A Side Form Automatic Hooking System

A side mold, automatic technology, applied in the field of mechanical engineering, can solve the problem of difficulty in automatic hooking of side molds, and achieve the effects of improving the laying quality of side molds, being conducive to popularization and application, and being convenient and flexible in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

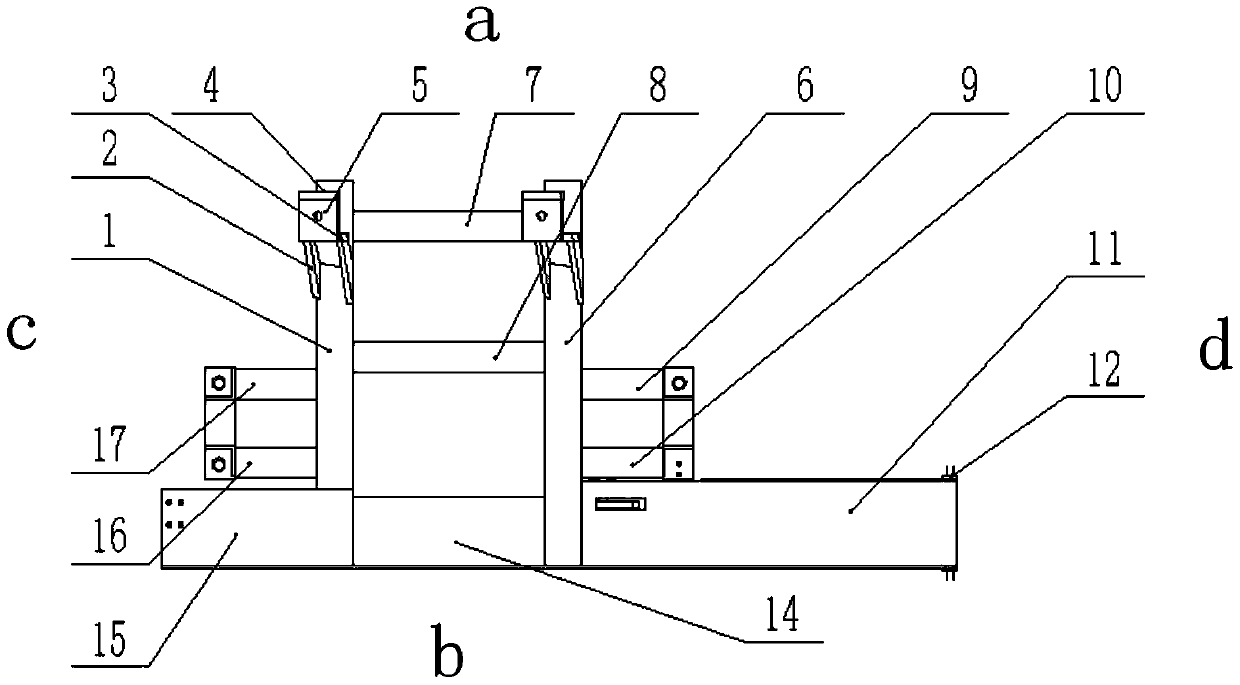

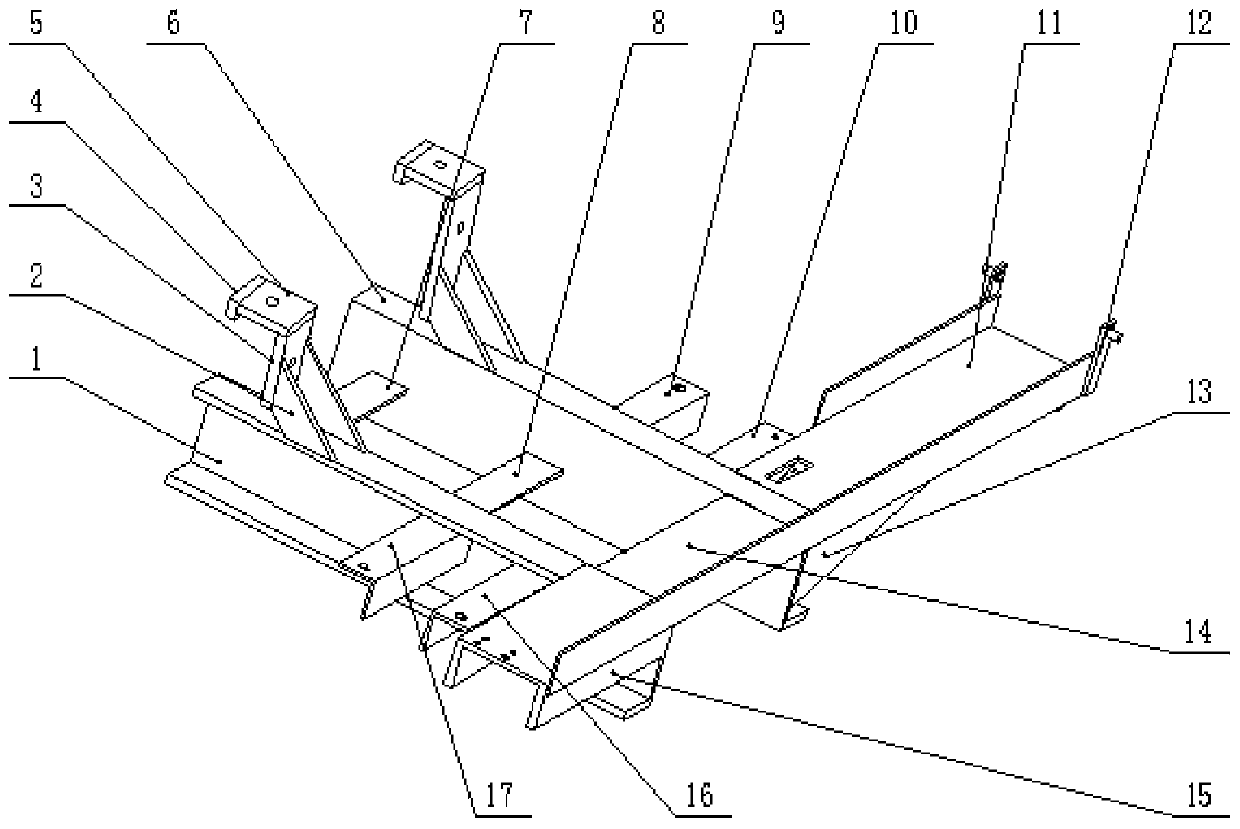

[0058] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0059] Explanation: The automatic hook system is hung on the locomotive. The forward direction of the locomotive is defined as the front, that is, the c direction, and the backward direction