Impact flow washing device for purifying raw gas and purifying process

A washing device and crude gas technology, which is applied in combustible gas purification, combustible gas purification/transformation, gas dust removal, etc., can solve the problem of large space occupied by crude gas purification devices and processes, excessive ash content in chilled water, and low dust removal efficiency and other problems to achieve the effect of ensuring long-term stable operation, improving dust removal efficiency, and reducing dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

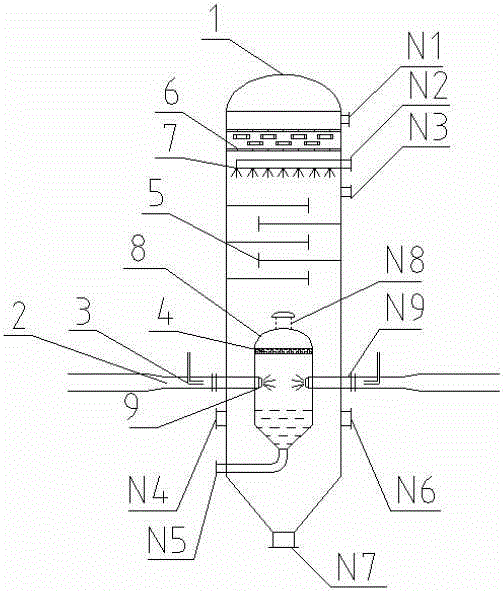

[0036] Such as figure 1 As shown, an impinging stream scrubbing device for purification of crude gas includes an impinging stream scrubbing tower and a reduced-diameter accelerating tube 2 introduced into the tower from the lower side wall of the scrubbing tower shell 1. The upper side is provided with an impingement tower 8, a purification structure, a process condensate distributor 7 and a multilayer plate demister 6, and the side wall of the washing tower shell 1 is provided with a black water outlet N7 and an impinging tower black from bottom to top. Water outlet N5, chilled water outlet N4, washing water outlet N6, crude gas inlet N9, scrubber make-up water inlet N3, process condensate inlet N2 and purified synthesis gas outlet N1; the reduced diameter acceleration tube 2 penetrates into the scrubber through the crude gas inlet N9 In the tower shell 1, the installation position of the reduced-diameter acceleration tube 2 is higher than the chilled water outlet N4, the washi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap