Micromovement actuator used for adjusting mirror surface position of astronomical telescope

An astronomical telescope and micro-displacement technology, used in telescopes, instruments, optics, etc., can solve the problems of high price of inchworm motors, small displacement actuator strokes, complex mechanical mechanisms, etc., and achieve simple structure, high stroke, and high rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

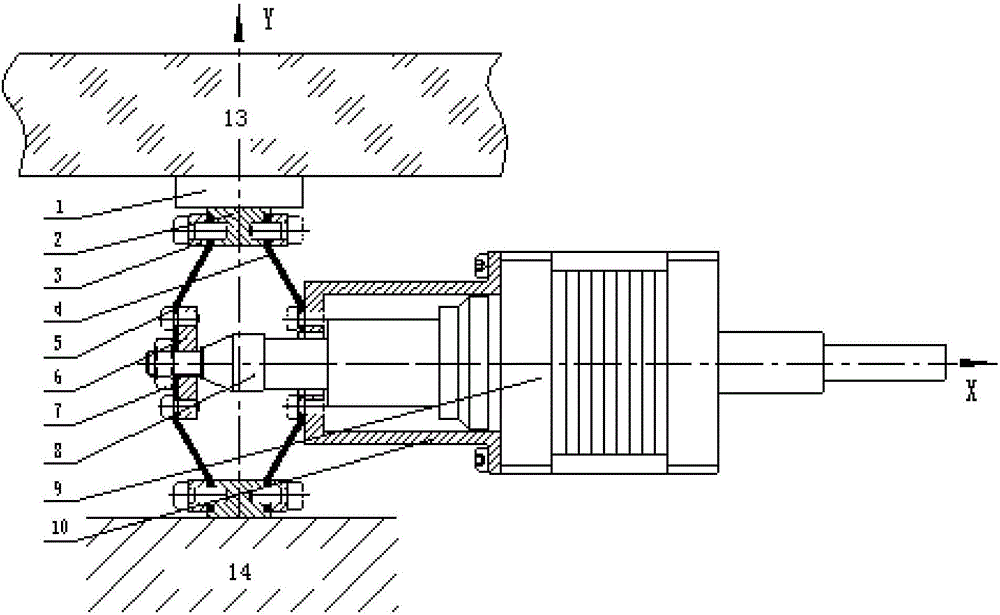

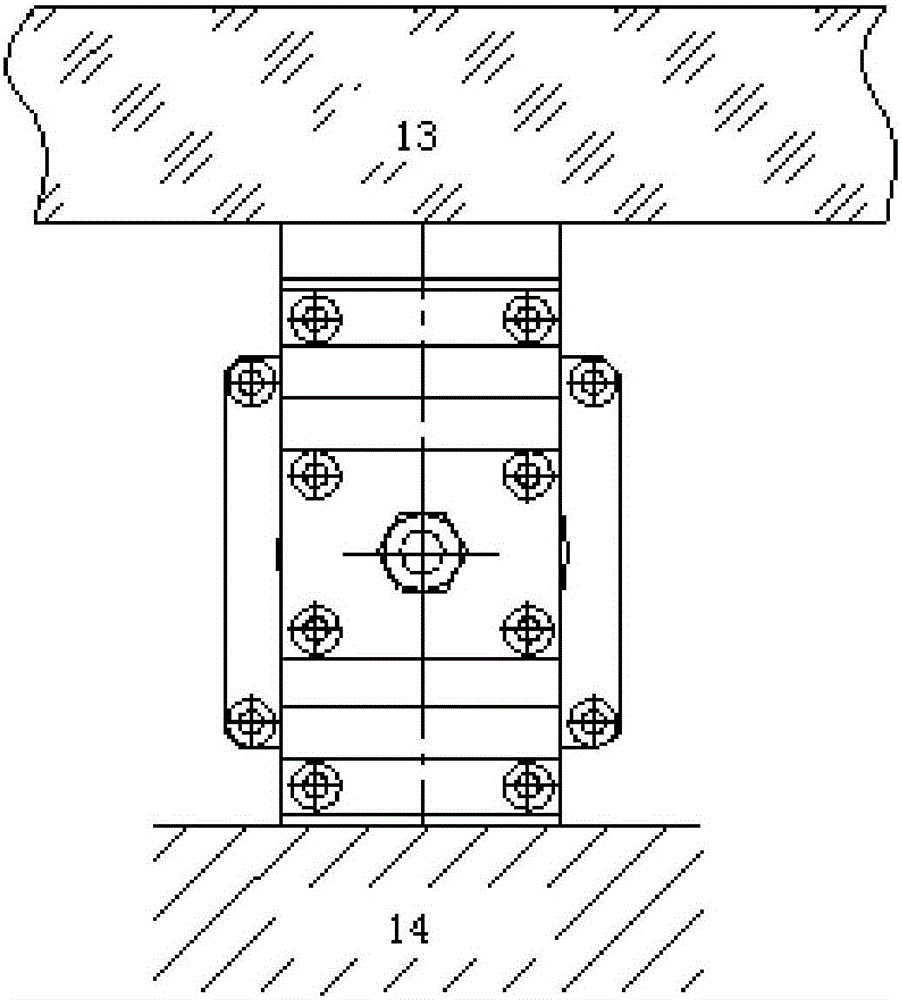

[0034]Embodiment 1, the working principle of the micro-displacement actuator Picture 1-1 , Figure 1-2 shown. Elastic piece I4, elastic piece II5 and two connecting seats 2 form an octagonal elastic structure, the upper end of the octagon is connected to the mirror surface 13 through the indium steel pad 1, the lower end is connected to the telescope frame 14, and the right end passes through a transition The connecting seat 10 is connected with the linear motor housing, and the left end of the octagonal elastic structure is connected with the output shaft 8 of the linear motor through a compression nut 7 and an anti-backlash pressing plate 6 (also called "liner"). During the working process of the micro-displacement actuator, the linear