How to make Segmented Gold Fingers

A production method and golden finger technology, which is applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of gold seepage in segmented areas, inconsistent gold seepage degree, inability to completely solve gold seepage, etc., to ensure consistency, Improve processing speed and avoid the effect of unstable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

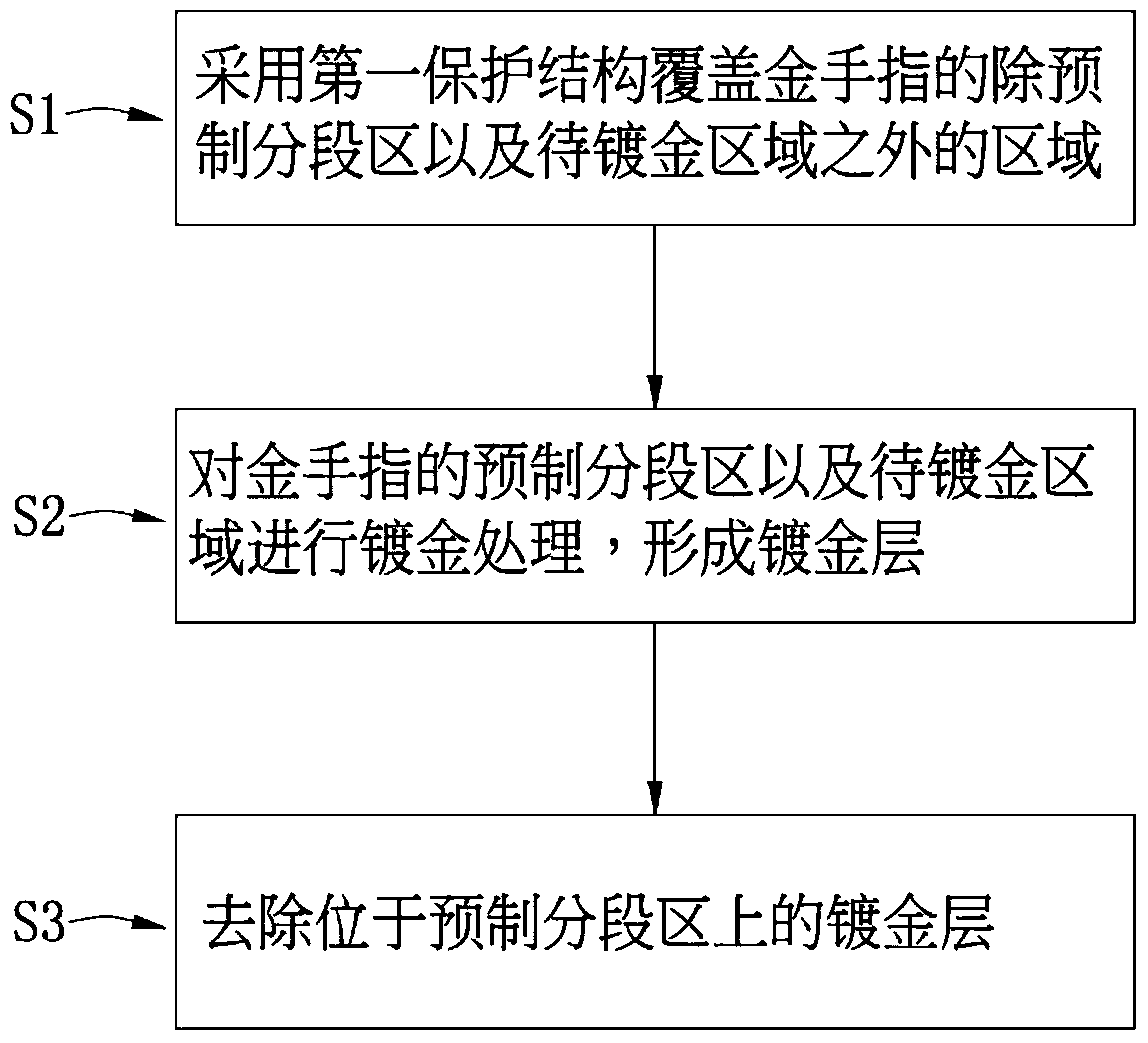

[0043] Such as figure 1 As shown, it is a flow chart of a method for making a segmented golden finger provided by this embodiment, which mainly includes the following steps:

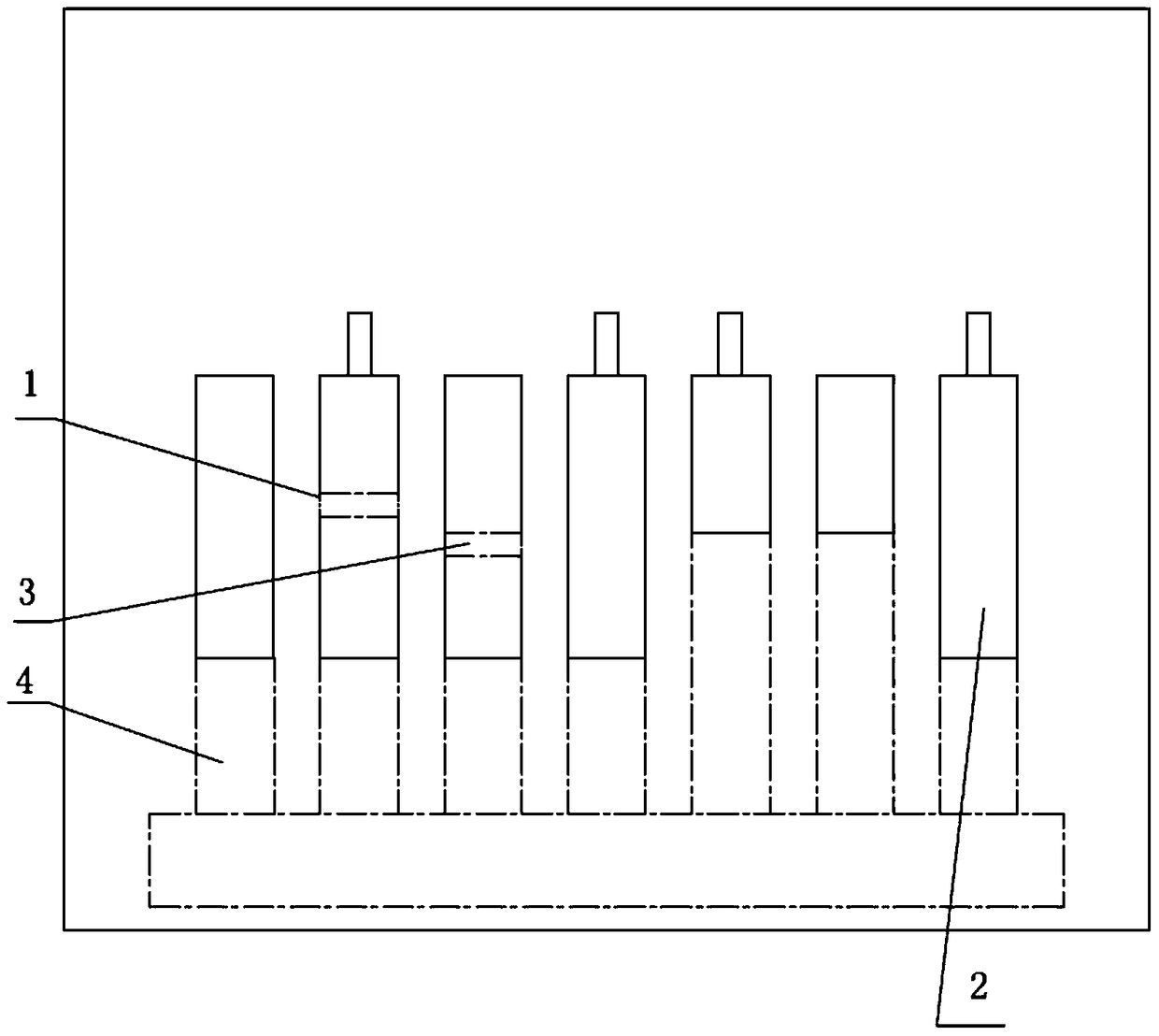

[0044] S1: Use the first protective structure 5 to cover the area of the gold finger (not shown in the figure) except the prefabricated segment area 1 and the area to be gold-plated 2, such as image 3 shown;

[0045] S2: Carry out gold-plating treatment on the prefabricated section area 1 of the gold finger and the area 2 to be gold-plated to form a gold-plated layer 6;

