Frame stacking type conveyer achieving manual horizontal pushing and power vertical conveying

A conveyor and horizontal pushing technology, applied in the direction of lifting devices, etc., can solve the problems of low handling efficiency, frequent back and forth walking, and a large amount of items, and achieve the effects of simple and reliable mechanical movement, good air environment, and short working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

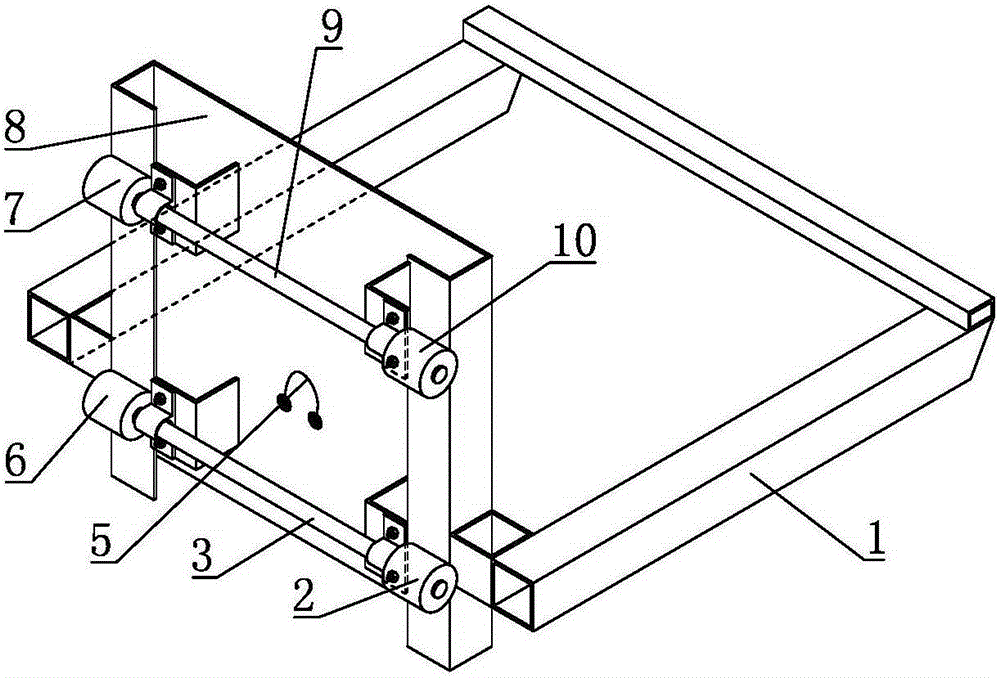

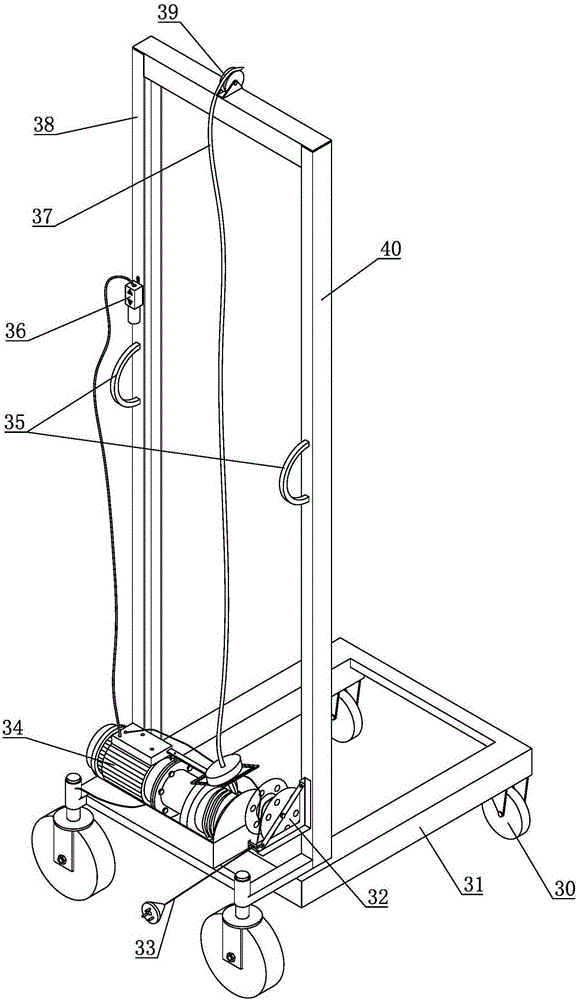

[0025] Manpower flat pushes, and power conveys stacked frame type conveyer up and down, comprises the frame (31) of belt wheel (30), and steel rope electric hoist (34) is installed on the frame (31). Also comprise main guide rail frame (50), auxiliary guide rail frame (51), carriage car (52).

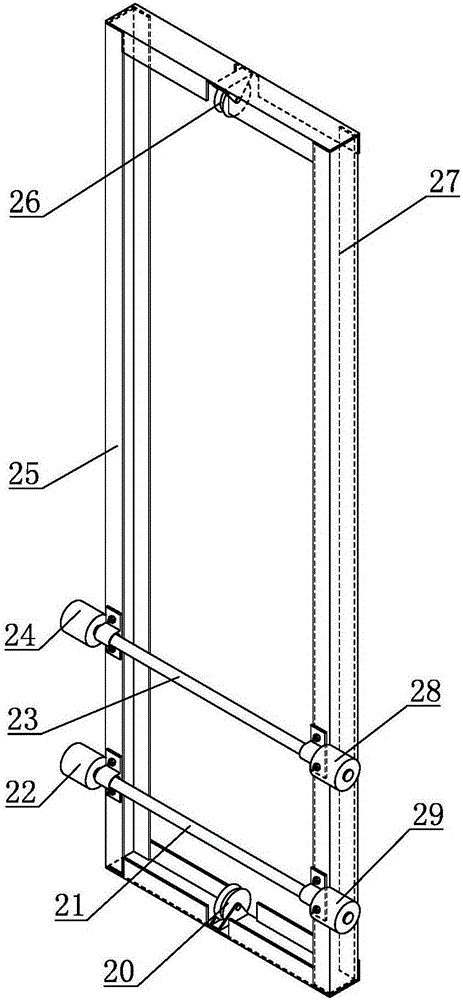

[0026] The first fixed pulley (39) is with the main rail frame (50) top, and the bottom is connected and fixed with the frame (31). One embodiment is that the main rail frame (50) takes a vertical orientation to reduce the material, weight and volume of the fuselage required to lift the unit height in the load. The left main frame part (40) and the right main frame part (38) of the main rail frame (50) are with the secondary guide rail frame left wheel groove and the secondary guide rail frame right wheel groove respectively. The left main frame part (40) and the right main frame part (38) are in a straight line structure and have two functions, one is to support the load in the load; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com