Horizontal well no-throttle straddle-type double-sealing single-grip fracturing process

A double-seal, single-card, and non-throttling technology, which is applied in the direction of production fluid, sealing/isolation, wellbore/well components, etc., can solve problems such as the influence of oil casing pressure difference, and achieve high pressure bearing index and high construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

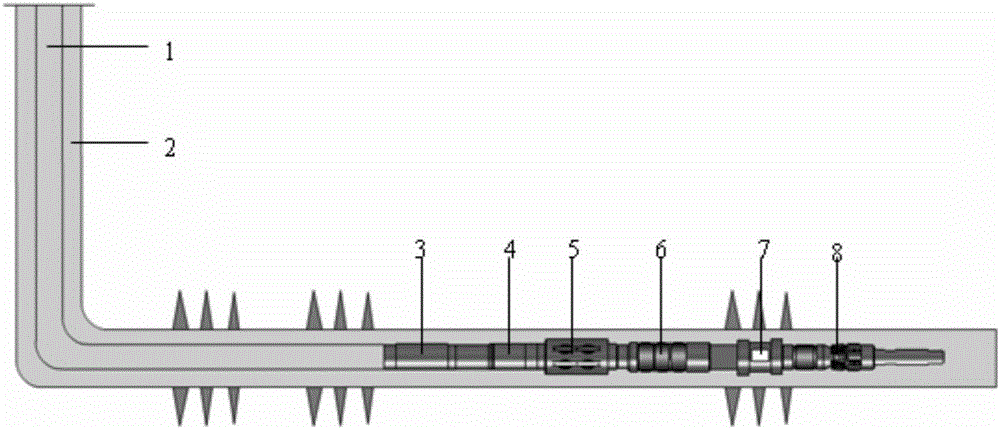

[0013] detailed description: Below in conjunction with accompanying drawing, the present invention is described further: the present invention is realized by following device: it is made of 1-oil pipe, 2-sleeve pipe, 3-pressure balance valve, 4-safety joint, 5-hydraulic anchor, 6 -Y111 packer, 7-large sand blaster, 8-Y211 packer; pressure balance valve 3, safety joint 4, hydraulic anchor 5, Y111 packer 6, large sand blaster 7 , the Y211 packer 8 is connected to the tubing 1 through threads in turn, and the above process is realized through the following steps:

[0014] a. First, connect the pressure balance valve 3, safety joint 4, hydraulic anchor 5, Y111 packer 6, large sand blaster 7, and Y211 packer 8 to the oil pipe 1 through threaded fasteners in turn, and run them into the casing 2 middle;

[0015] b. Secondly, after lowering the device into the pre-fracturing interval, lift the device up first, set the Y211 packer 8, and then observe the construction curve to check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com