Motor shock pad

A shock-absorbing pad and cylinder technology, applied in the field of motor shock-absorbing equipment, can solve problems such as large vibration, large equipment noise, resonance, etc., and achieve the effect of reducing vibration and avoiding resonance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

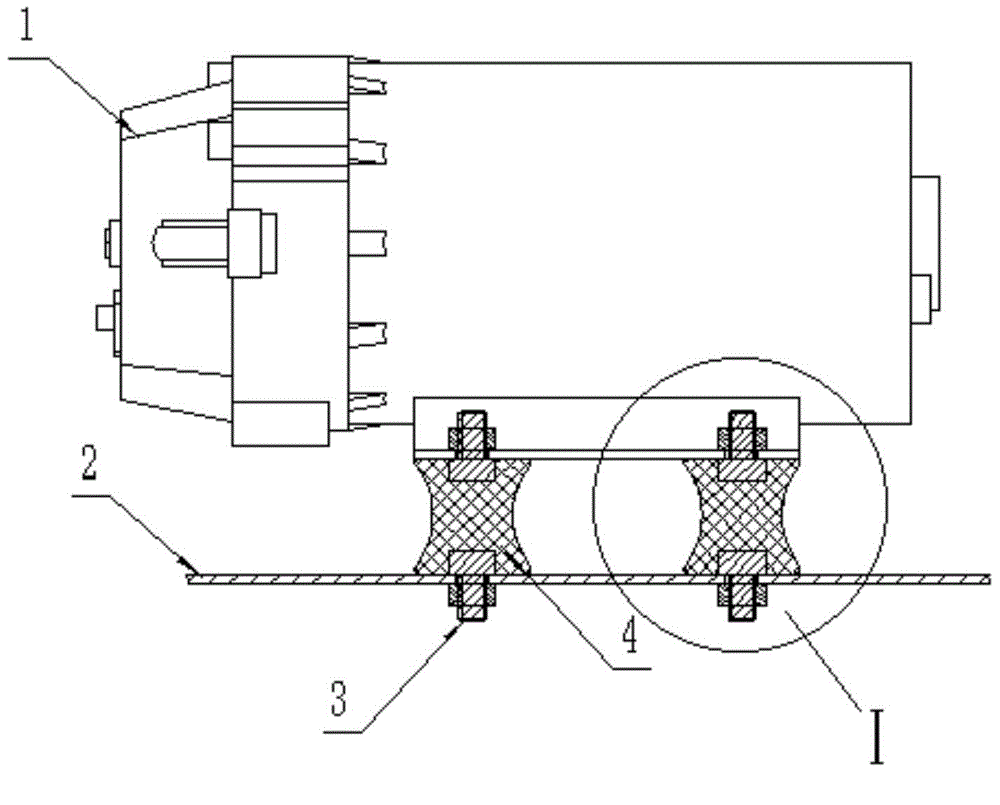

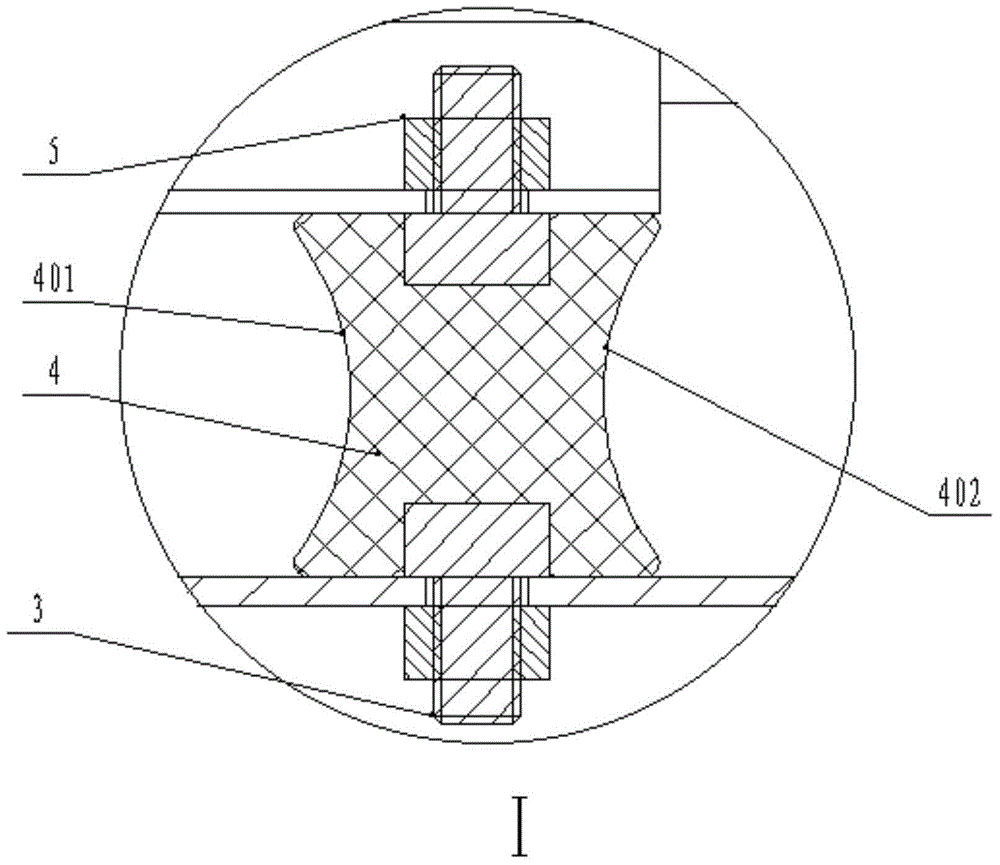

[0021] Motor shock absorbers, such as image 3 As shown, including the waist-reducing cylinder 4, the material of the waist-reducing cylinder 4 is soft PVC, wherein the plasticizer content is 40%. The material of the plasticizer is aliphatic carboxylate. Both upper and lower ends of the waist-receiving cylinder 4 are fixedly provided with screw rods 3 . A nut 5 is also provided on the screw rod 3 .

