Segment test piece used for segment longitudinal seam anti-leakage performance test and manufacturing method thereof

A manufacturing method and segment technology, which are used in liquid/vacuum measurement for liquid tightness, earth-moving drilling, wellbore lining, etc. The correctness of the results needs to be further verified, complicated and other issues, to achieve good economic benefits, shorten the test time, and ensure the accuracy of the results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

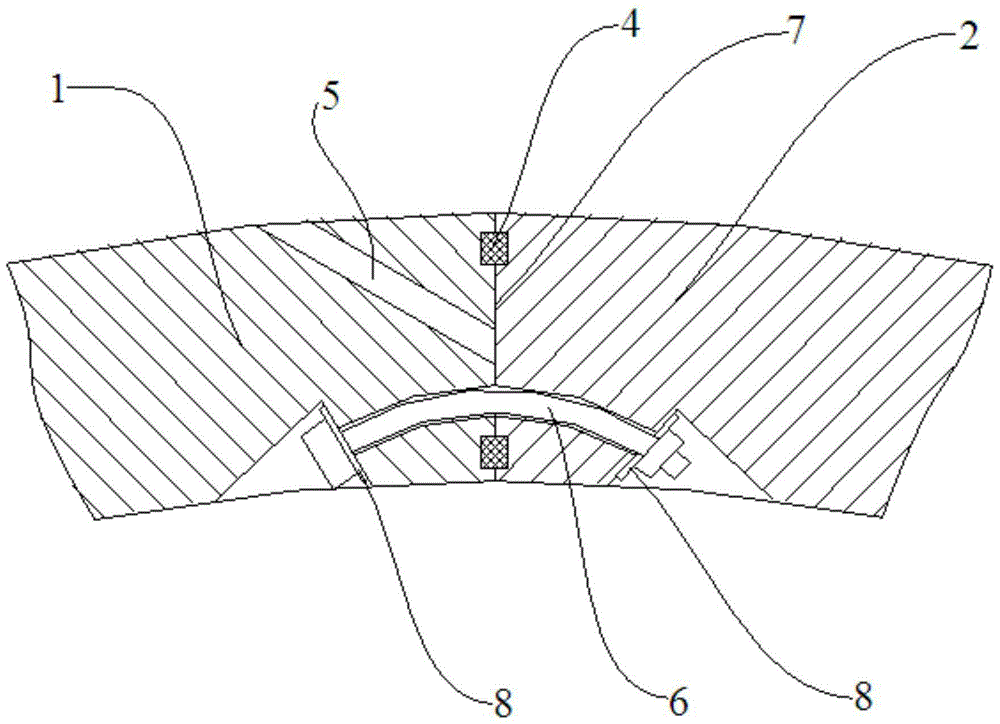

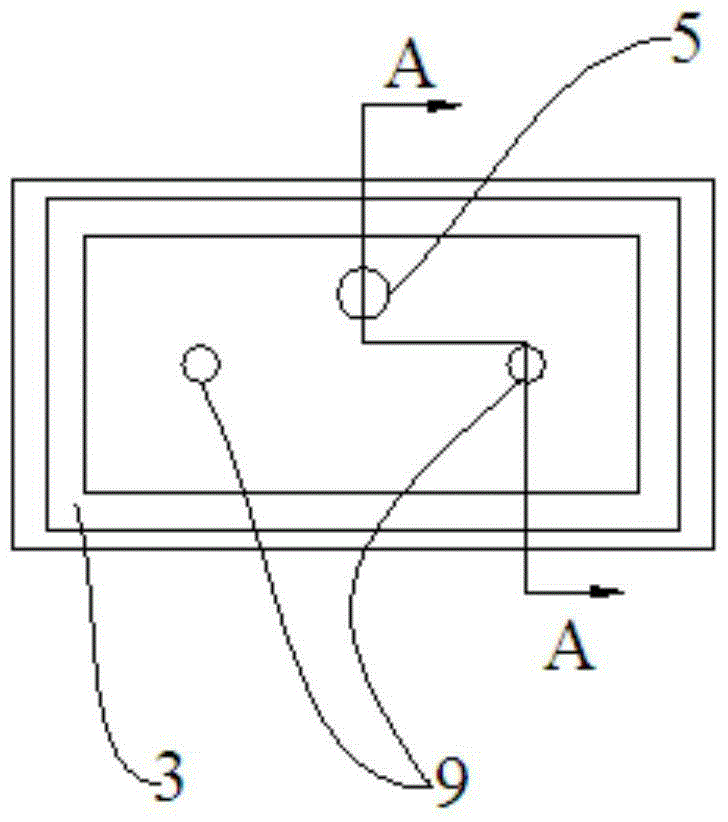

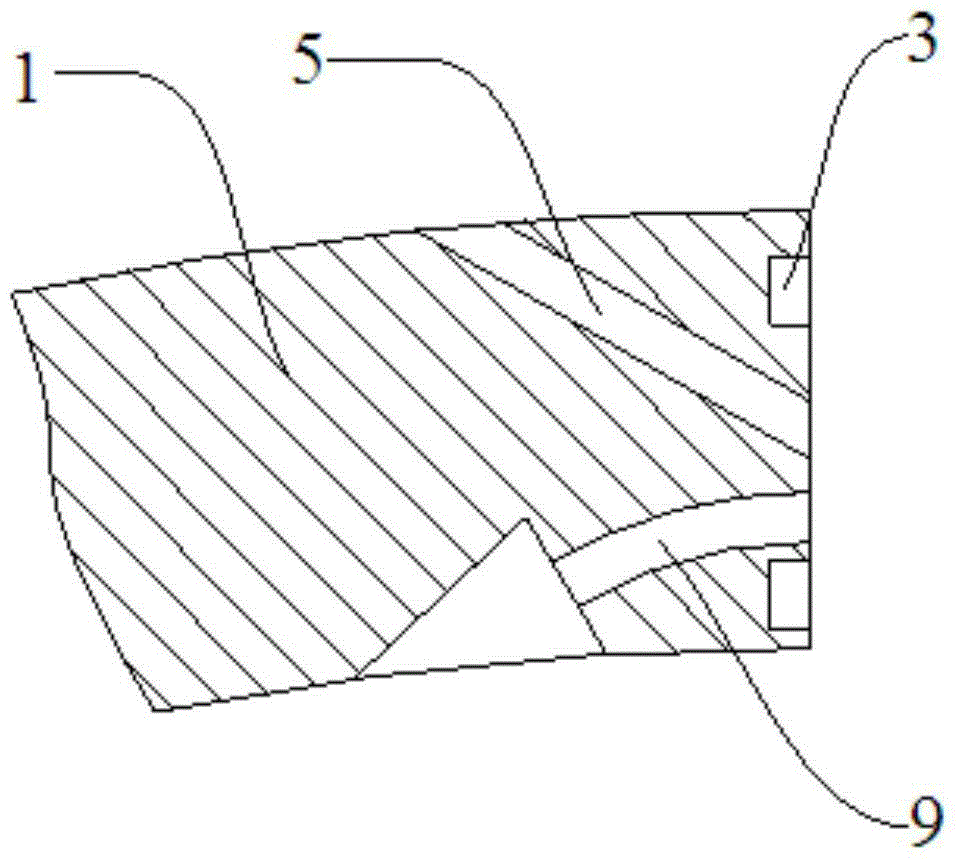

[0024] A segment test piece used for the anti-seepage performance test of segment longitudinal joints, such as Figure 1 to Figure 5 As shown, it includes an arc-shaped first segment 1 and an arc-shaped second segment 2. The opposite ends of the first segment 1 and the second segment 2 are both sealing surfaces. The first segment 1 and the second segment 2 are provided with a bolt hole 9 for passing through the connecting bolt 6, and the sealing surfaces of the first segment 1 and the second segment 2 are pressed against each other through the connecting bolt 6, and the first segment 1 and the second segment 2 are provided with a frame-shaped groove 3 on the sealing surface, and an elastic gasket 4 with end-to-end closed connection is embedded in the frame-shaped groove 3. A water injection channel 5 is also provided on the first segment 1. The water injection channel 5 One end of the water injection channel 5 is located on the upper arc surface of the first segment 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com