MBL driving circuit-based LED bulb

A technology for LED light bulbs and driving circuits, applied in electric light sources, electrical components, electroluminescent light sources, etc., can solve the problems of chips and capacitors, inductance sensitive to temperature rise, circuit capacitor power factor, power supply noise and electromagnetic compatibility, etc. , to achieve the effect of improving circuit safety, saving materials and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

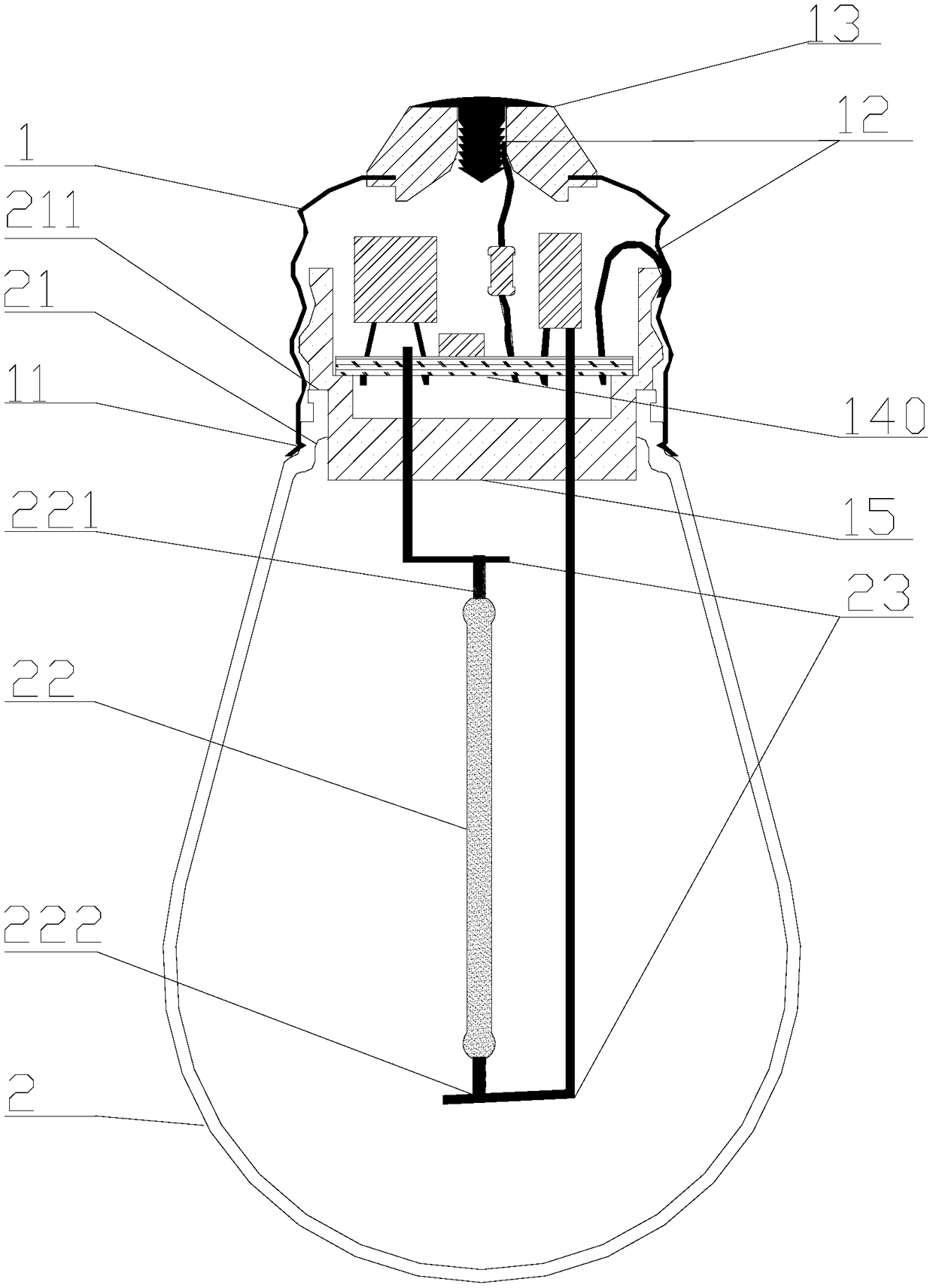

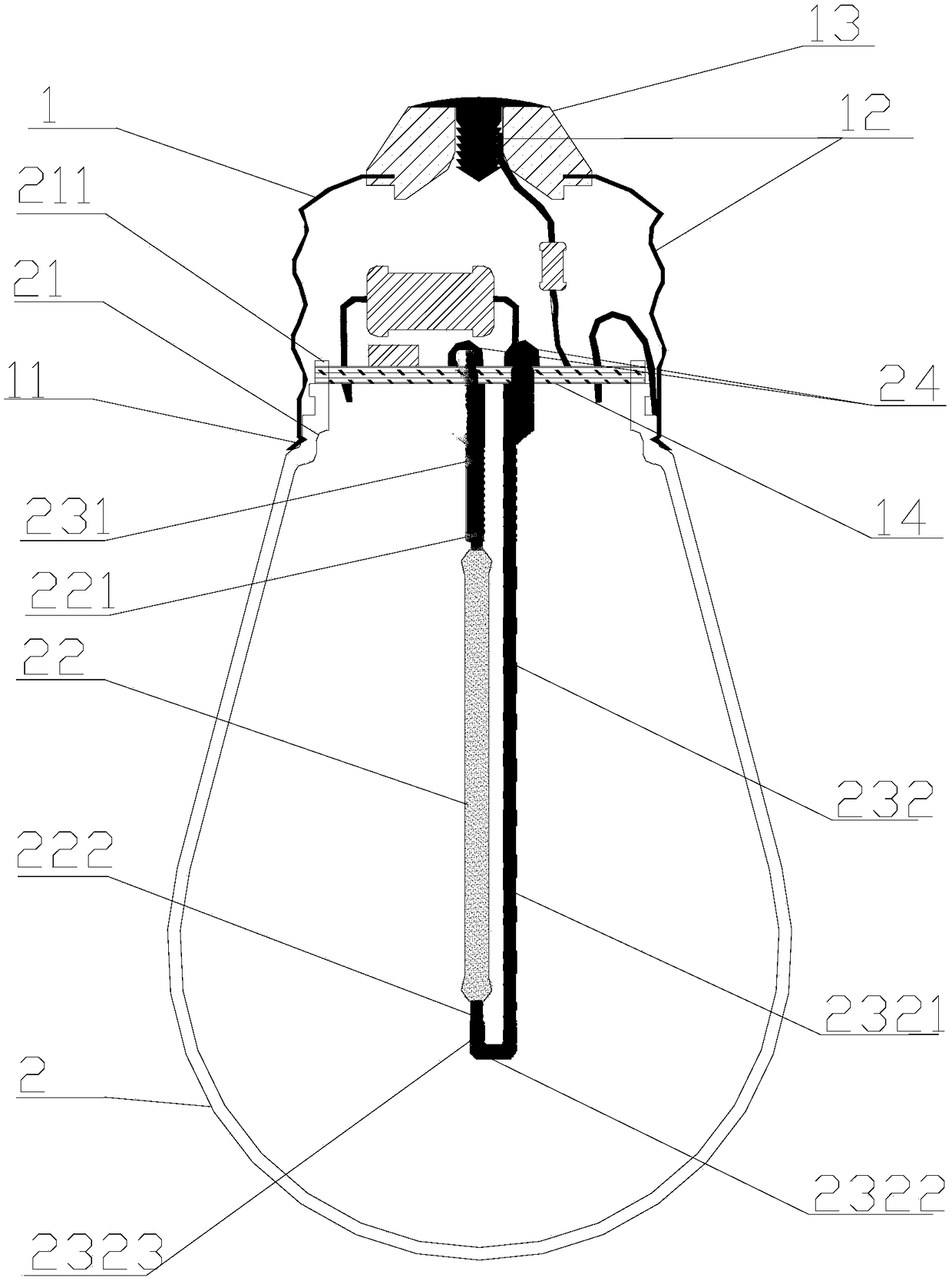