is defined as the rear, that is, the d direction; the direction close to the locomotive is defined as the inside, that is, the a direction, which is close to the center of the road where the asphalt is laid ; The side formwork is laid on the edge of the road, which is defined as the outer side, that is, the b direction.

[0060] see Figure 1 to Figure 15 .

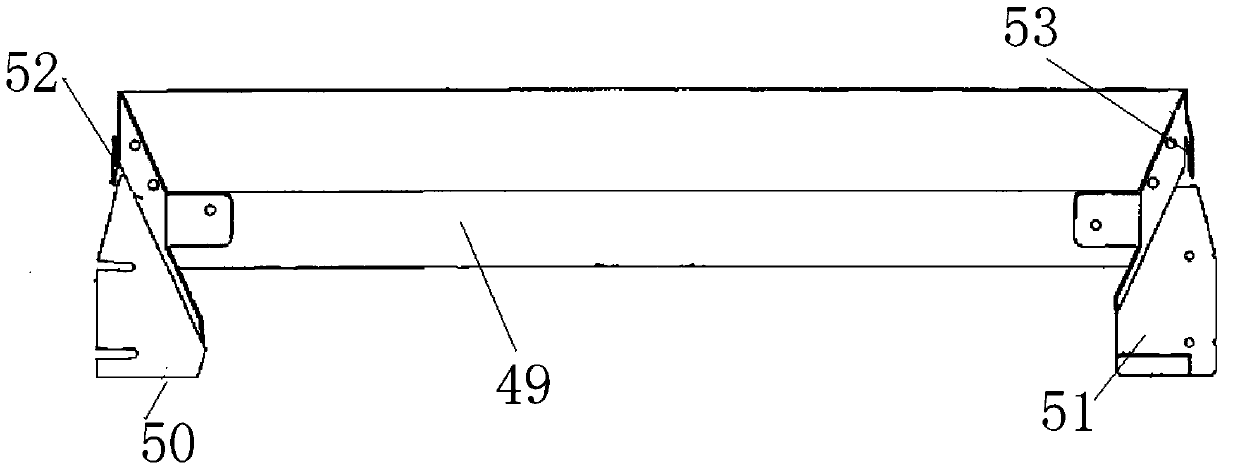

[0061] The present invention is an automatic hooking system for a side mold, comprising a side mold and an automatic hook system, the side mold is composed of a wooden side mold basic body 49, an iron front hook 50, and an iron rear hook 51, and the iron front hook 50 Be fixed on the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com