Edge-turning machine for arc slabs

A technology of flanging machine and circular arc plate, which is applied in the field of circular arc plate flanging machine, can solve the problems of large size and shape error of parts, unguaranteed dimensional consistency, high mold cost and processing cost, etc., and achieve good dimensional consistency , Improve labor productivity, reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

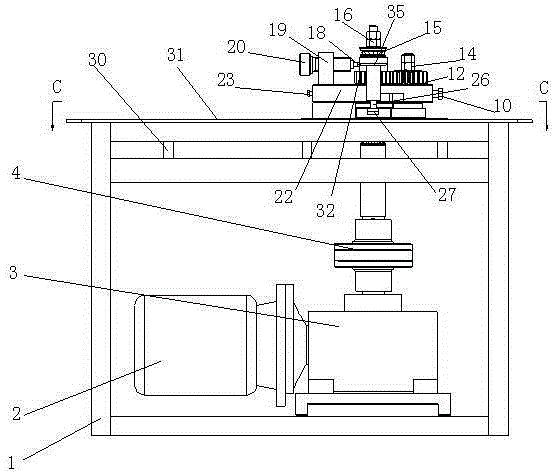

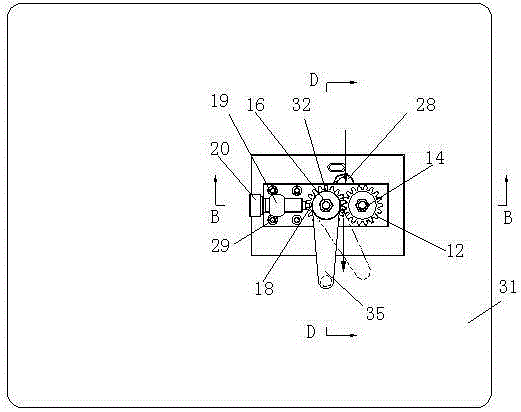

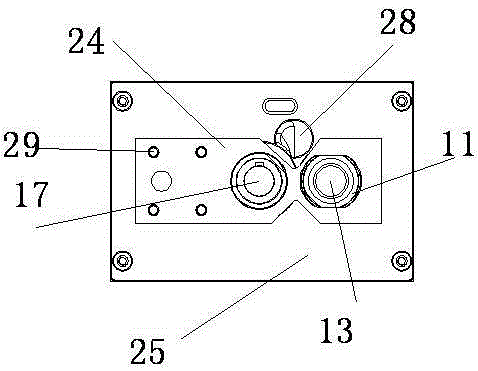

[0023] see Figure 1~Figure 5 , a kind of arc plate flanging machine that the present invention relates to, it comprises frame 1, and the top of frame 1 is provided with work surface 31, and the inside of frame 1 is provided with motor 2, reducer 3 and coupling 4, The output end of the motor 2 is connected to the input end of the reducer 3, and the output end of the reducer 3 is connected to a vertically arranged driving shaft 17 through a coupling 4, and a horizontally arranged lower cover plate is arranged at the center of the top of the frame 1 25. The lower cover plate 25 is connected to the frame 1 through the fixing plate 30 below it, and the upper cover plate 22 is arranged directly above the lower cover plate 25, between the left section of the upper cover plate 22 and the left section of the lower cover plate 25 A backing plate 24 is provided, and the upper cover plate 22 , the backing plate 24 and the lower cover plate 25 are connected and fixed by four vertically ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com