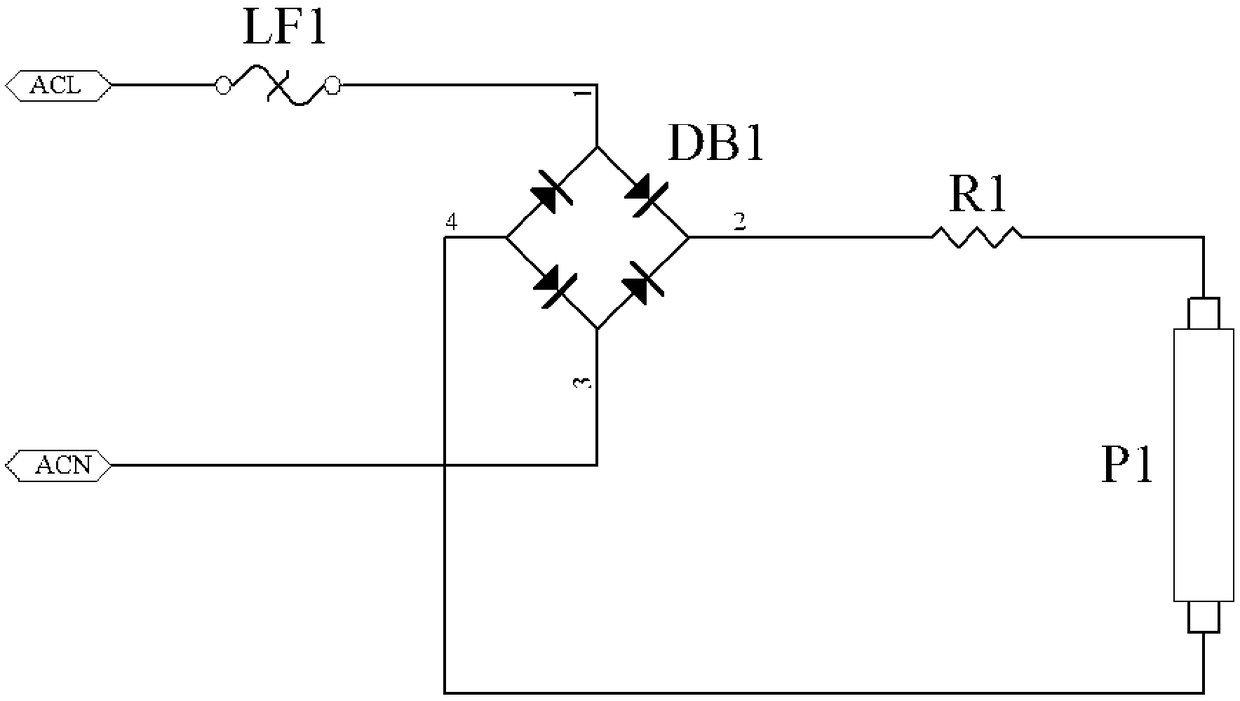

[0028] refer to figure 2 , image 3 with Figure 4 , an LED light bulb based on an MBL drive circuit in the present invention, comprising a lamp cap 1, a plastic bulb 2 and an MBL drive circuit assembly 14, the lamp cap 1 is riveted to the plastic bulb 2, and the MBL drive circuit assembly 14 is installed and fixed In the inner cavity of the lamp holder 1, the MBL drive circuit assembly 14 includes a wire-wound safety resistor LF1, a rectifier bridge DB1, a metal oxide film resistor R1 and an LED illuminant P1, and the rectifier bridge DB1 is a full-bridge rectifier bridge stack, so The rectifier bridge DB1 includes pin 1, pin 2, pin 3 and pin 4, the two input ends of the rectifier bridge DB1 are respectively pin 1 and pin 3, and the pin 1 is a positive input end, The live wire of the mains is connected in series with the wire-wound insurance resistor LF1 with surge suppression function connected to pin 1, the pin 3 is connected to the neutral wire of the mains, the pin 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance range | aaaaa | aaaaa |

| Temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com