Tool device for fixing small machined end of conical sleeve

A technology of tapered sleeves and tooling, which is applied in the direction of expanding the mandrel, etc., which can solve the problems of high cost of use, easy distortion and cracking of copper tapered sleeves, and achieve the effect of avoiding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

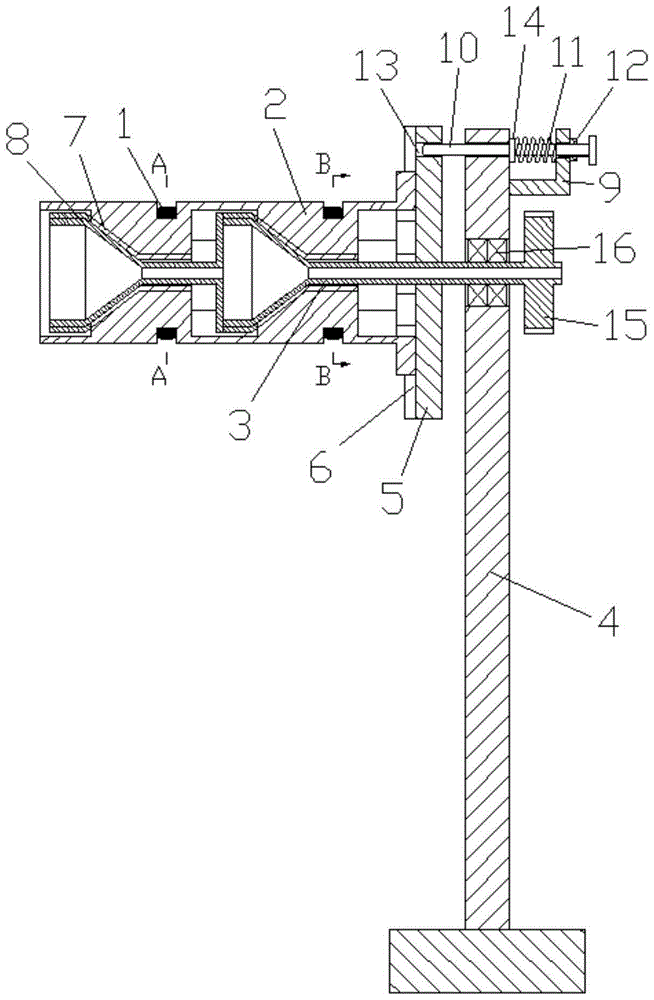

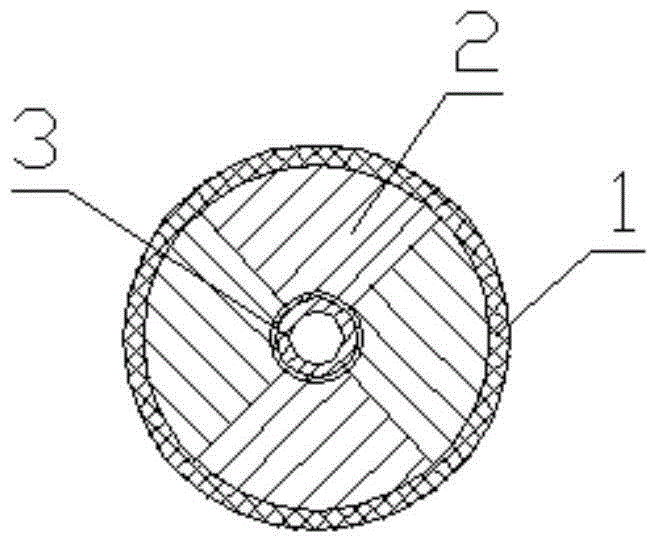

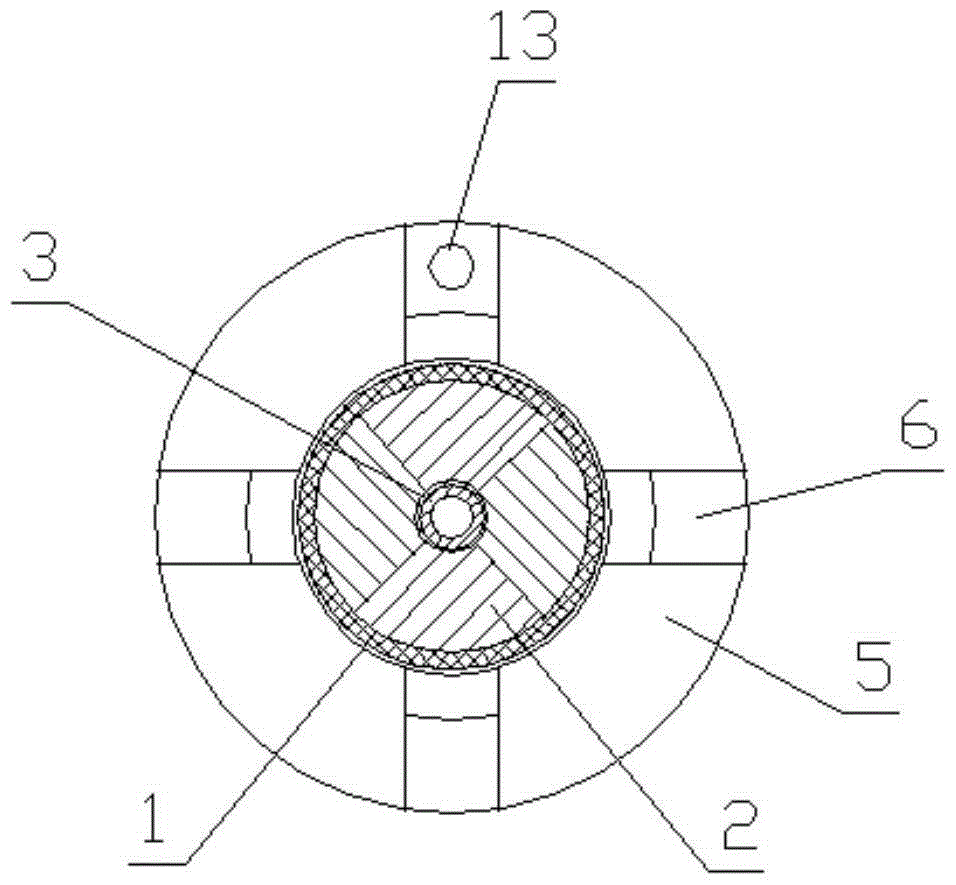

[0015] Such as Figures 1 to 3 As shown, a tooling device for fixing the small end of the tapered sleeve, including an elastic sleeve 1, an expansion body 2, a driving rod 3, a support frame 4, a limit block 5 arranged at one end of the expansion body 2, a bracket 9, a screw rod 10, Spring 11 and lock nut 12. The outer surface of the expansion body 2 is provided with at least two annular grooves along its circumferential direction. In this embodiment, the expansion body 2 is provided with two annular grooves, and the elastic sleeve 1 is set in the annular grooves. The limiting block 5 is a plate-shaped structure, the limiting block 5 is radially provided with chute 6, and the cross section of the expansion body 2 is a valve ring structure with at least three petals. One end of the valve annulus of the ring structure is set in the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com