Direct-fired waste plastic refining plant

A refinery device, direct-fired technology, applied in the field of white waste treatment equipment, can solve the problems of insufficient treatment capacity to eliminate white pollution, slow heating speed, high production cost, etc., and achieve novel structure, fast cracking speed and high refining efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

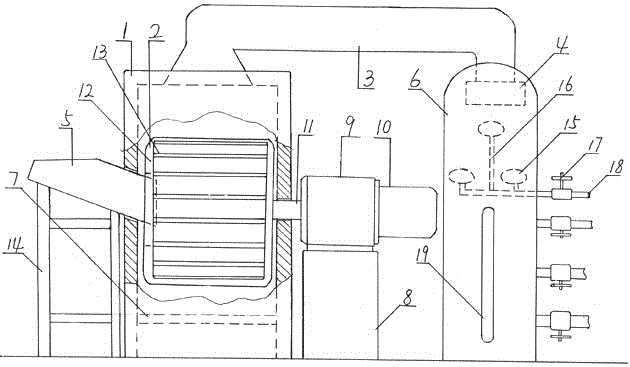

[0018] like figure 1 As shown, a direct-fired waste plastic refining device is composed of a furnace 1, a furnace 2, an induced draft pipe 3, an induced draft fan 4, a feeding dustpan 5 and a spray tower 6;

[0019] Furnace 1 adopts cuboid masonry hearth or iron box-type closed furnace. The cross-section of furnace 1 is U-shaped with the opening downward; furnace 1 uses anthracite lump coal as fuel to reduce heating costs and reduce coal ash in the furnace. The content in the oil; the grate 7 of the furnace 1 is distributed along the lower part of the furnace 1, and the flame on the grate 1 can surround half of the furnace 2; thereby increasing the heating rate of the plastic;

[0020] A furnace 2 is installed in the furnace 1, and the furnace 2 is installed on the longitudinal axis of the center of the furnace 1; the furnace 2 is a rotatable cage; its shape is similar to the fan in the fan system of the indoor unit of the cabinet air conditioner The overall structure of fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com