Split type tubular cooler for heat exchange of metal part quenching and tempering media

A tube cooler and tempering medium technology, applied in heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of affecting heat dissipation effect, inability to disassemble and clean, etc., and achieve the effect of clean and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

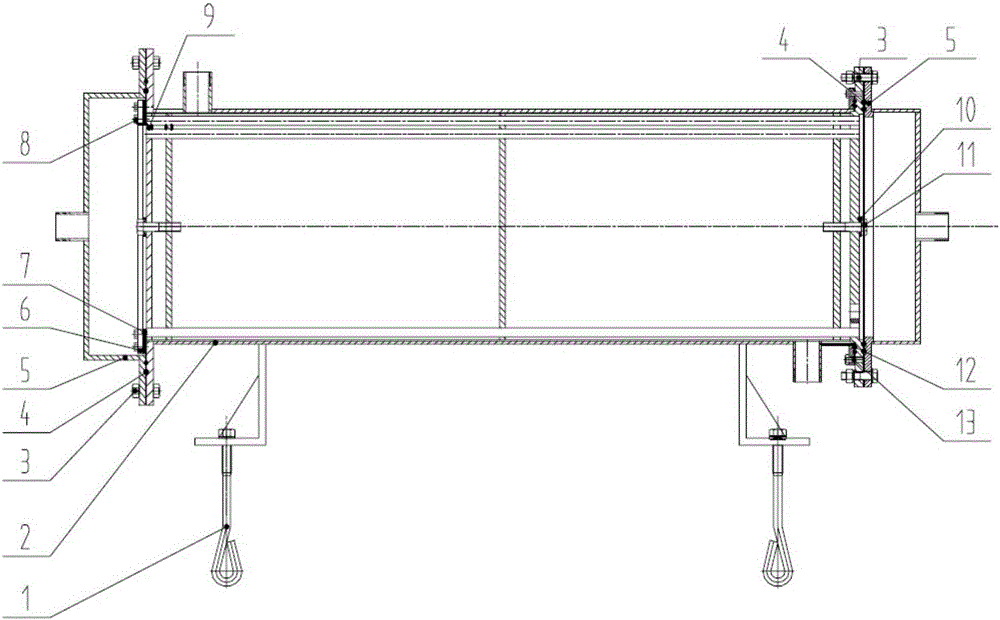

[0015] A split tube cooler for quenching and tempering medium heat exchange of metal parts, such as figure 1 As shown, including: anchor bolt 1, shell 2, bolt 3, O-shaped sealing ring 4, cover 5, gland 6, circular oil-resistant sealing ring 7, stainless steel bolt 8, exchange body 9, rectangular sealing ring 10 , Stainless steel bolt 11, 0-shaped oil-resistant sealing ring 12, bolt 13.

