Vertical surface round slideway four-side adjustable styrene butadiene rubber pressure plate

A round and pressing plate technology, applied in the field of four-sided adjustable styrene-butadiene rubber pressing plate of the circular slide on the facade, can solve the problems of uneven force on the surrounding, unable to continuously change different widths, and taking a long time to achieve. The personal safety is more guaranteed, the cost of test consumables is saved, and the work efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

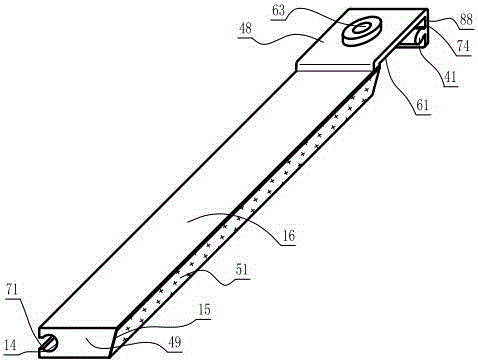

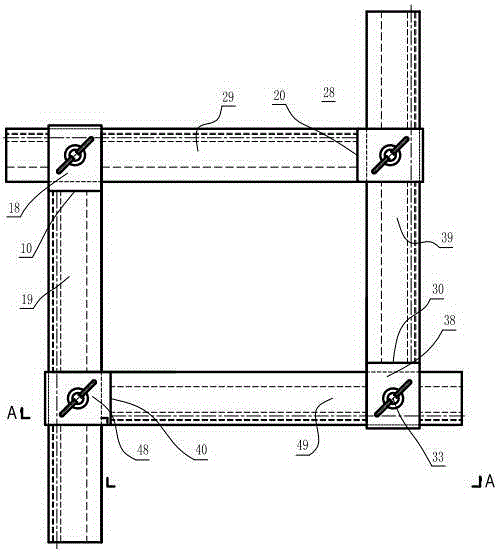

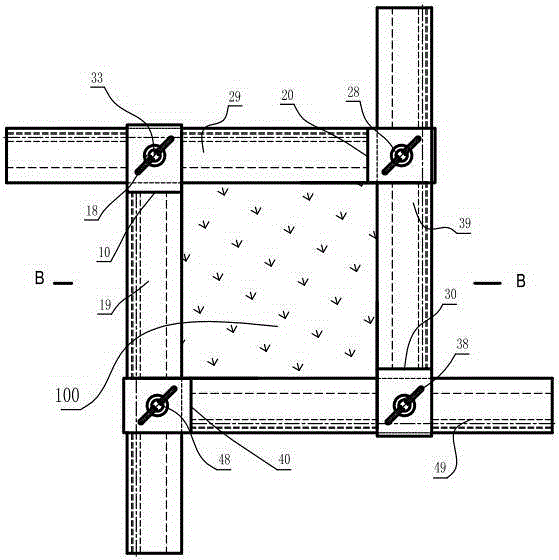

[0036] figure 1 , figure 2 , Figure 4 , Image 6 , Figure 7 with Figure 8 middle:

[0037]The four-sided adjustable styrene-butadiene rubber platen of the vertical circular slideway includes four first platen 10, second platen 20, third platen 30 and fourth platen 40 with the same structural size, each platen consists of a clamping part and a slide The first pressing plate 10 is composed of the first clamping portion 19 and the first sliding portion 18, the second pressing plate 20 is composed of the second clamping portion 29 and the second sliding portion 28, and the third pressing plate 30 is composed of a third clamping part 39 and a third sliding part 38, and the fourth platen 40 is composed of a fourth clamping part 49 and a fourth sliding part 48; as an improvement:

[0038] The sliding part includes a sliding horizontal plate 61 and a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com