Self-propelled type work platform with corrugated beam barrier of highway as guide rail and obstacle crossing function

A corrugated beam guardrail and highway technology, applied in the field of work platform and self-propelled work platform, can solve the problem of small contact area, practicality and operability discount, limit the structure of the whole machine, the running speed of the load and the amount of vibration, etc. problems, to achieve the effect of high degree of automation, improved operation speed, strong practicability and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

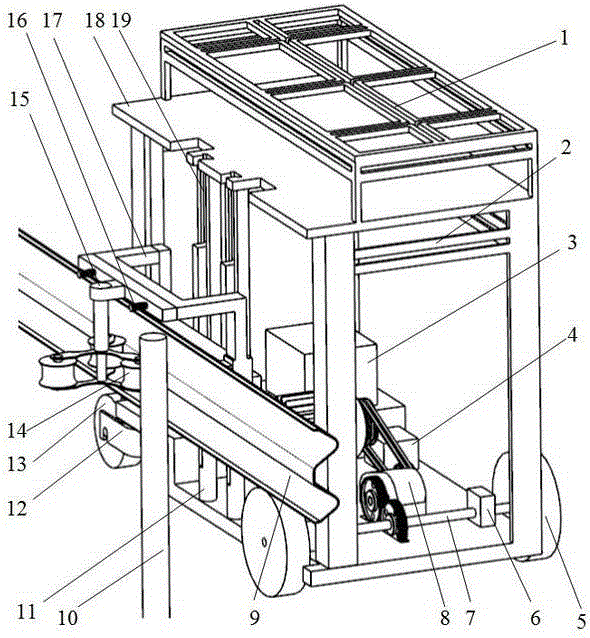

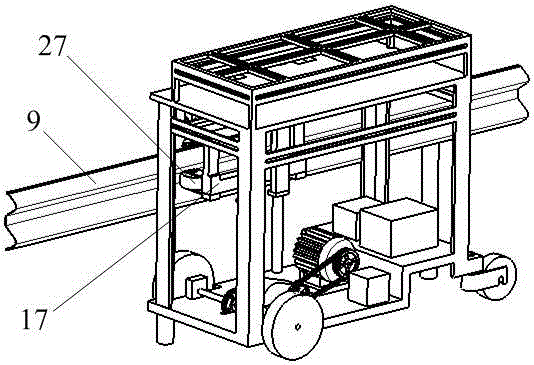

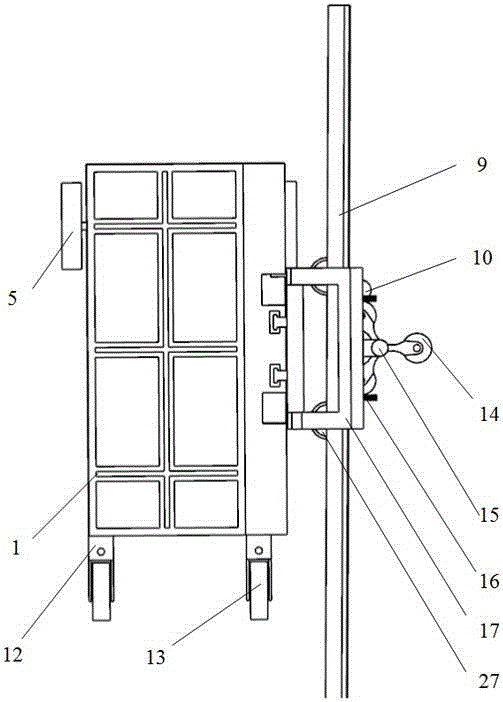

[0021] refer to Figure 1~Figure 5 , the self-propelled work platform with the wave-beam guardrail of the expressway as the guide rail and the obstacle-crossing function includes a railing guide device, a planetary obstacle-crossing device, a load-carrying walking device, and a power transmission device, wherein the railing guide device includes a shock absorber 11, Slide rail 19, external hanger 17, inner profiling wheel 27, a pair of shock absorbers 11 are vertically installed on the side of car body 18 close to wave beam guardrail 9, all are provided with damping spring 28 in each shock absorber 11 , the car body 18 above each shock absorber 11 is vertically fixed with a slide rail 19 of a certain length, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com