Retractable type non-inflatable wheel allowing ground contact area of tire tread to be changed

A grounding area, non-inflatable technology, applied in the direction of auxiliary wheels/rings, etc., can solve the problem that the tire cannot adjust the tire grounding area, etc., to achieve the effect of improving adhesion, reducing the tire grounding area, and driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

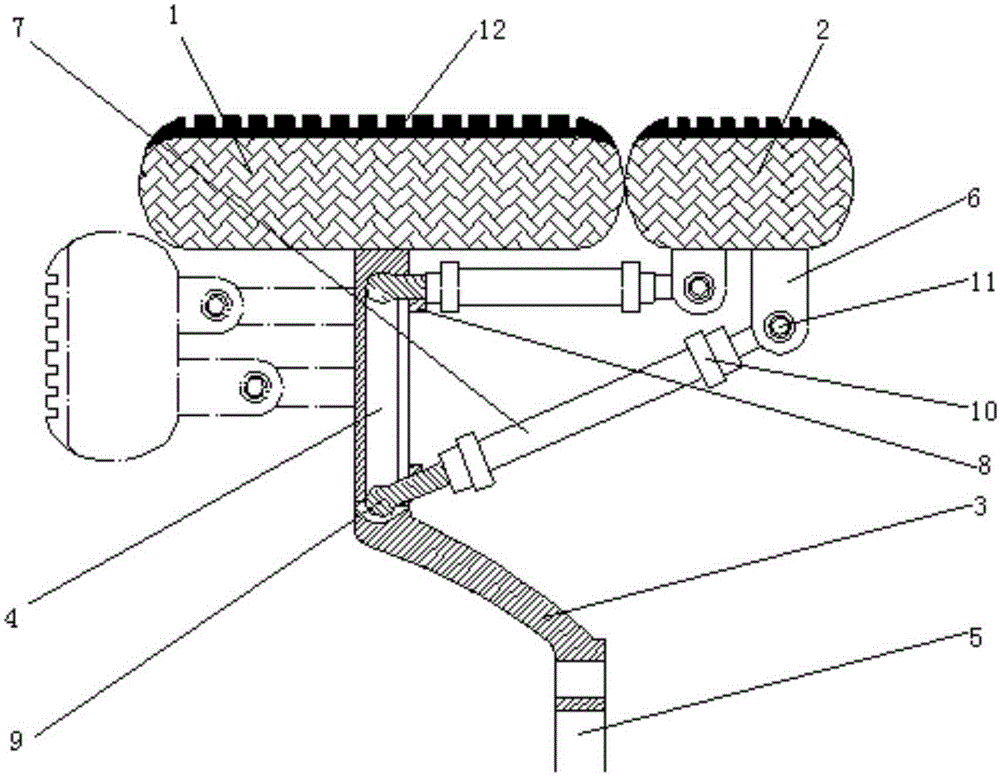

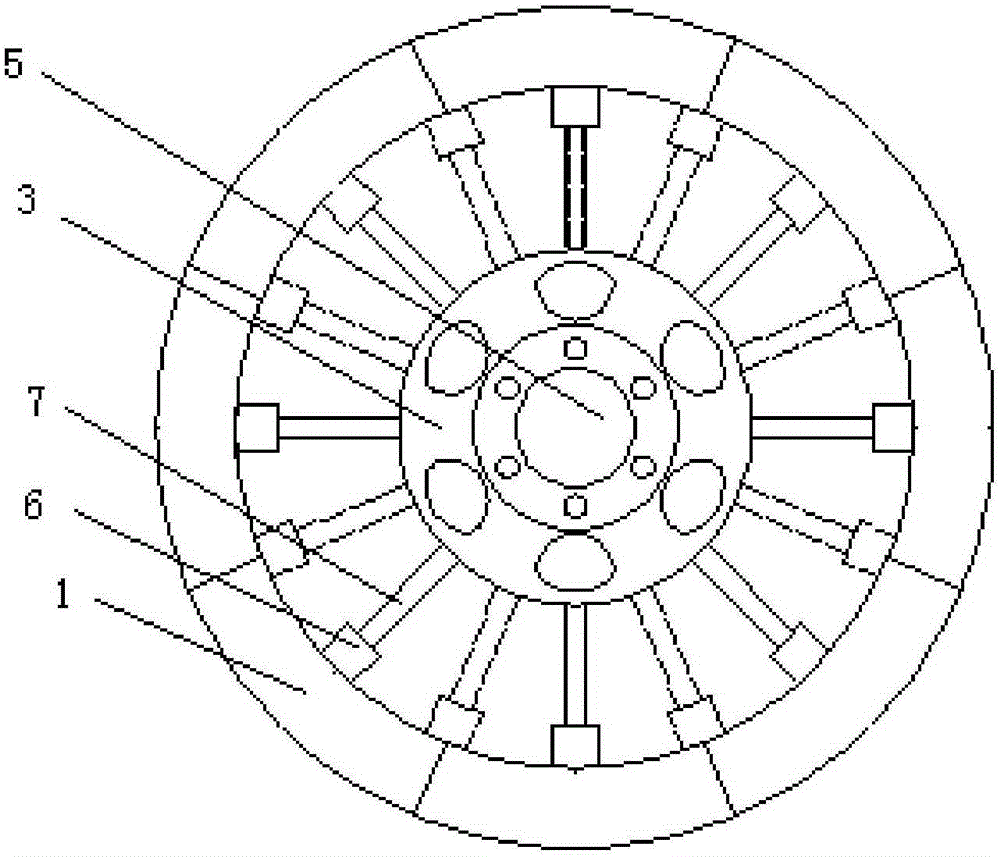

[0029] like figure 1 and 2 The shown retractable non-pneumatic wheel with variable tread contact area includes a main wheel 1, an auxiliary wheel 2, a wheel retractable mechanism and a wheel web 3, and the main wheel 1 and the auxiliary wheel 2 are coaxially arranged , the main wheel 1 is an integral non-pneumatic elastic wheel, the auxiliary wheel 2 is a non-pneumatic wheel divided into several equal parts along the circumferential direction, the main wheel 1 is connected to the wheel shaft through the wheel web 3, The wheel web 3 is provided with a hinged sliding guide groove 4 which is the same as the sum of the number of sections of the auxiliary wheel 2 along the circumference, and the hinged sliding guide groove 4 extends from the wheel web center hole 5 to the wheel web 3 extending in the radial direction, one end of the wheel retractable mechanism is connected in the hinged sliding guide groove 4, and the other end is connected with the auxiliary wheel 2.

