Solar energy photovoltaic assembly taping type bonding sealing structure

A solar photovoltaic, bonding and sealing technology, applied in the field of solar energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

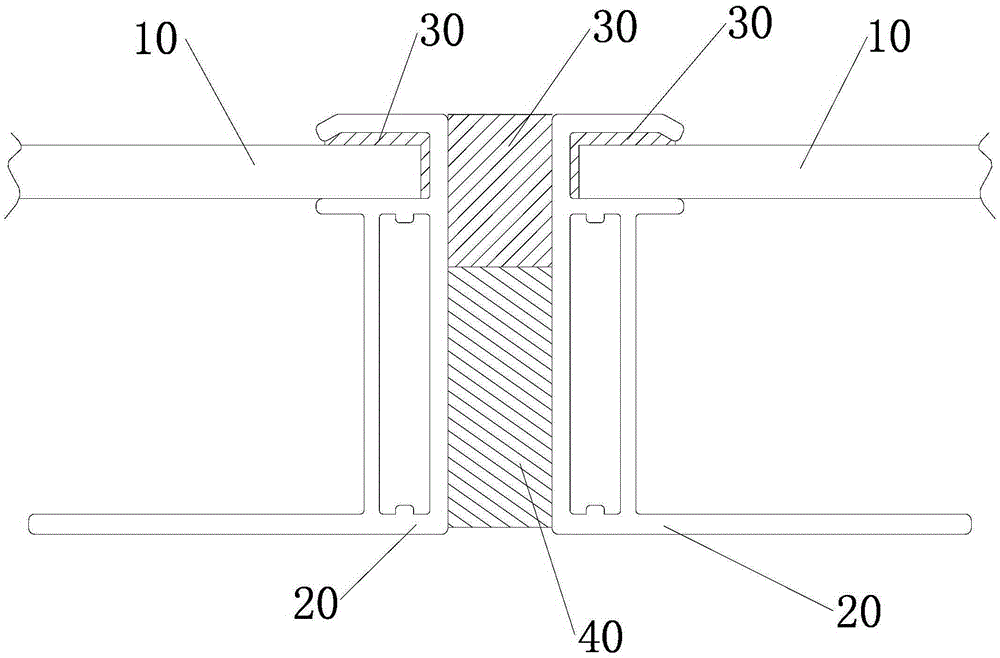

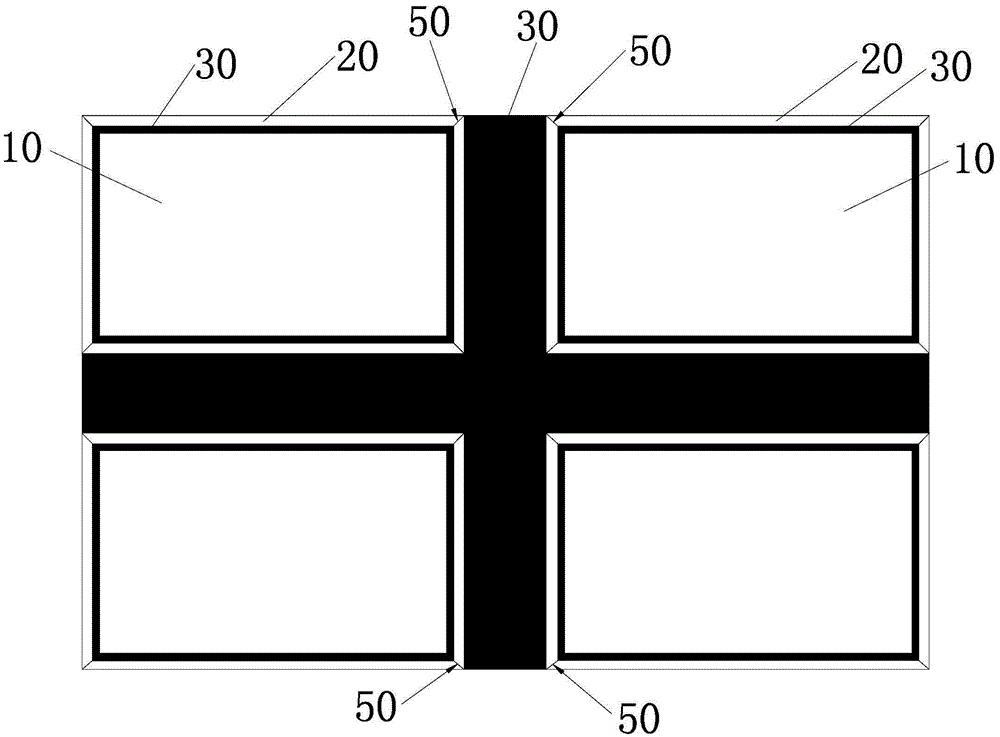

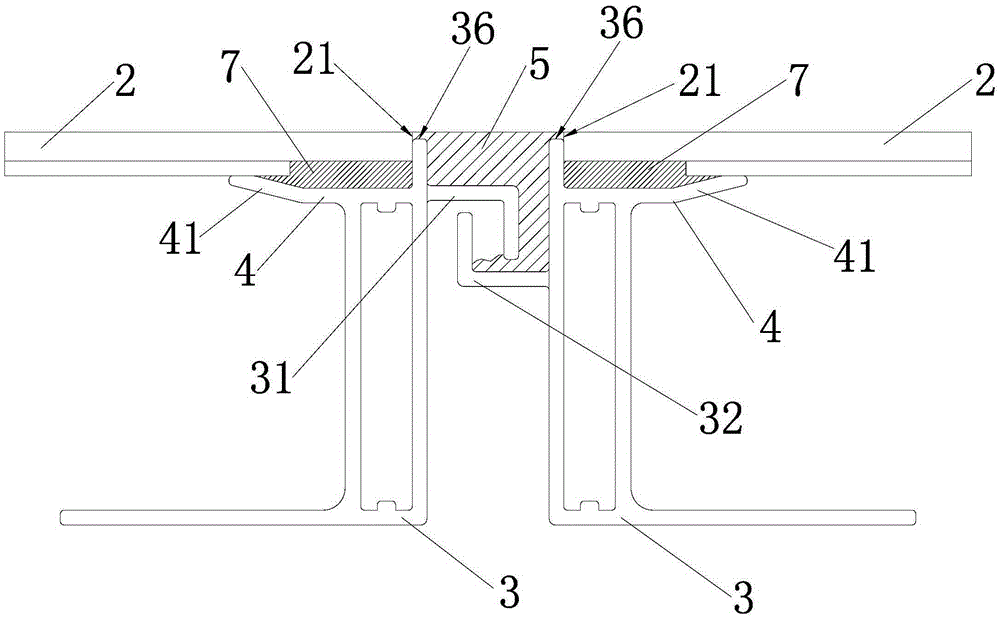

[0018] A kind of adhesive sealing structure of solar photovoltaic modules, such as Figures 3 to 6 As shown, it is spliced by several pieces of solar photovoltaic modules 1, and each solar photovoltaic module 1 includes a square solar panel assembly 2 and four frame profiles 3 arranged on the four sides of the solar panel assembly 2. The outer walls of the four frame profiles 3 are provided with splicing wings for splicing adjacent solar photovoltaic modules, and the upper ends of the inner walls of the four frame profiles are provided with a support plate 4 for supporting the solar panel assembly 2. When the solar panel assembly is used, a sufficient amount of solar panel fixing glue 7 will be filled on the top of the supporting plate 4 first, and then the lower surface of the solar panel assembly 2 will be pasted and fixed on the supporting plate 4. After installation, the solar panel assembly 2 The upper surface 21 of the upper surface 21 is higher than the top 36 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com