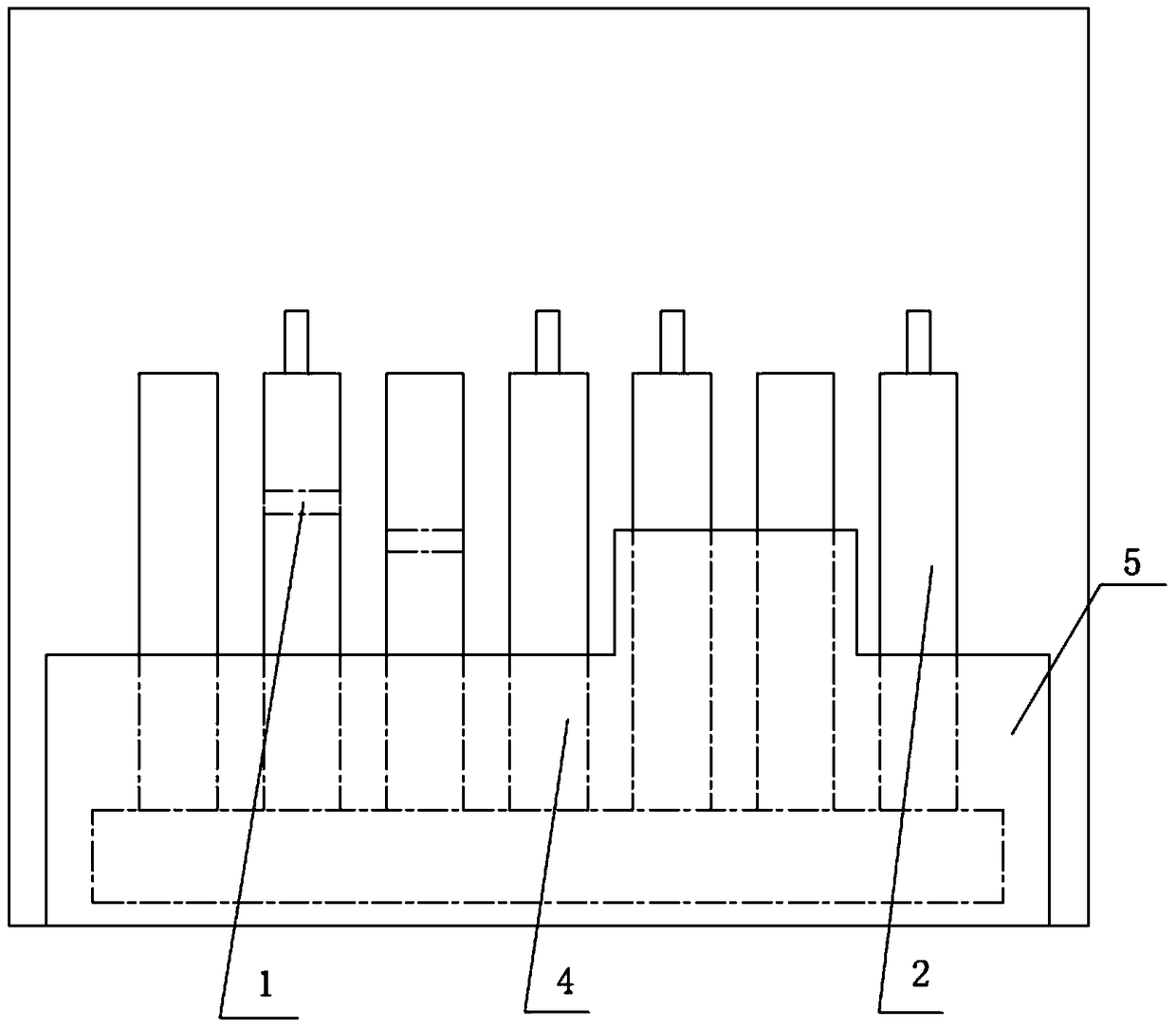

[0046] S3: remove the gold-plated layer 6 located on the prefabricated segment area 1, such as Figure 4 and Figure 5 shown.

[0047]The manufacturing method of the above-mentioned segment gold finger adopts the first protective structure 5 to cover the area of the gold finger except the prefabricated segment area 1 and the area to be gold-plated 2, which makes the pre-fabricated segment The section area can also be plated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com