Bubble point air filter screens/doors

A technology of air filtration and air filtration materials, applied in the field of screen windows/doors, which can solve the problems of inability to isolate fine particles, failure to achieve ventilation effect, failure to open windows for ventilation, etc., to achieve high air filtration efficiency, simple structure and high efficiency The effect of interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

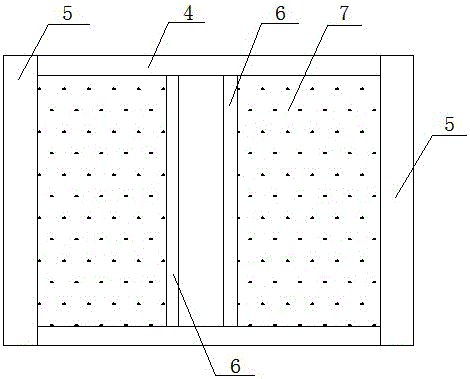

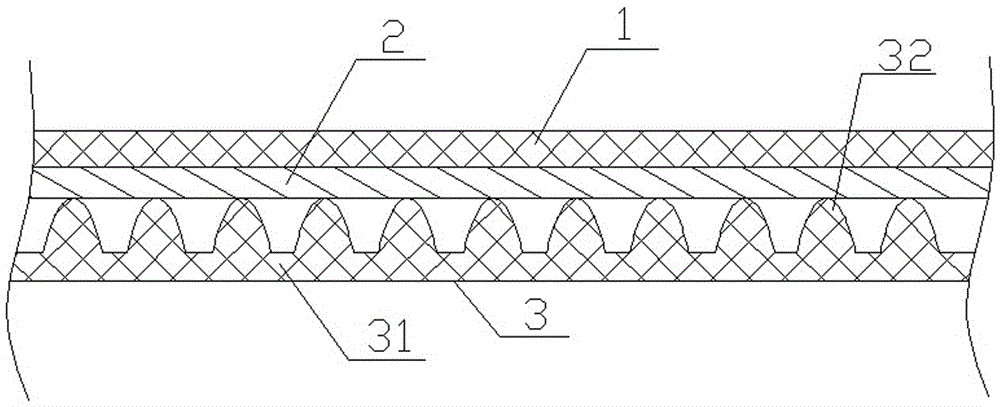

[0038] Such as figure 1 A kind of bubble-point type air filter screen window as shown, comprises window frame 4, and the bubble-point type air filter screen that splits left and right is housed on the window frame, and the left side window (right side window) structure includes reel 5, push-pull Strip 6 and bubble-point air filter yarn 7. One end of the bubble-point air filter yarn is installed in the winding drum, and the other end is connected to a push-pull bar. The push-pull bar can stretch the bubble-point air filter yarn. Both the bar and the push-pull bar on the right side of the window are magnetic, and are connected by magnetic suction when closed. Such as image 3 The bubble-point air filter yarn shown is composed of three layers of plane skeleton material layer, high-efficiency low-resistance air filter material layer and bubble-point skeleton material layer. It has a sandwich structure. The upper layer is plane skeleton material layer 1, and the middle is high-eff...

Embodiment 2

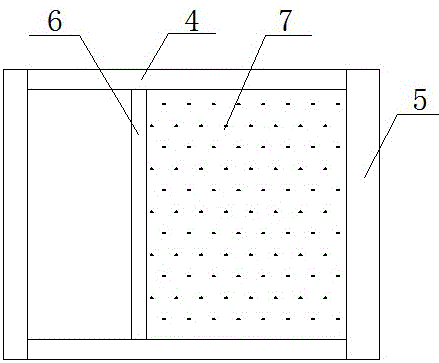

[0053] Such as figure 2 A kind of bubble-point type air filter screen window shown, comprises window door frame 4, and the single-open bubble-point type air filter yarn is housed on the window door frame, and the single-open structure includes winding drum 5, push-pull bar 6 and bubble-point type air filter yarn 7. One end of the bubble-point air filter yarn is installed in the winding drum, and the other end is connected to a push-pull bar. The push-pull bar can stretch the bubble-point air filter yarn. The push-pull bar is magnetic, and the push-pull bar can be adsorbed by magnetic suction when closing On the suction strip on one side of the window and door frame, the suction strip is magnetic and is located on the opposite side of the winding drum.

[0054] Such as image 3 The bubble-point air filter yarn shown is composed of three layers of plane skeleton material layer, high-efficiency low-resistance air filter material layer and bubble-point skeleton material layer. I...

Embodiment 3

[0069] Such as figure 2 A kind of bubble-point type air filter screen window shown, comprises window door frame 4, and the single-open bubble-point type air filter yarn is housed on the window door frame, and the single-open structure includes winding drum 5, push-pull bar 6 and bubble-point type air filter yarn 7. One end of the bubble-point air filter yarn is installed in the winding drum, and the other end is connected to a push-pull bar. The push-pull bar can stretch the bubble-point air filter yarn. The push-pull bar is magnetic, and the push-pull bar can be adsorbed by magnetic suction when closing On the suction strip on one side of the window and door frame, the suction strip is magnetic and is located on the opposite side of the winding drum.

[0070] Such as image 3 The bubble-point air filter yarn shown is composed of three layers of plane skeleton material layer, high-efficiency low-resistance air filter material layer and bubble-point skeleton material layer. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com