An improved washing tower for industrial waste gas treatment

A technology for industrial waste gas and waste gas washing, applied in the field of washing towers, can solve the problems of limited effect of washing waste gas and increased difficulty in recycling waste water, and achieve the effect of reducing the difficulty of reuse, improving the effect and efficiency, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

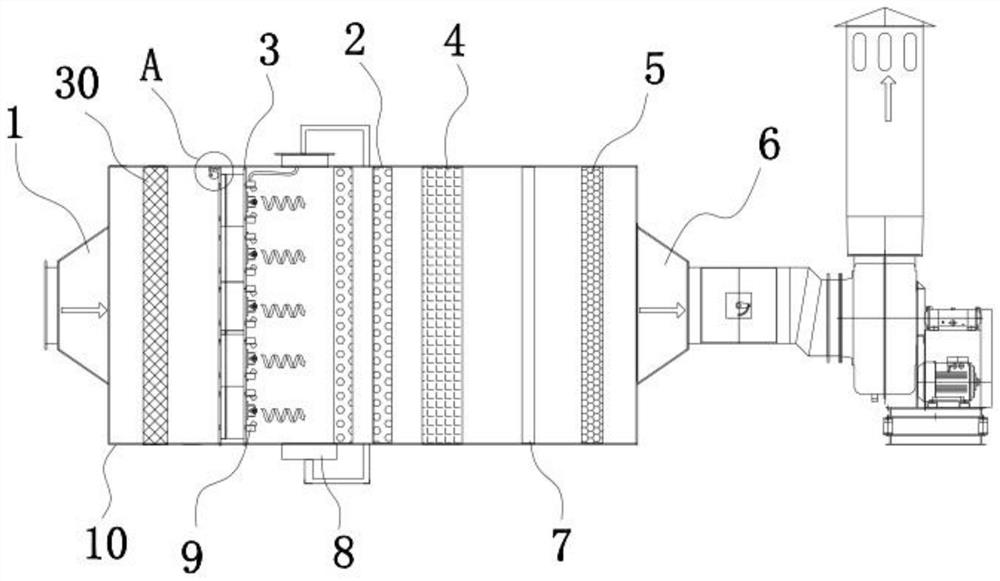

[0045] Such as Figure 1-Figure 3 As shown, an improved washing tower for industrial waste gas treatment includes a tower body 10, a waste gas washing and purification device, a heat recovery device 2 and a waste gas filtering device 3, wherein first air inlets 1 are respectively arranged on both sides of the tower body 10 and the first gas outlet 6, a primary purification device 30 is provided on the side of the waste gas filter device 3 close to the first air inlet 1, the primary purification device 30 is detachably connected to the tower body 10, and the primary purification device 30 can adopt a small-diameter Made of steel wire mesh, it can pre-intercept the fluff or large particle suspension, so as to prevent the purification effect and avoid the subsequent blockage of the exhaust gas filter device 3, and the exhaust gas filter device 3 can adsorb and filter the small solid particles in the exhaust gas , and then through the exhaust gas washing and purification device to...

