Gas flow control valve for gas engine

A gas engine and gas flow technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of high manufacturing cost, discontinuous gas output, and small gas output flow, and achieve good market application value and gas utilization efficiency High, low overall cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and specific embodiments:

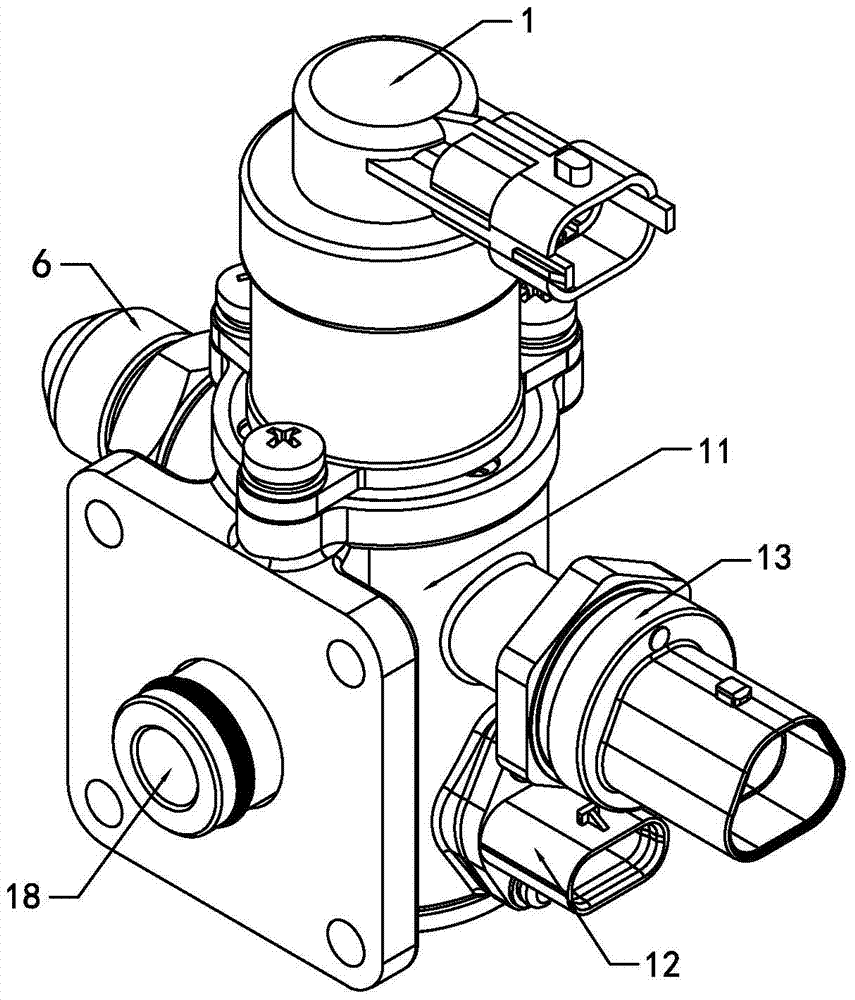

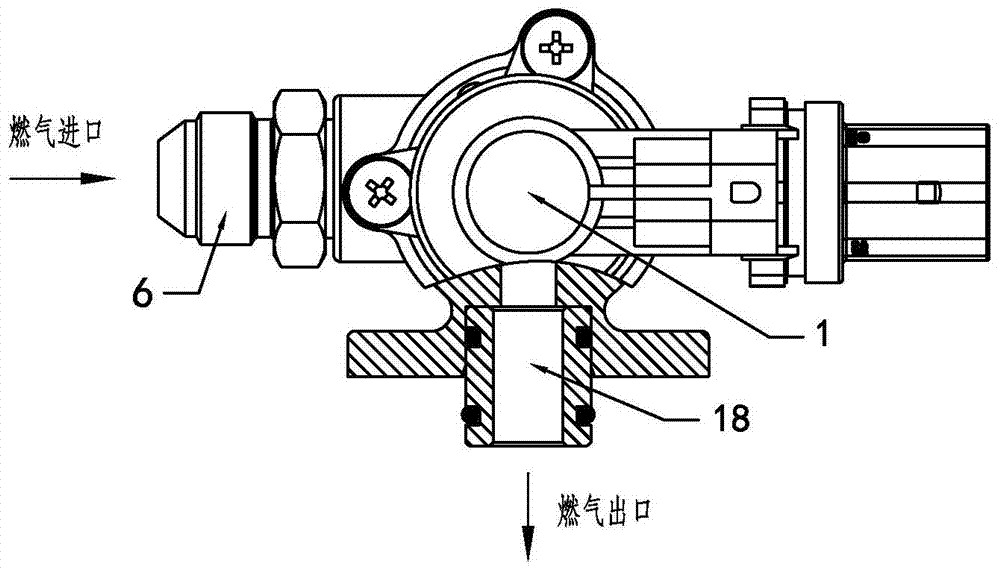

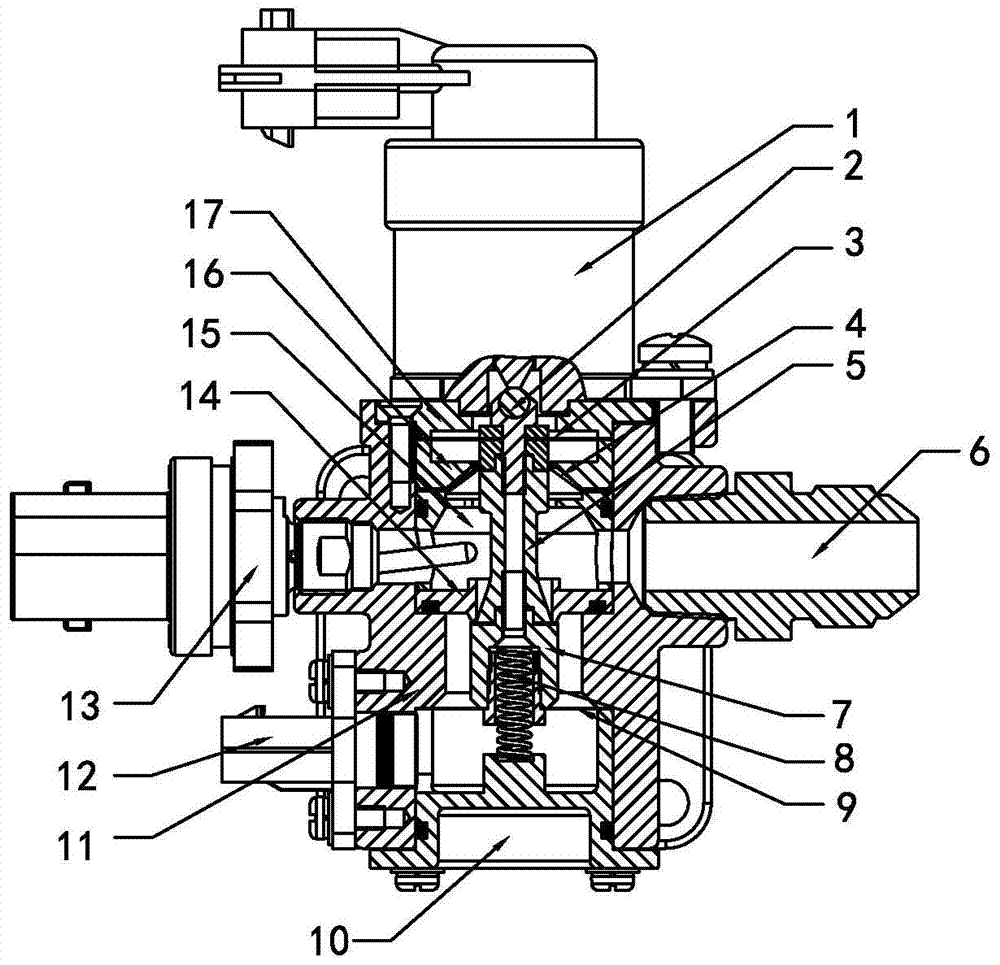

[0020] Such as Figure 1 to Figure 3 As shown, the gas flow control valve for a gas engine of the present invention includes a main body 11, the main body 11 is a cylinder penetrating up and down, the upper opening of the main body 11 is vertically installed with a driving source 1, and the lower end opening is provided with a lower cover 10 for sealing. There are gas inlets and gas outlets on the side walls. The gas inlet is located higher than the gas outlet, the gas inlet is provided with an air inlet connector 6, and the gas outlet is provided with a gas outlet connector 18; The valve 14 and the valve core are in airtight contact. The valve 14 has a circular ring shape. The valve 14 separates the space inside the main body 11 into an inlet chamber and an outlet chamber. The inlet chamber communicates with the gas inlet, and the outlet chamber communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com