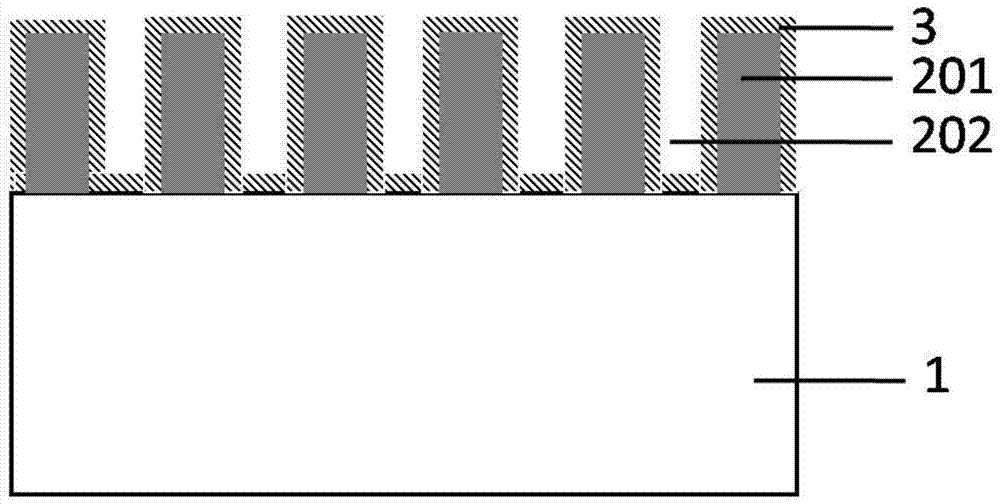

High light output scintillator surface photonic structure and preparation method

A photon structure and scintillator technology, applied in the field of nuclear radiation detection, can solve the problems of insufficient combination of surface structure and scintillator, uncertain optical properties, small covering layer thickness, etc., to achieve enhanced light extraction efficiency and scintillation light output The effect of high, high flicker light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

