Method for installing drilling tool electronic tag

An electronic label and installation method technology, applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of destroying the integrity of the surface, damage, glue aging, etc., to ensure information transmission, installation procedures are simple, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further disclose the technical solution of the present invention, the following will be described in detail in conjunction with the accompanying drawings in the description:

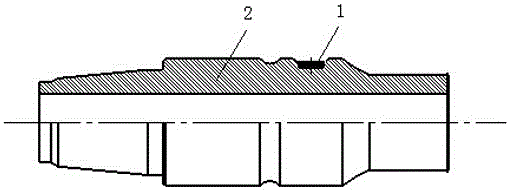

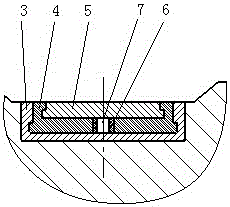

[0017] The invention relates to a method for installing an electronic tag for a drilling tool, which is characterized in that: the electronic tag for a drilling tool 1 is installed on a drill tool joint; a circular groove is drilled on the cylindrical surface of the drill tool joint 2, and the circular groove A label base 3 is installed on the outer periphery, a layer of thermal insulation material 4 is installed on the inner circumference of the label base, a cylindrical antenna 5 is installed on the inner circumference of the thermal insulation material, and a circular hole is drilled at the center of the bottom of the insulating material. An electronic label chip 7 is installed in the round hole, and a layer of sealant 6 is filled on the periphery of the drilling tool electronic labe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com