[0030] Se...

Embodiment 2

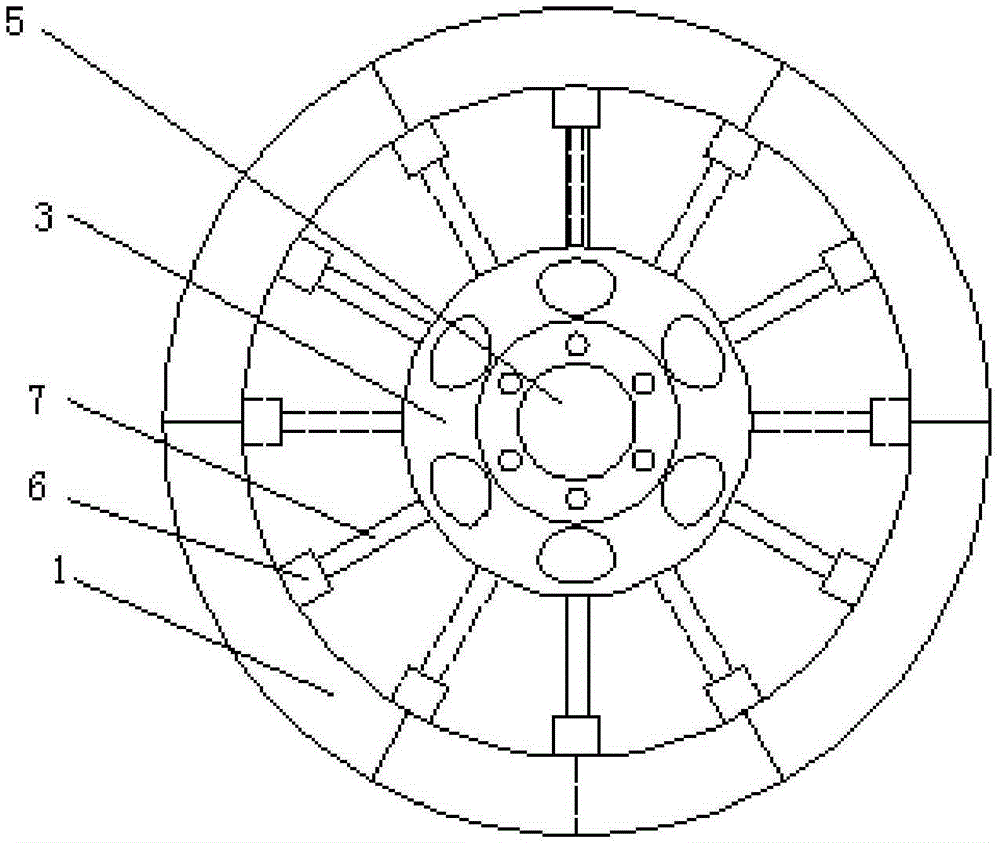

[0037] like figure 1 and 3 The shown retractable non-pneumatic wheel with variable tread contact area includes a main wheel 1, an auxiliary wheel 2, a wheel retractable mechanism, and a wheel web 3. The main wheel 1 and the auxiliary wheel 2 are coaxially arranged , the main wheel 1 is an integral non-pneumatic elastic wheel, the auxiliary wheel 2 is a non-pneumatic wheel divided into several equal parts along the circumferential direction, and the main wheel 1 is connected to the wheel shaft through the wheel spoke plate 3, The wheel web 3 is provided with a hinged sliding guide groove 4 which is the same as the sum of the number of sections of the auxiliary wheel 2 along the circumference, and the hinged sliding guide groove 4 extends from the center hole 5 of the wheel web to the wheel web 3 extending in the radial direction, one end of the wheel retractable mechanism is connected in the hinged sliding guide groove 4, and the other end is connected with the auxiliary wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com