Laser device

A laser device and laser beam technology, applied in the laser field, can solve problems such as laser self-excited oscillation and device damage, achieve high output energy, avoid laser self-excited oscillation problems, and have good beam shaping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

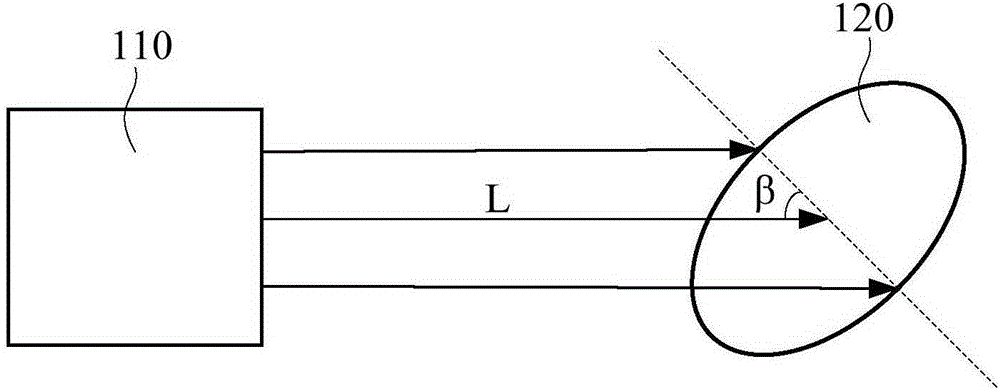

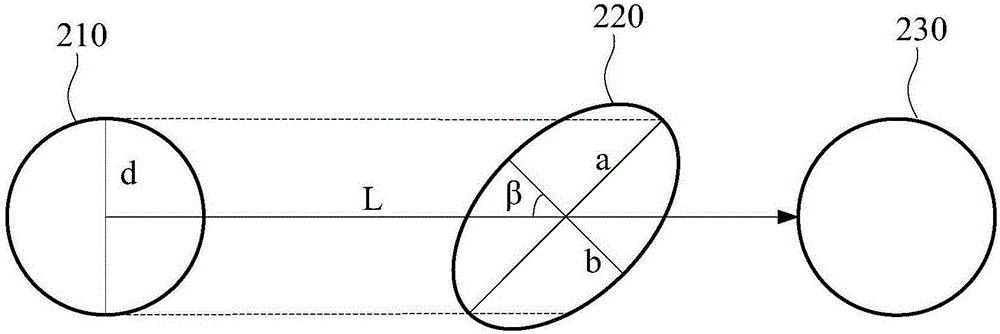

[0015] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of an embodiment of the laser device in the embodiment of the present invention; figure 2 yes figure 1 Projection plot of the spot in the illustrated embodiment.

[0016] Such as figure 1 As shown, the laser device includes a laser light source 110 and a soft edge diaphragm 120 . The laser device may be a laser (such as a laser amplifier), or other laser light-emitting devices. The laser light source 110 may include a light-emitting device composed of a laser diode array, or other high-power light-emitting devices. The soft-edge diaphragm 120 is elliptical, and is used to homogenize the laser beam emitted by the laser light source 110, and the laser beam L emitted by the laser light source 110 is incident on the soft-edge diaphragm 120 at an incident angle of β, and 0 degree<β <90 degrees.

[0017] Such as figure 2 As shown, the laser light source is used to emit a laser beam L with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com