motor 9 is driven so that when the motor shaft 8 is stretched out, the interval between the two elastic pieces of the octagonal elastic structure in the X-axis direction becomes larger, that is, the left elastic Sheet I4 produces a negative ...

Embodiment 2

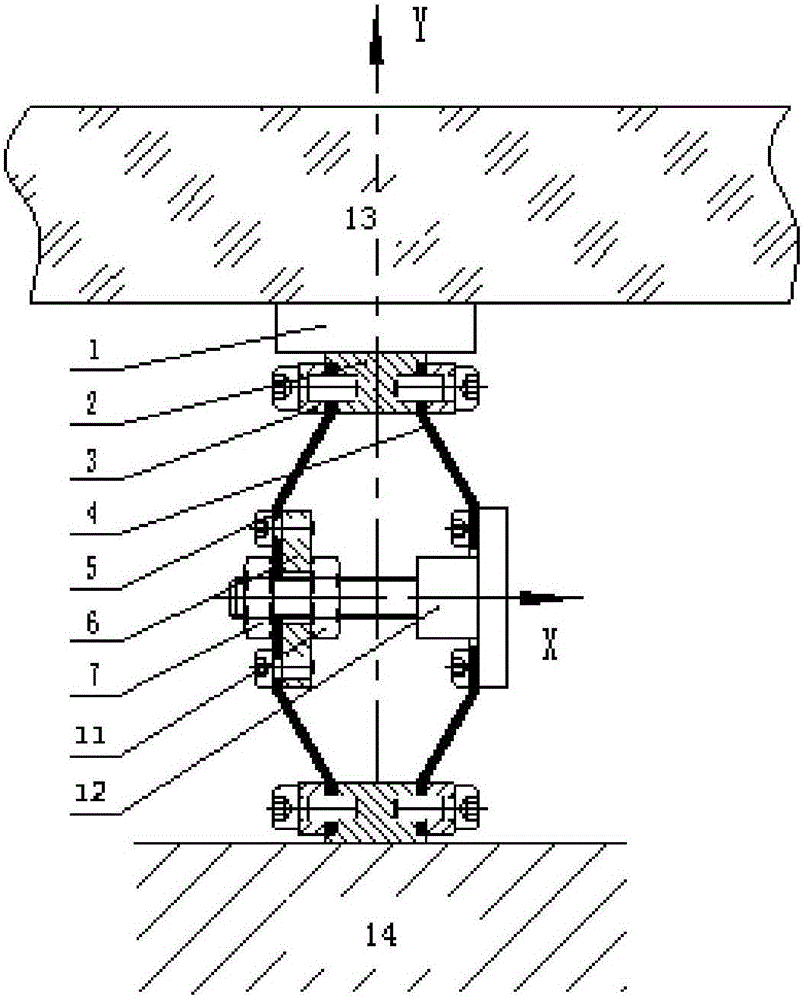

[0035] Embodiment 2, if the linear motor is replaced with a central shaft with a fine thread, the electric micro-displacement actuator becomes a manual micro-displacement adjustment mechanism. The schematic diagram of the micro-displacement adjustment mechanism is shown in diagram 2-1 , Figure 2-2 shown. During the working process, it is only necessary to manually adjust the compression nut I7 and the compression nut II11 to move along the negative direction of the X-axis at the same time, so that the mirror surface can move slightly along the negative direction of the Y-axis. Conversely, by manually adjusting the compression nut I7 and the compression nut II11 to move along the positive direction of the X-axis at the same time, the micro-displacement adjustment of the mirror surface along the positive direction of the Y-axis can be realized. 12 among the figure is the central axis with fine thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com