Integral Waste Plastic Refining Unit

An oil refining unit and integrated technology, which is applied in the field of garbage disposal equipment, can solve problems such as difficulty in sealing the slip-knot, achieve novel structure, and reduce solid impurities and odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

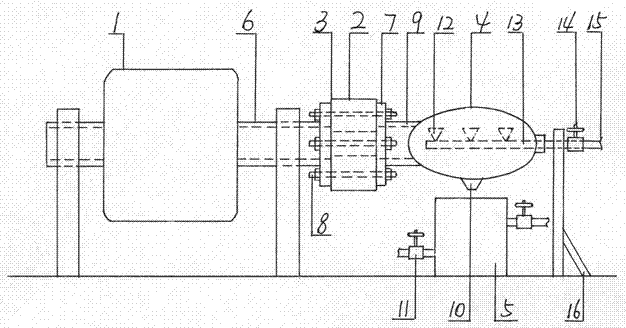

[0015] Such as figure 1 As shown, an integrated waste plastic oil refining device is used to solve the above problems. The device is refitted on the basis of the above-mentioned rotary furnace. , condenser 4 and oil-water separator 5 are connected to form;

[0016] On the flange 7 of the gas delivery pipe 6 of the rotary furnace 1, a section of heat insulation pipe 2 is connected. The heat insulation pipe 2 is a section of cylinder made of hard wood, and the outer diameter of the heat insulation pipe 2 is greater than or equal to the gas delivery pipe. The outer diameter of the flange 7 of 6, the inner diameter of the heat insulating pipe 2 is less than 1 cm of the inner diameter of the gas pipeline 6; in order to prevent the condensed oil from flowing back into the rotary furnace 1; There are several thread holes, the thread holes are through holes, and the positions of the thread holes and the thread holes on the flange 7 are matched, and the bolts 8 are respectively penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com