Mechanically clamped type fir tree blade-root milling cutter

A clip-on, fungus-type technology, applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of reduced use cost, inability to use general-purpose blades, and increased manufacturing costs of blades to achieve effective and stable processing and reduce Effect of Vibration and Roughness Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

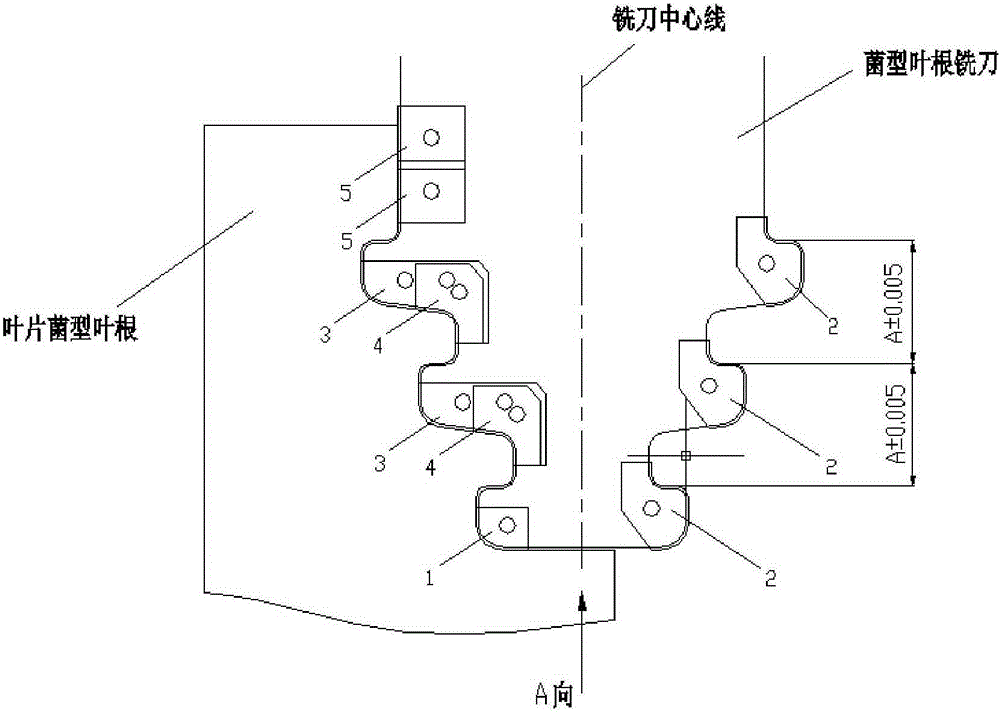

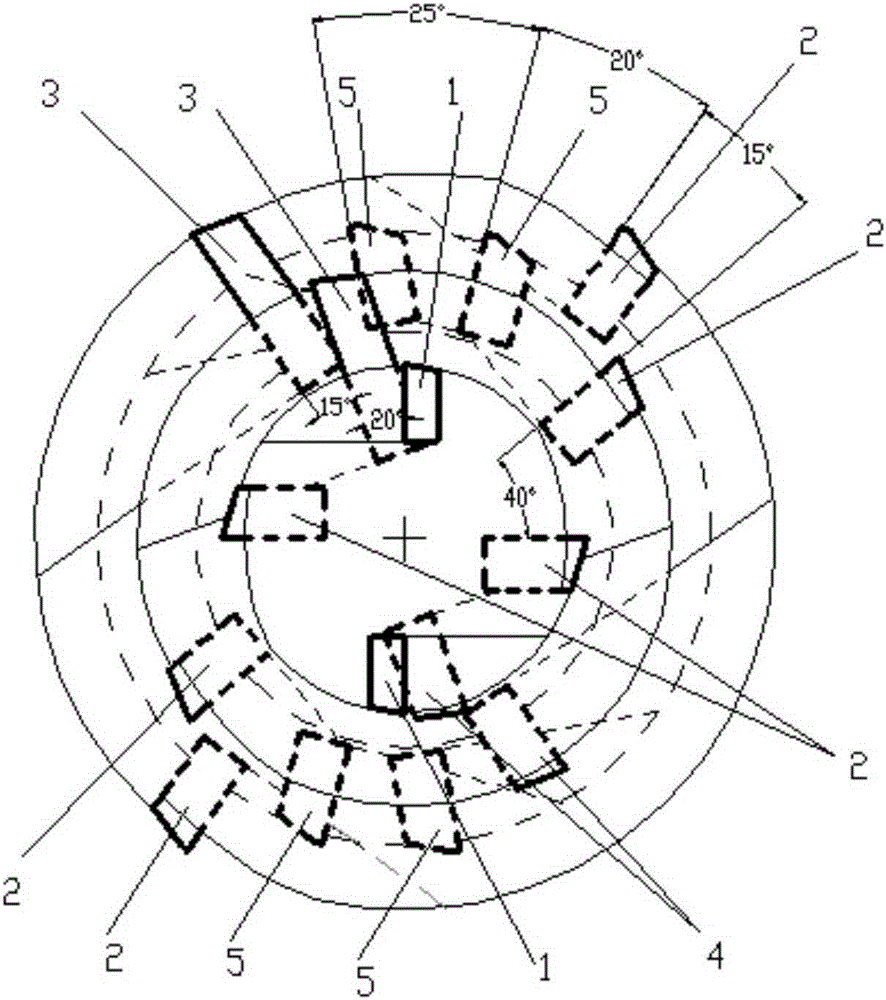

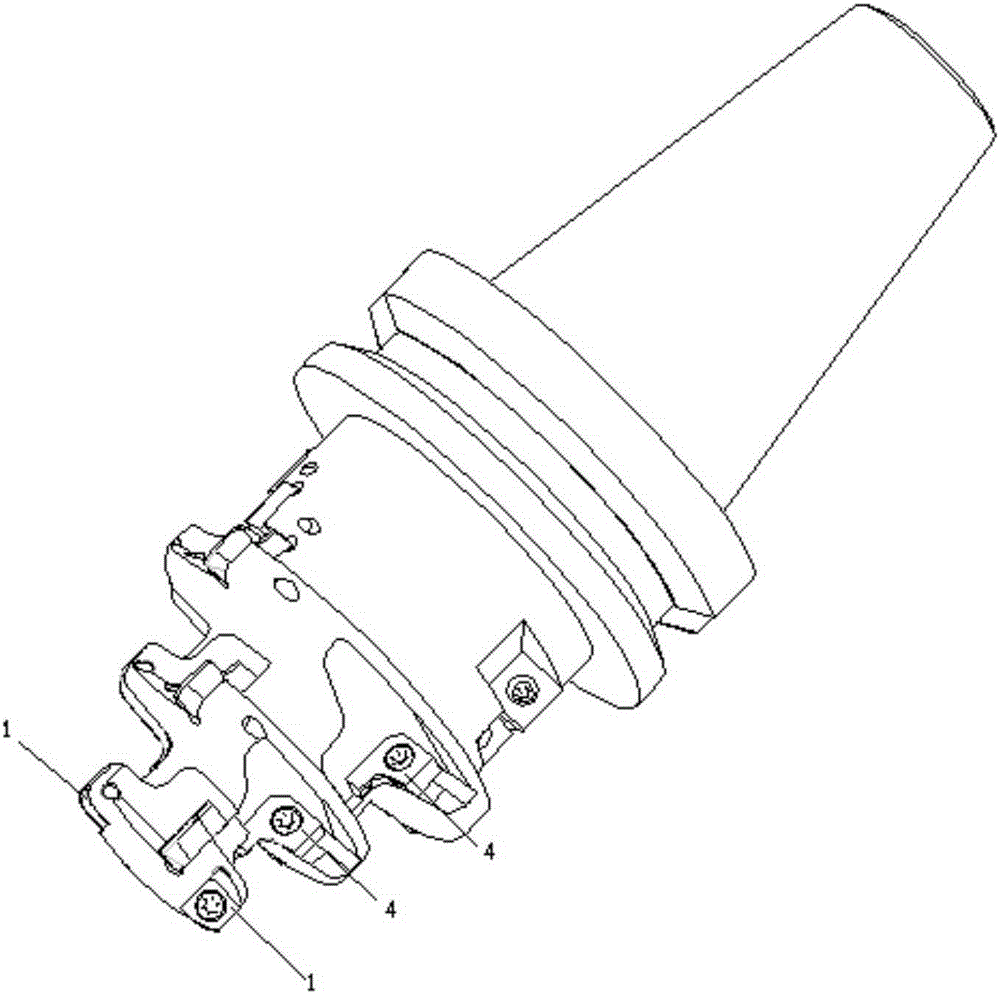

[0012] A kind of machine-clip fungus-type leaf root milling cutter, such as Figure 1 to Figure 5 As shown, including: No. 1 blade 1, No. 2 blade 2, No. 3 blade 3, No. 4 blade 4 and No. 5 blade 5, etc. The specific setting positions and angles of the blades in the cutter body are as follows:

[0013] Two No. 1 blades 1 are arranged in the first row of blade grooves, and they are symmetrically distributed about the center. No. blades are end face blades, which are used to process end faces;

[0014] Two No. 2 blades 2 are arranged in the second row of sipes, symmetrically distributed about the center, and the blade profile is taken from the theoretical contour profile of the fungus leaf root, and the included angle with the No. 1 blade is 90°, and the rake angle is 0°. The surface is evenly passed through the center;

[0015] The No. 3 blade 3 and the No. 4 blade 4 are arranged in the third row of sipes, which are distributed symmetrically about the center and arranged in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com