Slump cone and method for testing working performance of self-compacting concrete

A technology of self-compacting concrete and slump, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problems of affecting project quality, time-consuming, poor performance compounding, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

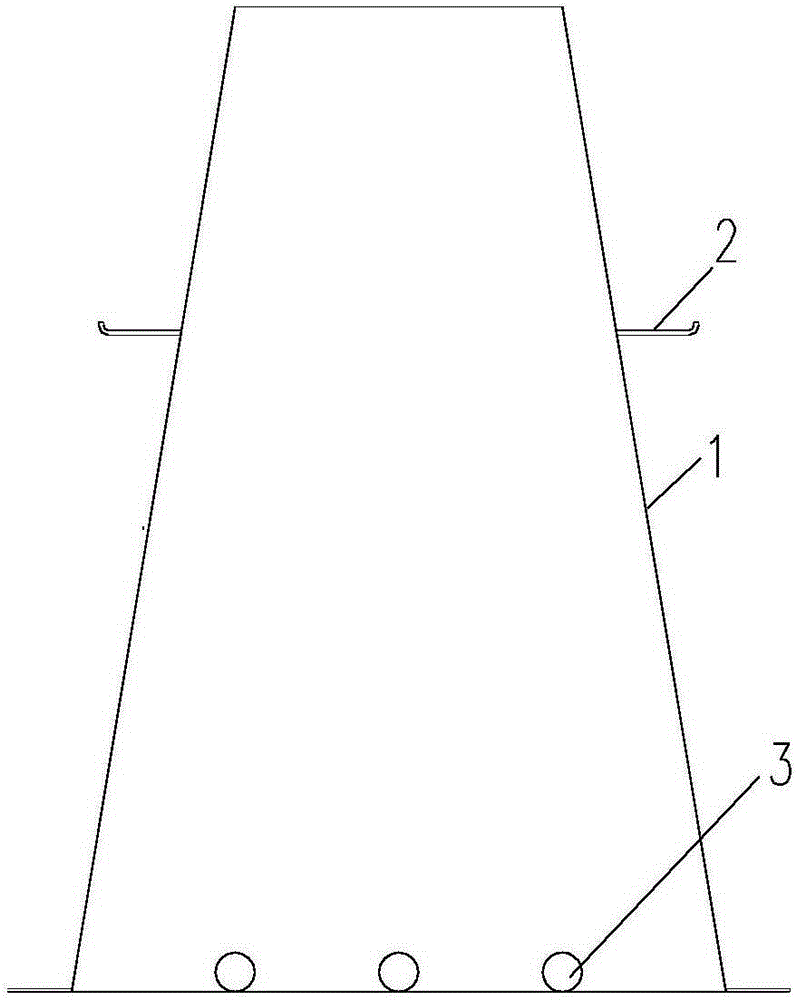

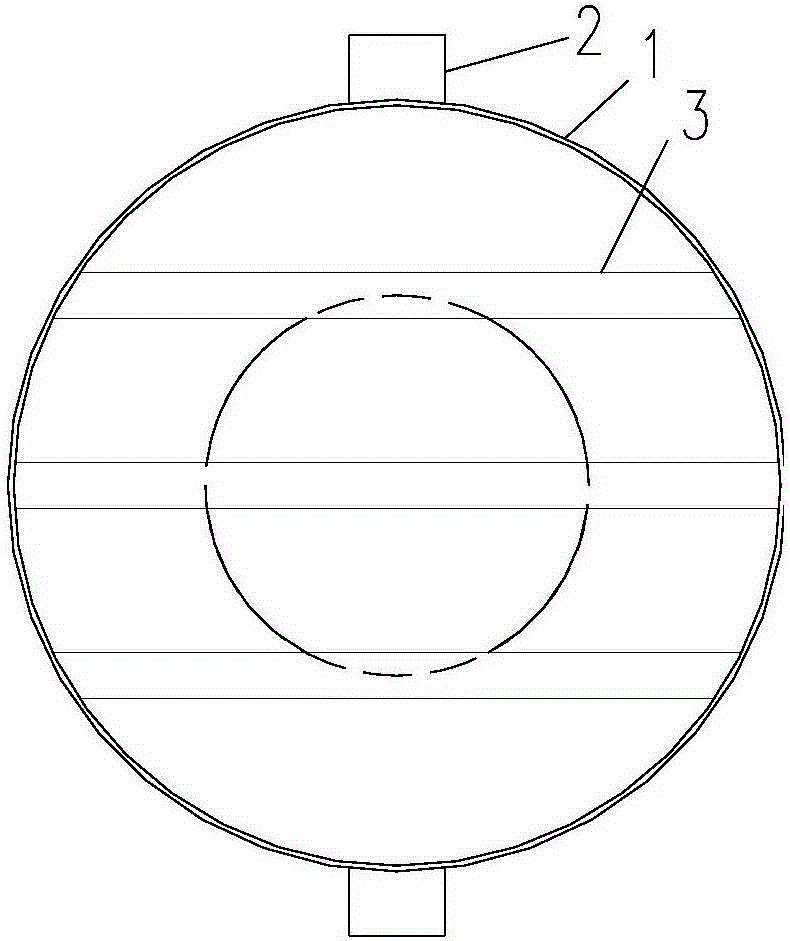

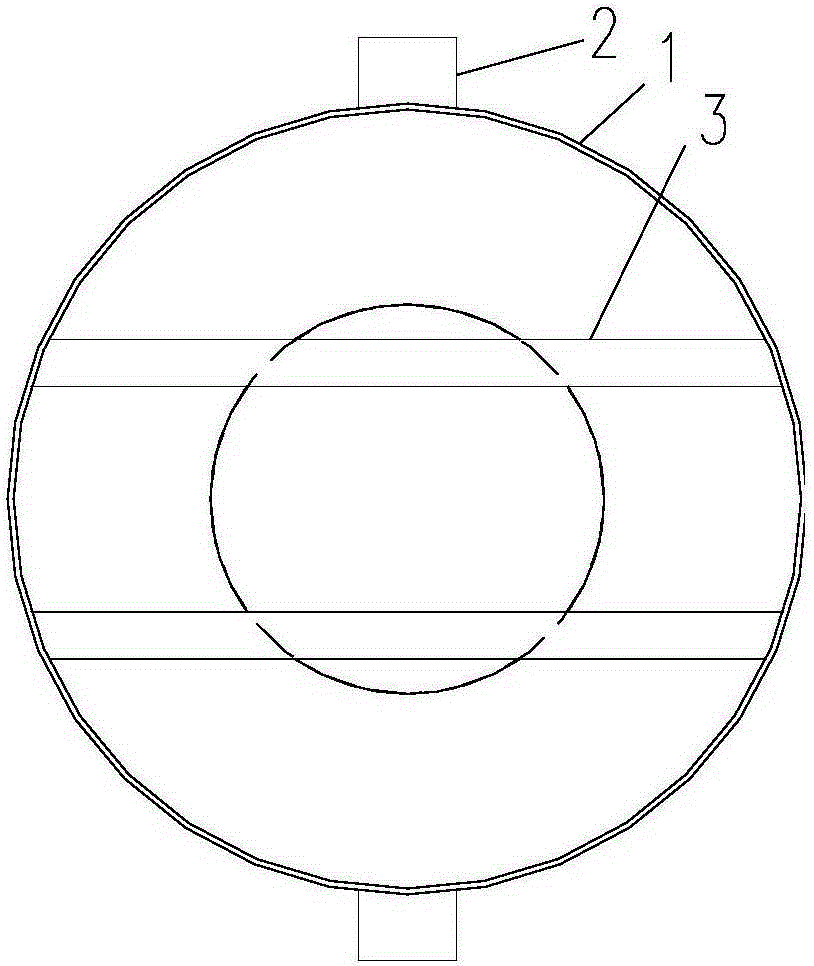

[0021] exist figure 1 In the schematic diagram of the slump cylinder shown, the slump cylinder 1 is a tower-shaped cylinder with a thin upper part and a thicker lower part. Two opposite handles 2 are arranged above the two sides of the outer wall of the cylinder body, and the steel bar grid 3 is welded on the slump At the bottom of the slump cylinder, the lower skin of the reinforcement grid is flush with the bottom of the slump cylinder, and the longitudinal ribs at both ends of the reinforcement section of the reinforcement grid are at the same height and arranged at equal intervals. figure 2 It is a ribbed steel bar with a diameter of 12mm, and the net spacing of the steel bars is 41mm, which is suitable for testing the workability of self-compacting concrete aggregates with a maximum particle size of 20mm; image 3 The net spacing of steel bars with a diameter of 12mm is 59mm, which is suitable for testing the workability of self-compacting concrete aggregates with a maxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap