Defrosting control method of refrigerator

A control method and technology for refrigerators, applied in defrosting, refrigerators, refrigeration components, etc., can solve problems such as heat waste, and achieve the effects of reducing energy consumption, reducing load, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

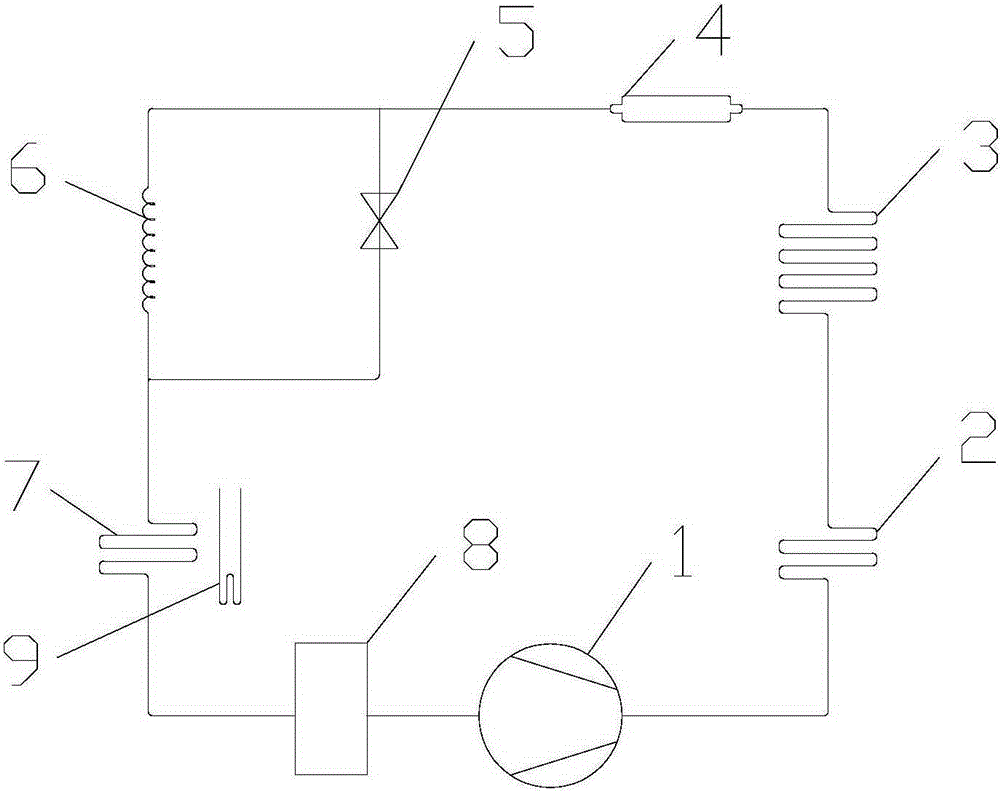

[0025] see figure 1 , the present invention provides a refrigerator, the refrigeration system of which includes a frequency conversion compressor 1, an anti-condensation pipe 2, a condenser 3, a filter 4, a capillary tube 6, an evaporator 7 and a liquid storage A defrosting heater 9 is arranged on the evaporator 8 and the evaporator 7, and a defrosting branch is connected across the two ends of the capillary 6, and a solenoid valve 5 is arranged on the defrosting branch.

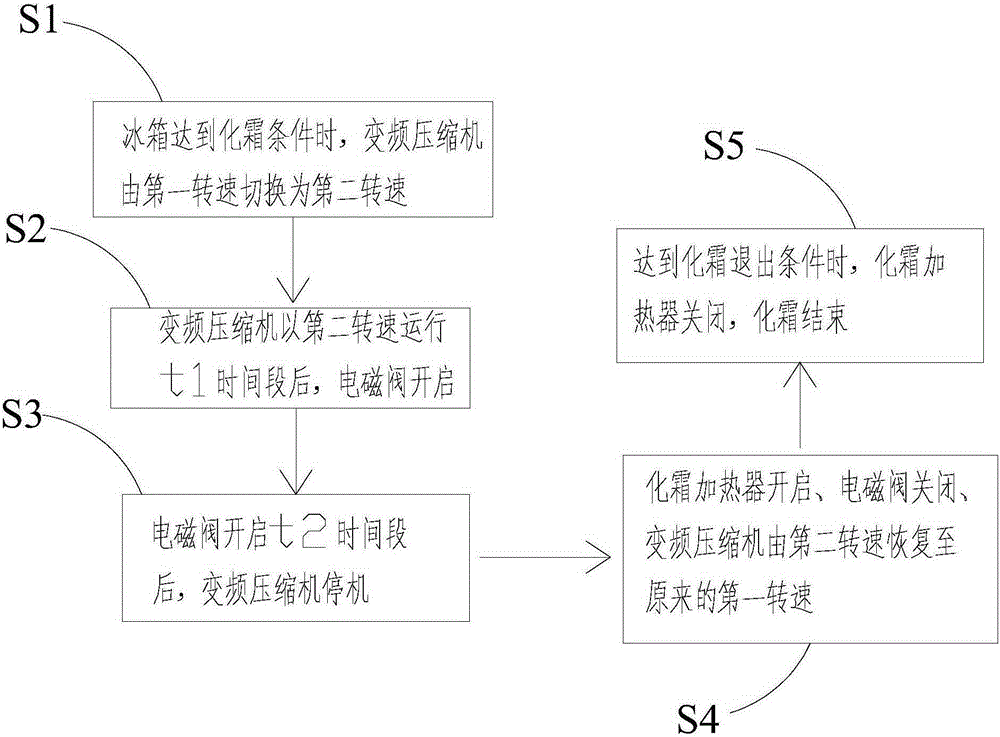

[0026] see figure 2 , the present invention also provides the defrosting control method of the refrigerator, comprising the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com