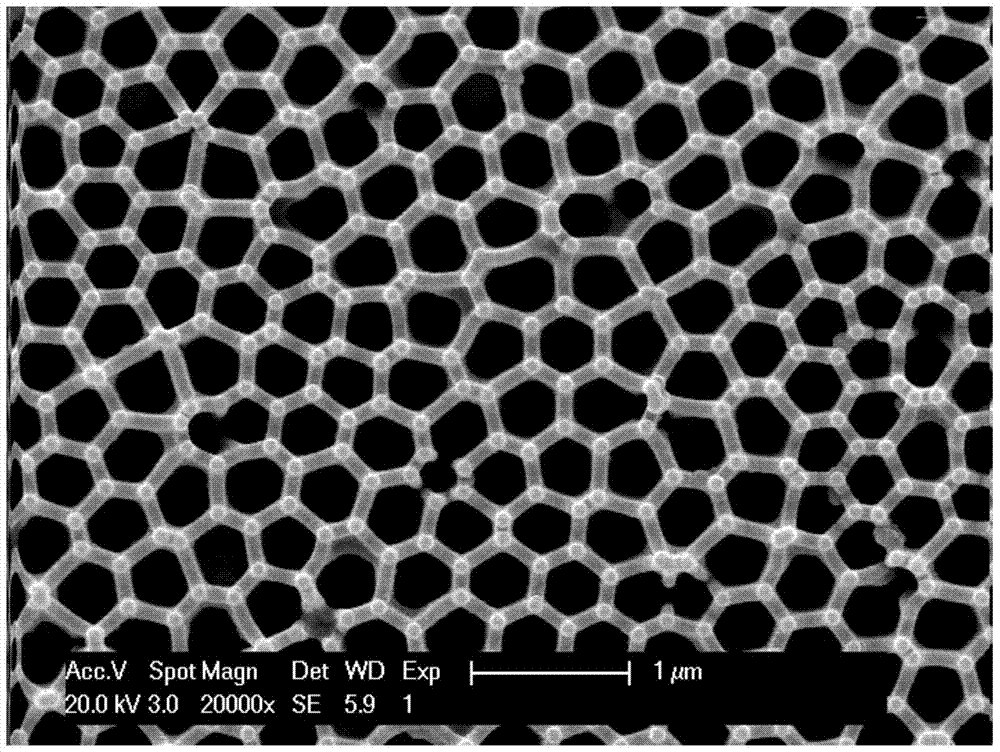

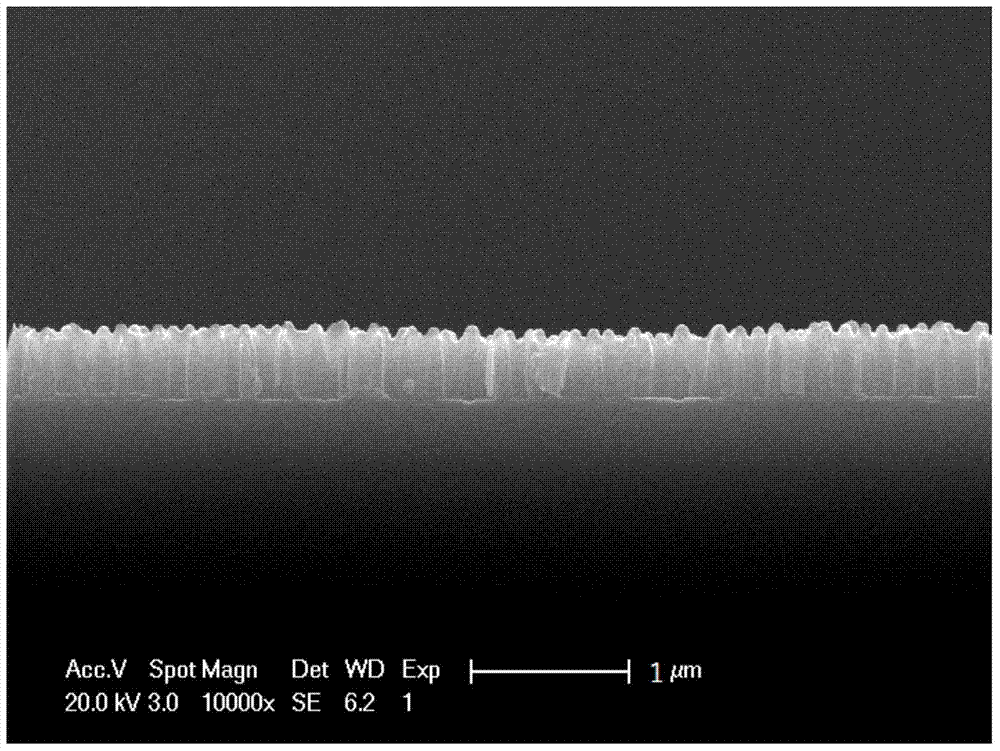

[0034] Cut and polished to a size of 3×3×2cm 3 of (Lu,Y) 2 SiO 5: Ce scintillator, the emission center wavelength of the scintillator is 420nm. A two-step electrochemical anode process was used to prepare a transplantable double-pass porous anodic aluminum oxide film: a high-purity aluminum foil with a purity of 99.99wt% after vacuum annealing at 500°C for 2 hours was used as the anode, and a graphite plate was used as the cathode, with a concentration of 0.2mol The citric acid solution per liter is used as the electrolyte, and the aluminum foil is oxidized for the first time at a temperature of 10°C and a voltage of 250V, and the oxidation time is 1 hour; soaked in a mixed solution of 6.0% phosphoric acid and 1.8% chromic acid After the first oxidation of the aluminum foil for 3 hours, the barrier layer of porous alumina was removed to obtain a double-pass porous structure; then the second oxidation process was carried out under the same conditions as the first oxidation pr...

Embodiment 2

[0036] In this example, the size is 5×5×1cm 3 Bi 4 Ge 3 o 12 A scintillator, the emission center wavelength of the scintillator is 510nm. A two-step electrochemical anode process was used to prepare porous anodic aluminum oxide films: a high-purity aluminum foil with a purity of 99.99 wt% after vacuum annealing at 500 ° C for 2 hours was used as the anode, a graphite plate was used as the cathode, and lemon with a concentration of 0.5 mol / l was used. The acid solution is the electrolyte, and the aluminum foil is first oxidized at a temperature of 0°C and a voltage of 280V, and the oxidation time is 2 hours; the first oxidation is soaked in a mixed solution of 6.0% phosphoric acid and 1.8% chromic acid After 4 hours of aluminum foil, the barrier layer of porous alumina was removed to obtain a double-pass porous structure; then the second oxidation process was carried out, the conditions were consistent with the first oxidation process, and the time was 3 minutes; finally the...

Embodiment 3

[0038] This example is basically the same as Example 2, the difference is that the average pore spacing of the prepared porous anodic aluminum oxide film is about is 408nm, the average pore diameter is about 204nm, the height is 149nm, and the atomic layer deposition thickness of the high refractive index conformal dense layer is 122nm. The luminescence spectrum of the prepared sample has a certain enhancement near the peak and the whole spectrum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com