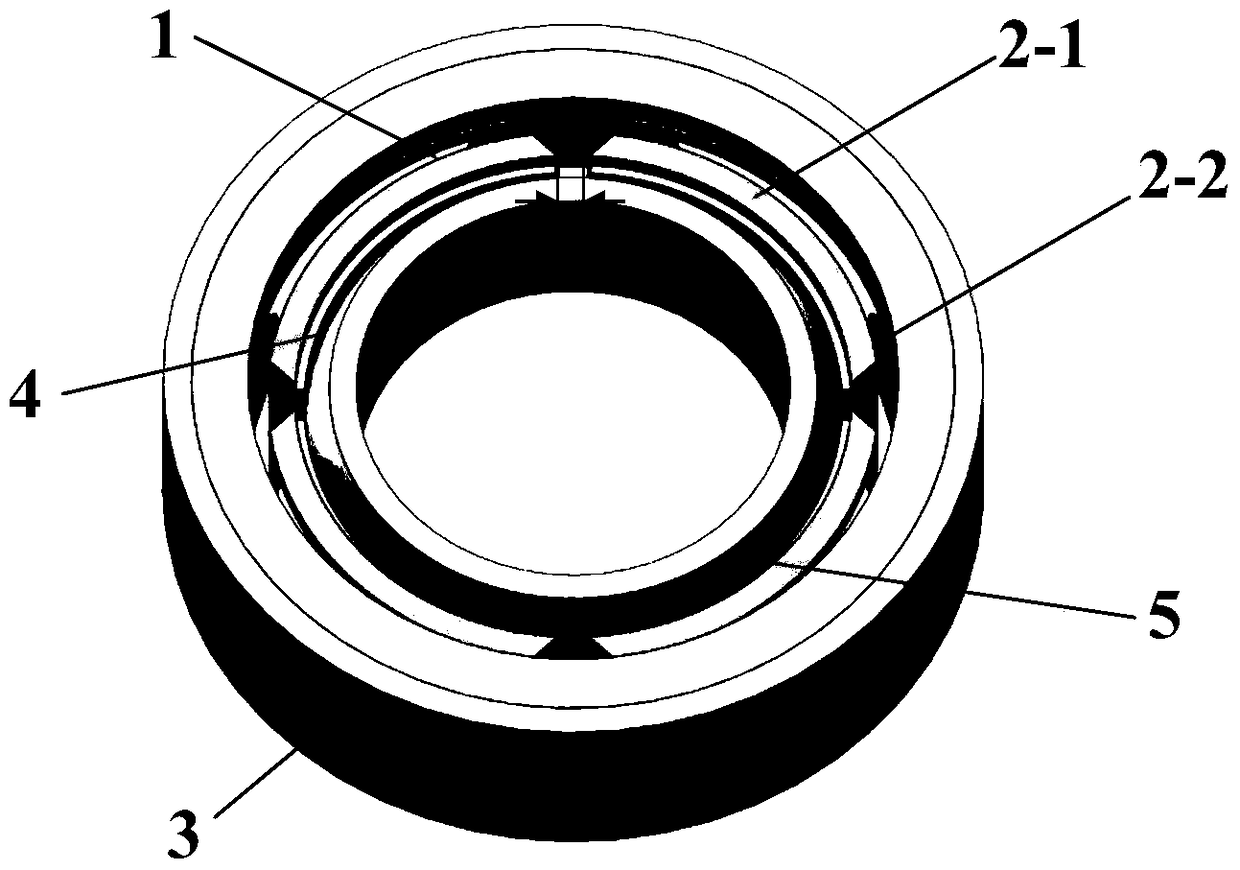

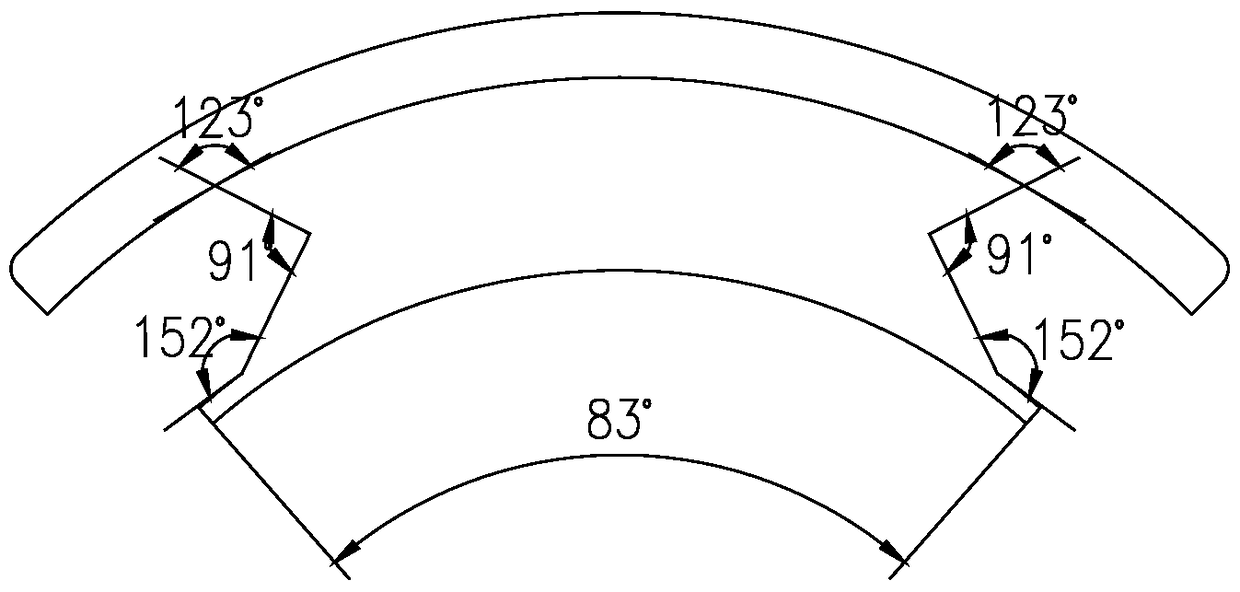

[0020] Such as figure 1 with figure 2 As shown, a double-coil radial spherical pure electromagnetic bearing mainly includes: four stator cores (1), coils (2), sleeves (3), air Gap (4) and rotor (5). The radial bearing coil (2) is wound on the two magnetic poles of each stator core (1), the radial inner side of the four stator cores (1) is the rotor (5), the stator core (1) and A radial magnetic air gap (4) is formed between the rotors (5), and the radially outer side of the stator core (1) is a sleeve (3). The magnetic poles of each stator core (1) are divided into front, In the middle part and the root part, the angle formed by the left edge and the right edge of the front part is 83°, and the distance between the magnetic poles of two adjacent stator cores (1) along the circumference is 2mm (such as figure 2 shown), the angle between the left edge of the front part of each stator core (1) and the junction of the middle part is 152°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com