A scraping system for isolating grids

A technology of separating screen and scraper, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of using a single, unable to scrape the mesh grid at the same time, and the scraping width of the scraper cannot be adjusted, etc., and achieves good practicability. , Intuitive indication, good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

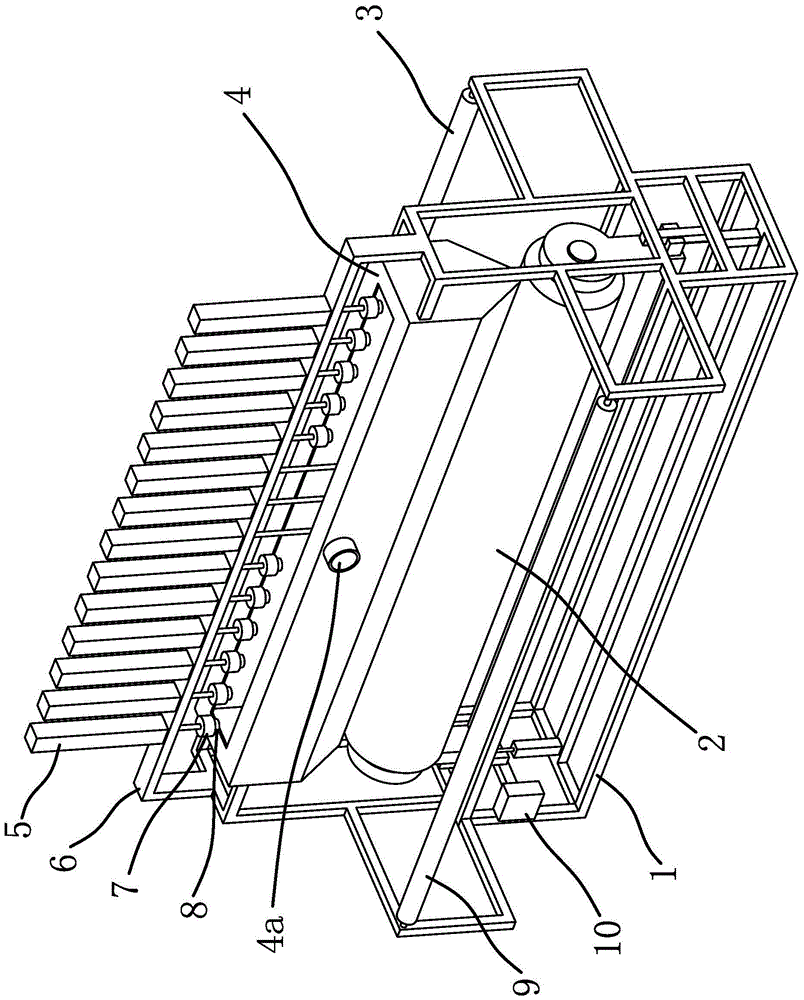

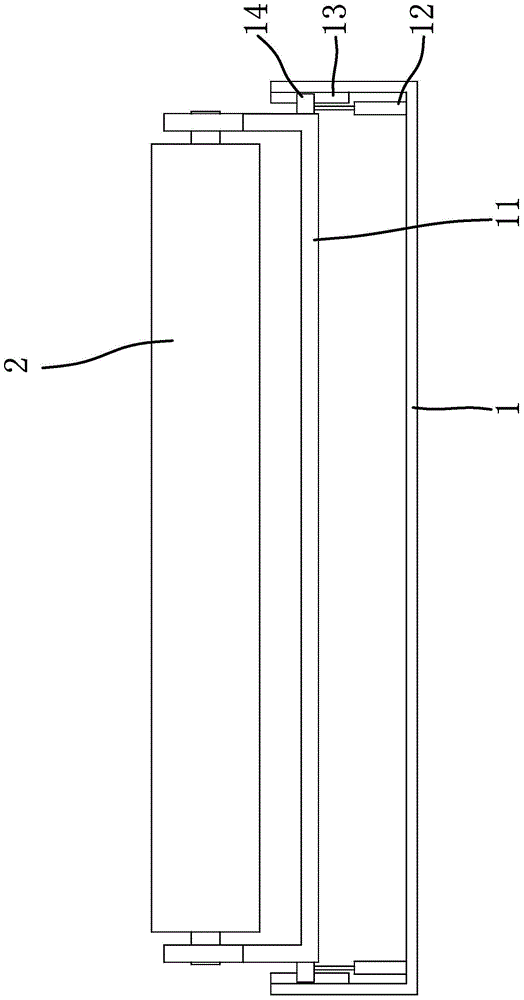

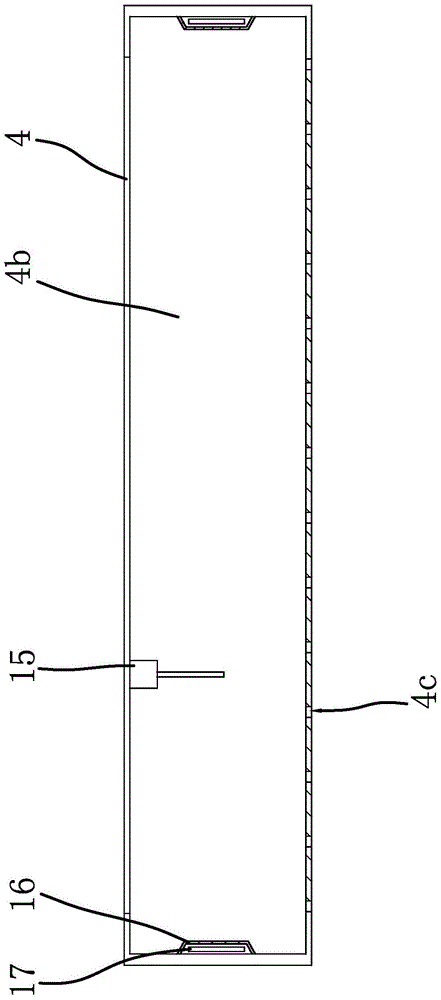

[0039] Such as figure 1 , image 3 As shown, the scraping system for isolating grids includes a frame 1, a scraper 4 is fixed on the frame 1, and a scraper 4 is fixed on the frame 1 through bolt connection; the scraper 4 has a working chamber 4b inside, The side of the scraper 4 has a feeding hole 4a that communicates with the working chamber 4b. The frame 1 is provided with a feeding mechanism that can deliver paint to the feeding hole 4a. The lower part of the scraper 4 has a number of discharge holes that communicate with the working chamber 4b. Holes 4c, in the present embodiment, the quantity of discharge holes 4c is twenty; The frame 1 is also provided with a control mechanism that can close any discharge holes 4c, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com