Embodiment 2

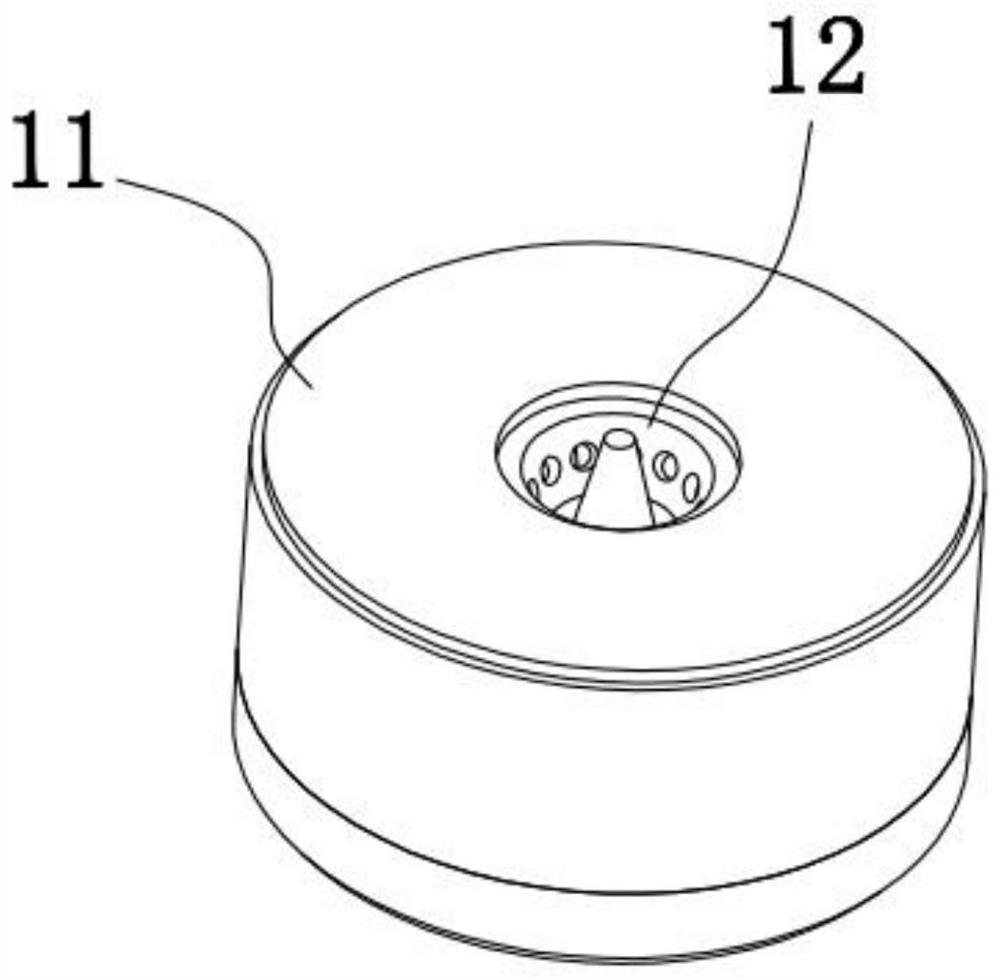

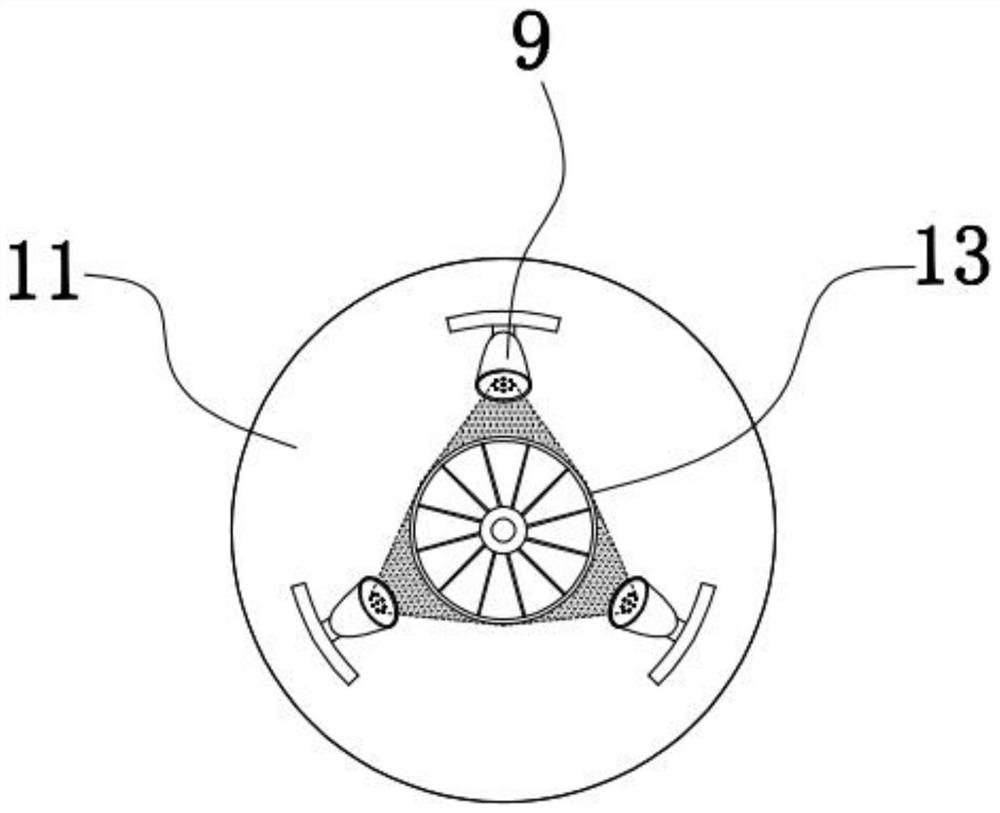

[0050] Such as Figure 7-Figure 11 As shown, the difference between the present embodiment and the first embodiment is that there are at least two filters 11, and exhaust gas filtering devices of different sizes and shapes are carried out between two adjacent filters 11 through the fixing plate 26 and the connecting piece 24. 3 Splicing and assembly to meet the needs of different types of towers 10, by using this filter 11, it can divide the exhaust gas into a single airflow, and then use the baffles 21 in the curved cavity 23 to divide the single airflow again , and carry out independent adsorption and filtration treatment, thereby greatly reducing the content of solid particles in the waste gas, significantly improving the effect of waste gas treatment, and greatly ensuring the utilization rate of waste water, wherein the filter 11 can adopt a cylindrical structure or a square structure, and The fixing plate 26 and the connecting piece 24 are appropriately changed according ...

Embodiment 3

[0052] Such as figure 1 with Figure 12 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that a vibration mechanism is provided on the tower body 10, and the vibration mechanism includes a power element and a reset element that drive the exhaust gas filter device 3 to move back and forth, and its specific operation is in the first The curved cavity 23 of the housing 15 is not filled with the filter sheet 16, and the hollow structure is retained, while the curved cavity 23 of the second housing 19 is filled with the filter sheet 16. When the exhaust gas enters the curved cavity 23, the exhaust gas is in the first The housing 15 can form swirling flow, adsorption and deposition, and after the filter 16 has been used for a period of time, the side of the intake air will reduce the filtering effect of the filter 11 due to the adhesion of solid particles. And the reset element drives the exhaust gas filter device 3 to carry out intermittent rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com