Injection oil return control method and device for air-conditioning system and air-conditioning system

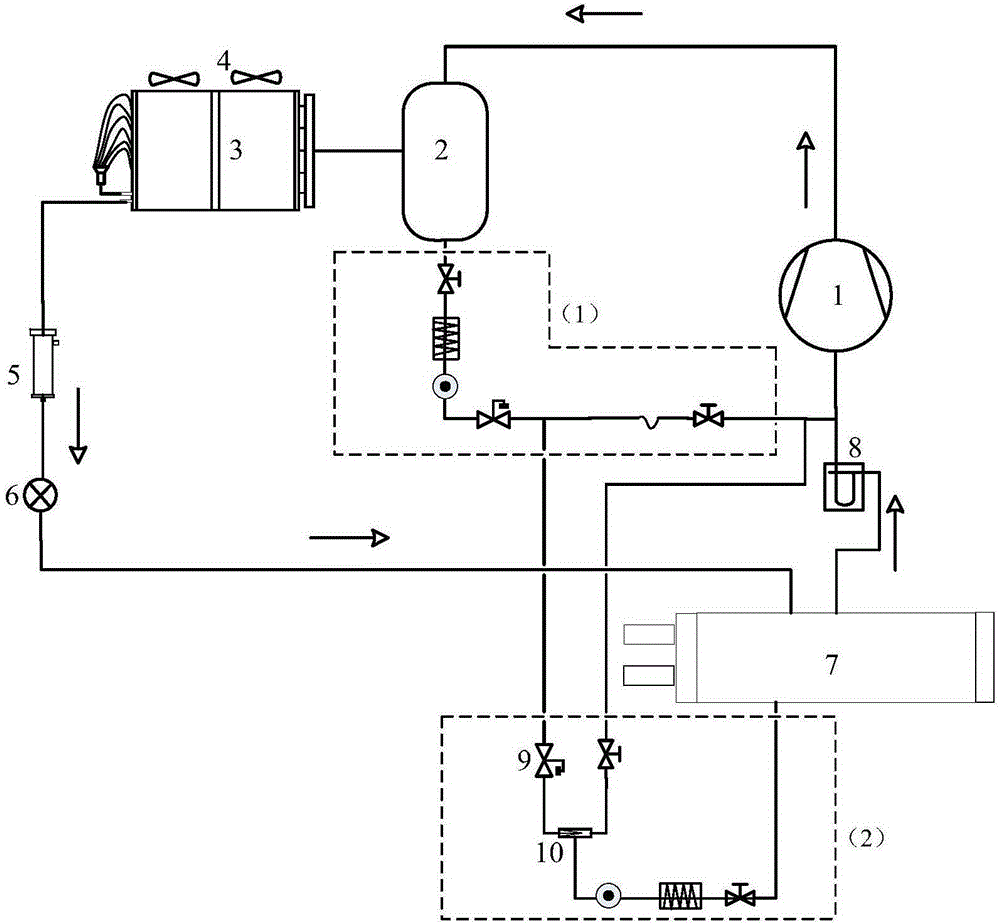

A technology for ejecting oil and air conditioning systems, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve problems such as low reliability and safety, burning compressors, etc., to improve safety, avoid oil shortage, The effect of preventing liquid shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

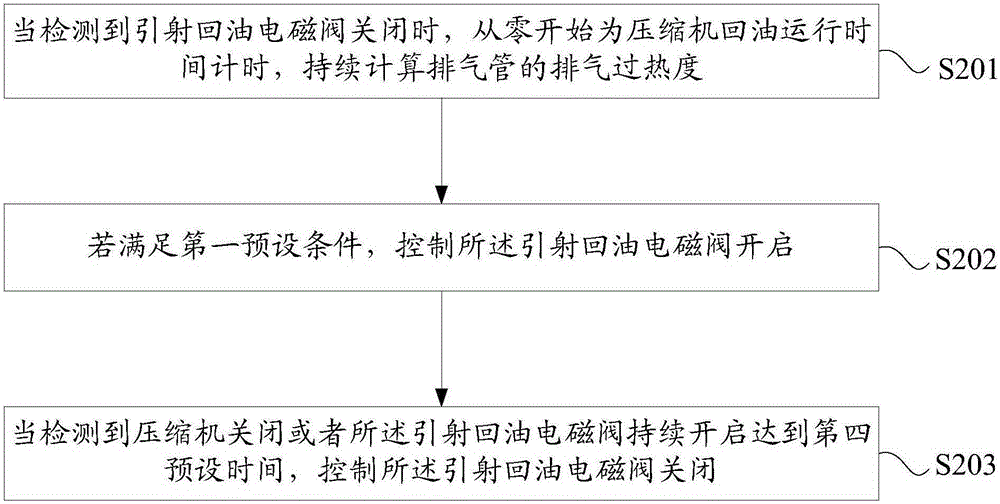

[0053] see figure 2 , figure 2 It is a flow chart of an air-conditioning system injection return control method provided by an embodiment of the present invention, and the technical solution provided by the embodiment of the present invention, the air-conditioning system includes a flooded shell-and-tube evaporator. like figure 2 As shown, the method includes:

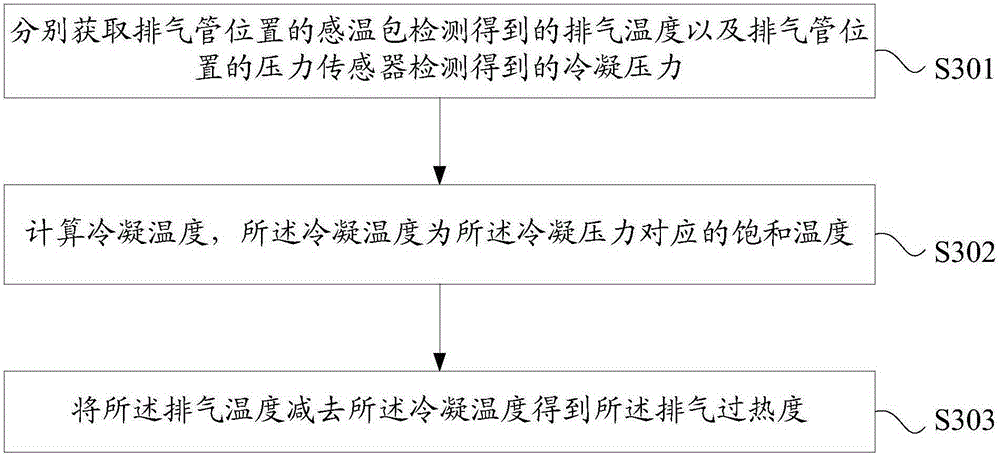

[0054] Step S201, when it is detected that the injection oil return solenoid valve is closed, count the oil return operation time of the compressor from zero, and continuously calculate the exhaust superheat of the exhaust pipe;

[0055] Specifically, when it is detected that the injection oil return electromagnetic valve is closed, the running time of the oil return of the compressor is counted from zero, and at the same time, the exhaust gas superheat of the exhaust pipe is continuously calculated.

[0056] Step S202, if the first preset condition is met, control the injector return solenoid valve to open;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com