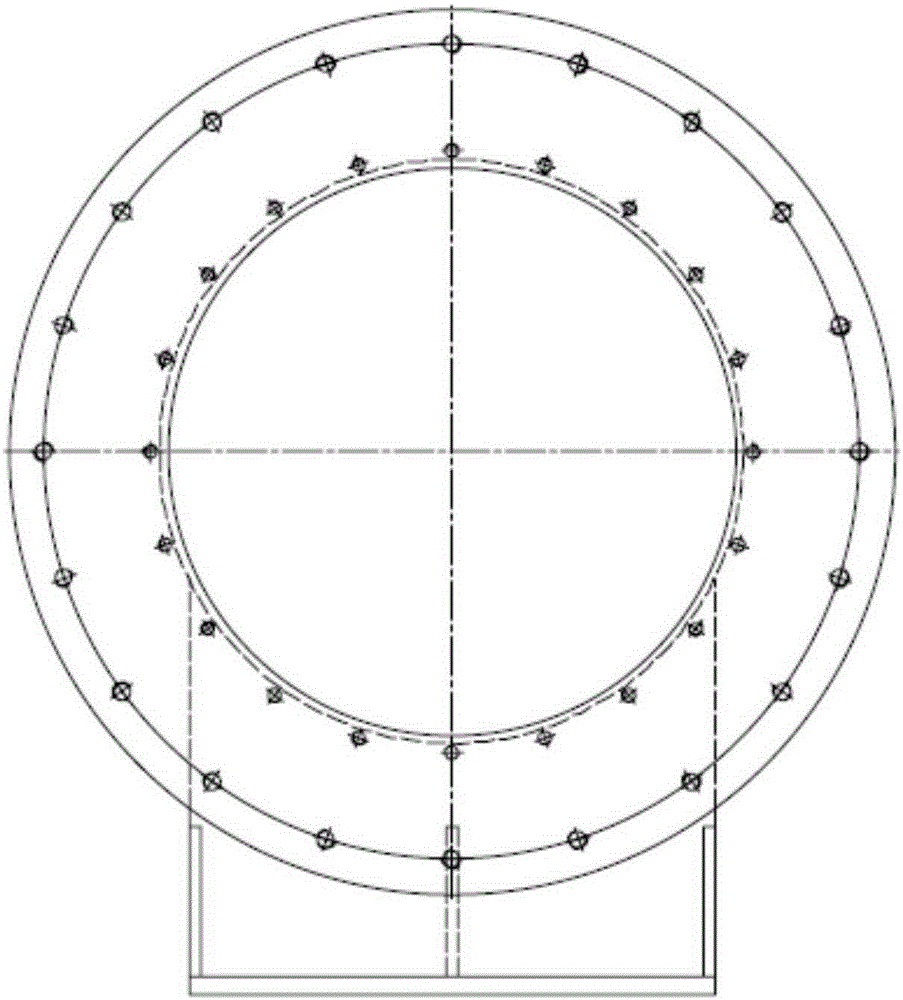

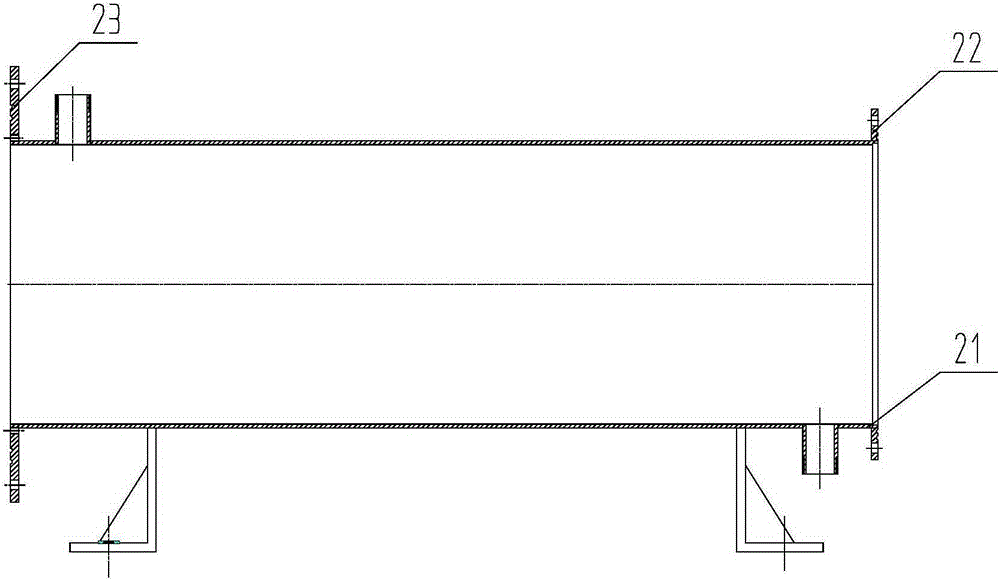

[0016] The shape and structure of the housing 2 are as figure 2 and image 3 As shown, it is made of seamless steel pipe, and a step hole 21 is processed in the inner diameter of one end, which is used for the installation and positioning of the exchange body 9; two large flanges 22 and 23 are welded at both ends, and two pipe joints are welded , as shown in the figure, there are two upper and lower ones, the upper pipe is connected to the water inlet pipe, and the lower pipe is connected to the water outlet pipe, according to the principle that the cold water in the same volume automatical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com