Double-rotor wind power generation unit

A technology for wind turbines and wind turbines, which is applied to wind turbine combinations, wind turbines, wind turbines at right angles to the wind direction, etc. Improve power generation efficiency, strong wind resistance, and increase the effect of rotating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

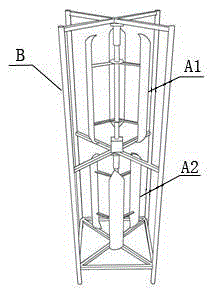

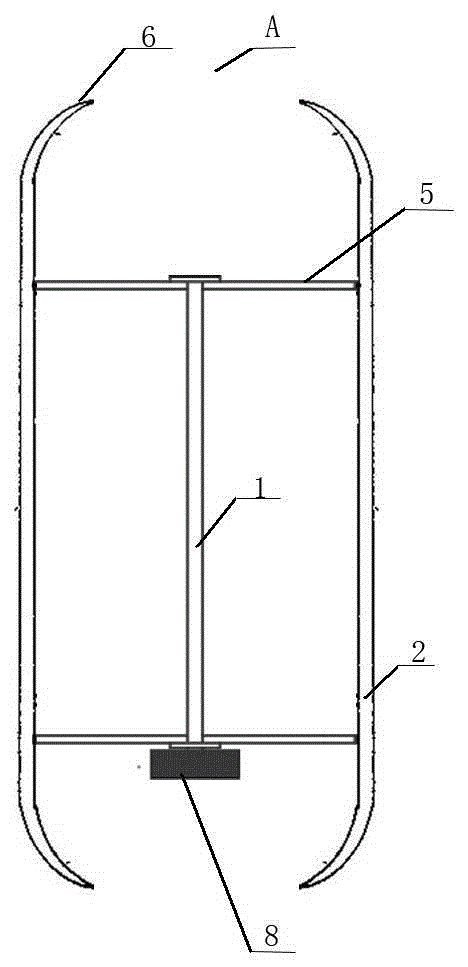

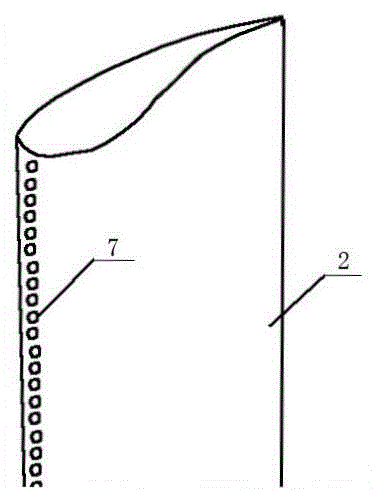

[0026] A double-rotor wind power generating set, comprising a generator 8, an upper wind rotor A1 arranged above the generator, and a lower wind rotor A2 arranged below the generator, and the generator 8, the upper wind rotor and the lower wind rotor are arranged on a cross-shaped frame perpendicular to the ground In B, the upper wind wheel is connected to the casing of the generator, and the lower wind wheel is connected to the intermediate shaft of the generator. The rotation directions of the upper wind wheel and the lower wind wheel are opposite; The vertical shaft 1 of the wind rotor is connected to the shaft of the generator 8, the vertical shaft of the wind rotor is perpendicular to the ground, and three blades 2 are installed on the vertical shaft 1; the blades are wing-shaped blades, and the leading edge a of the blade is provided with a turbulence prom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com