Lift type concrete mixing and transporting semitrailer

A technology for mixing and transporting concrete, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of high vehicle center of mass, poor economy, waste of concrete materials, etc., achieve convenient operation of feeding and discharging materials, and prevent water loss , the effect of low vehicle height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

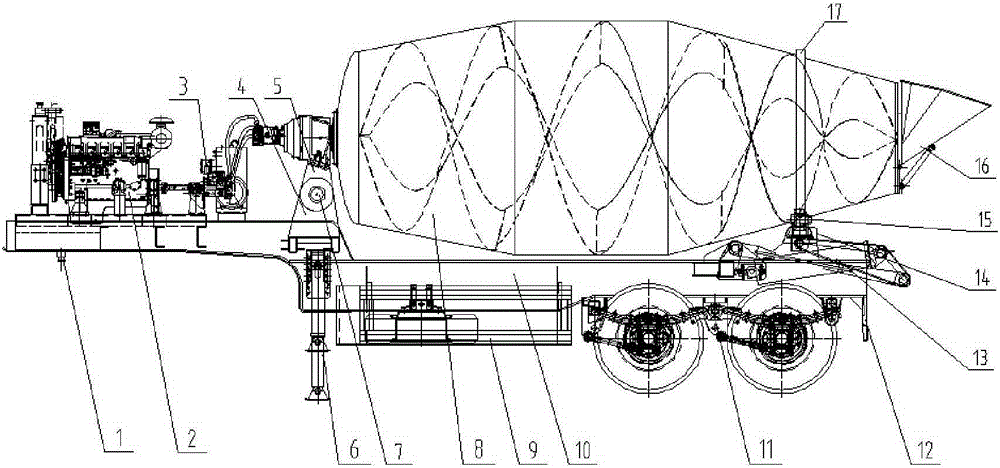

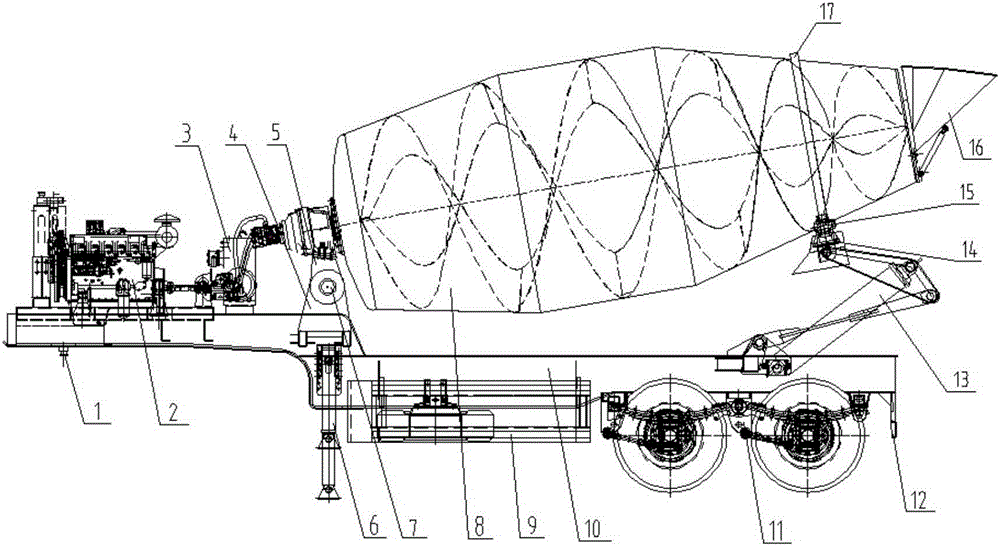

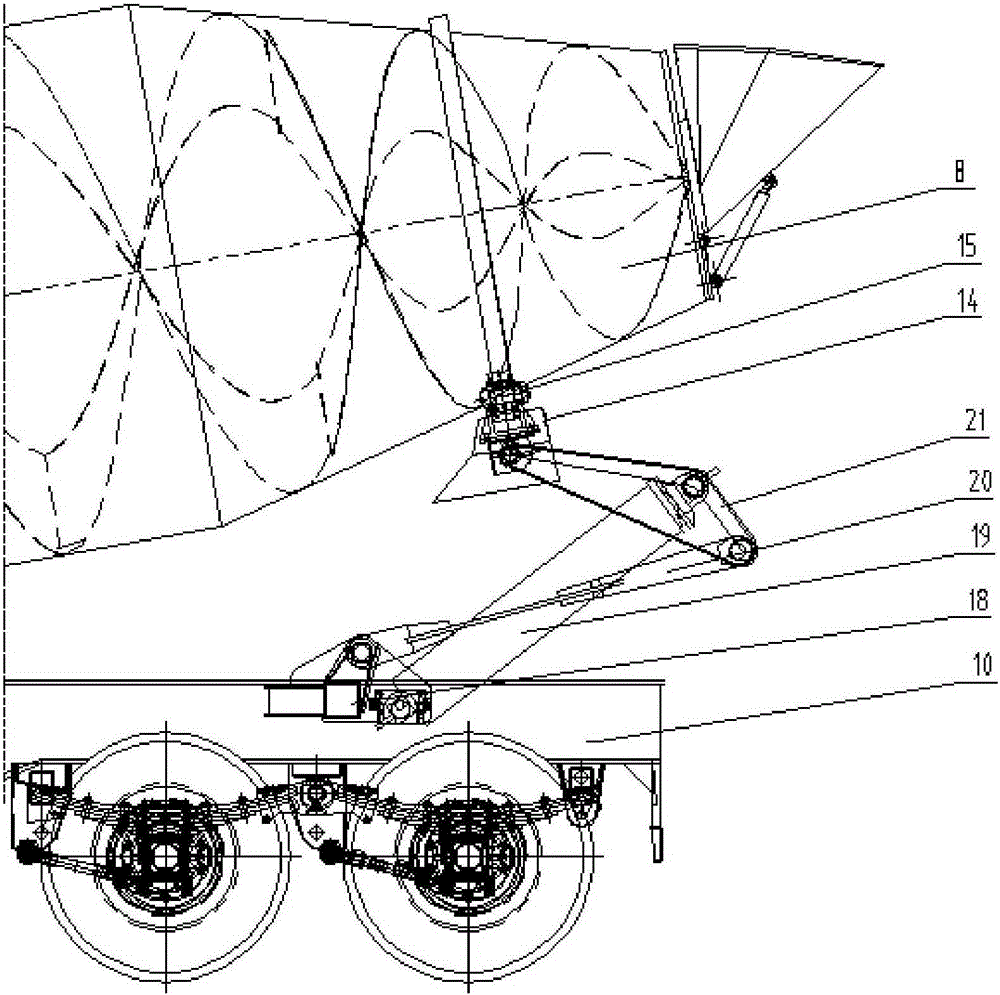

[0017] Referring to the accompanying drawings, an elevating concrete mixing transport semi-trailer includes a frame assembly 10, a traction device 1, a power system 2, a power transmission system 3, a front support device, a support device 6, a mixing drum 8, and a side protection device 9. Suspension system 11, rear protection device 12, oil cylinder jacking device 13, rear frame 14, rear support device and feeding and discharging system 16, the frame assembly 10 is a stepped gooseneck structure, which can effectively reduce the height of the vehicle, The front supporting device includes upper and lower brackets 5, 4 and a rotating shaft 7, the lower bracket 4 is fixedly welded on the front part of the vehicle frame assembly 10, the upper and lower brackets 5, 4 are connected by rotating shaft 7, and the front end of the mixing drum 8 rotates Installed on the upper bracket 5, a speed reducer is installed on the upper bracket 5, thereby driving the mixing drum 8 to rotate;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com