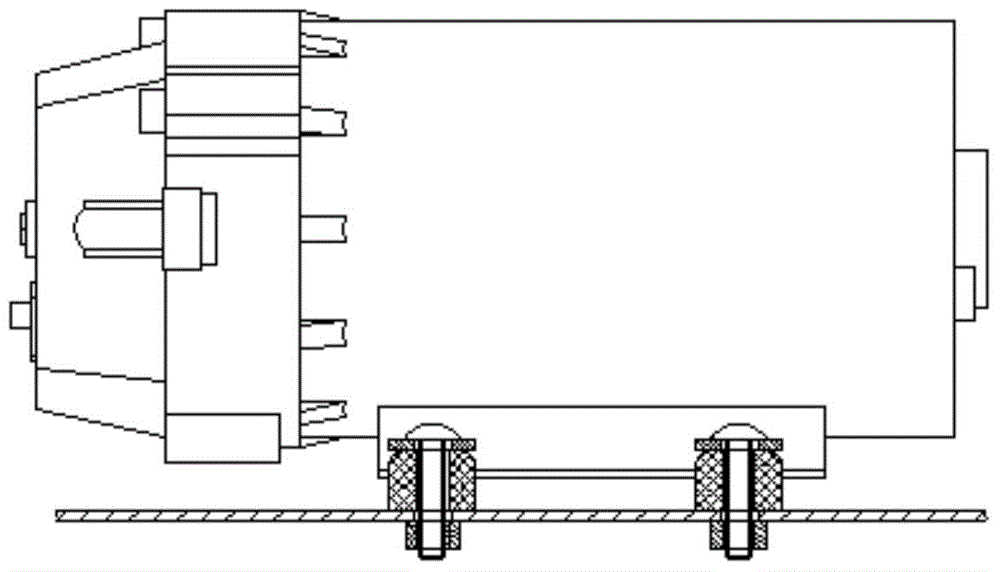

[0022] The water purifier with the shock and noise reduction device is placed under the motor foot of the motor 1, such as figure 2 As shown, the screw rod 3 at the upper end of the waist cylinder 4 passes through the motor pin and is tightened with the nut 5, and the screw rod 3 at the lower end of the waist cylinder 4 passes through the base 2 and is also tightened with the nut 5.

[0023] The outer contour line of waist-receiving cylinder 4 vertical sections comprises left contour line 401 and right contour line 402, and left contour line 401 and right contour line 402 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com