Airless tire and method for manufacturing same

A technology for non-pneumatic tires and hubs, applied in the direction of non-pneumatic tires, tire parts, tires, etc., can solve problems such as damage and deterioration of tire durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail.

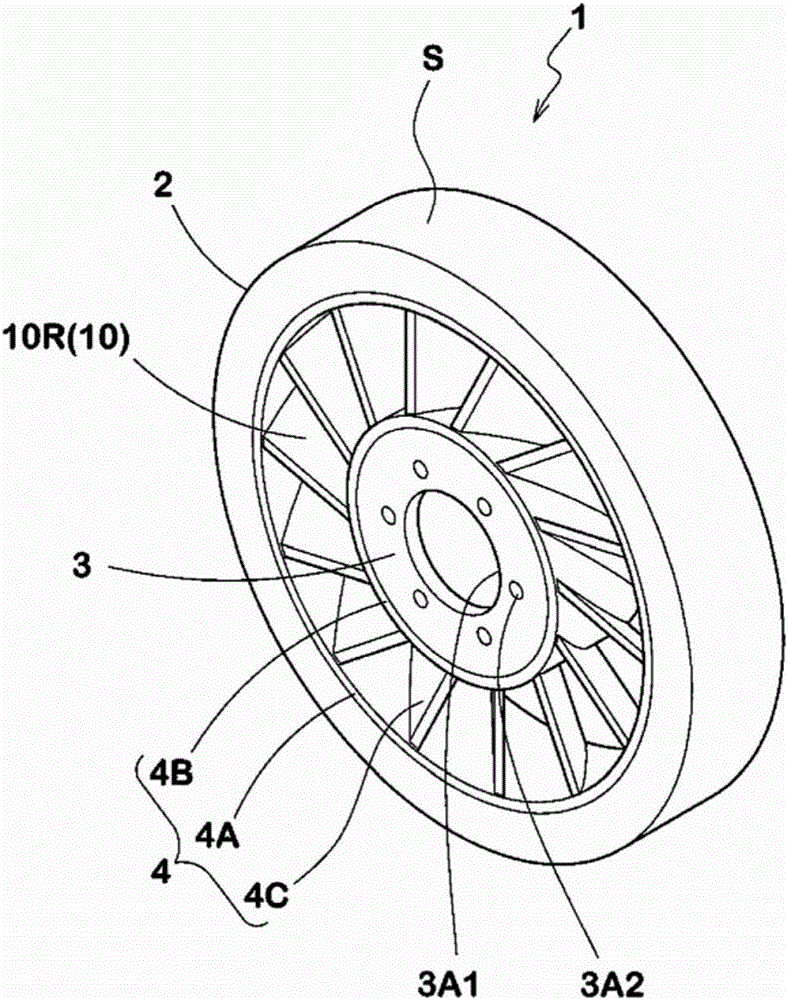

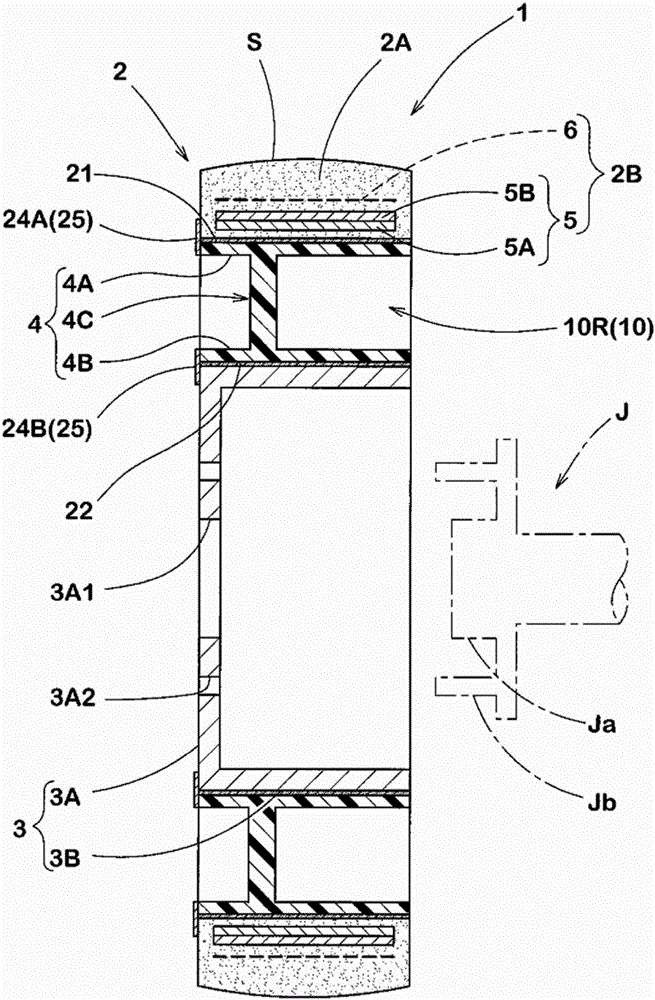

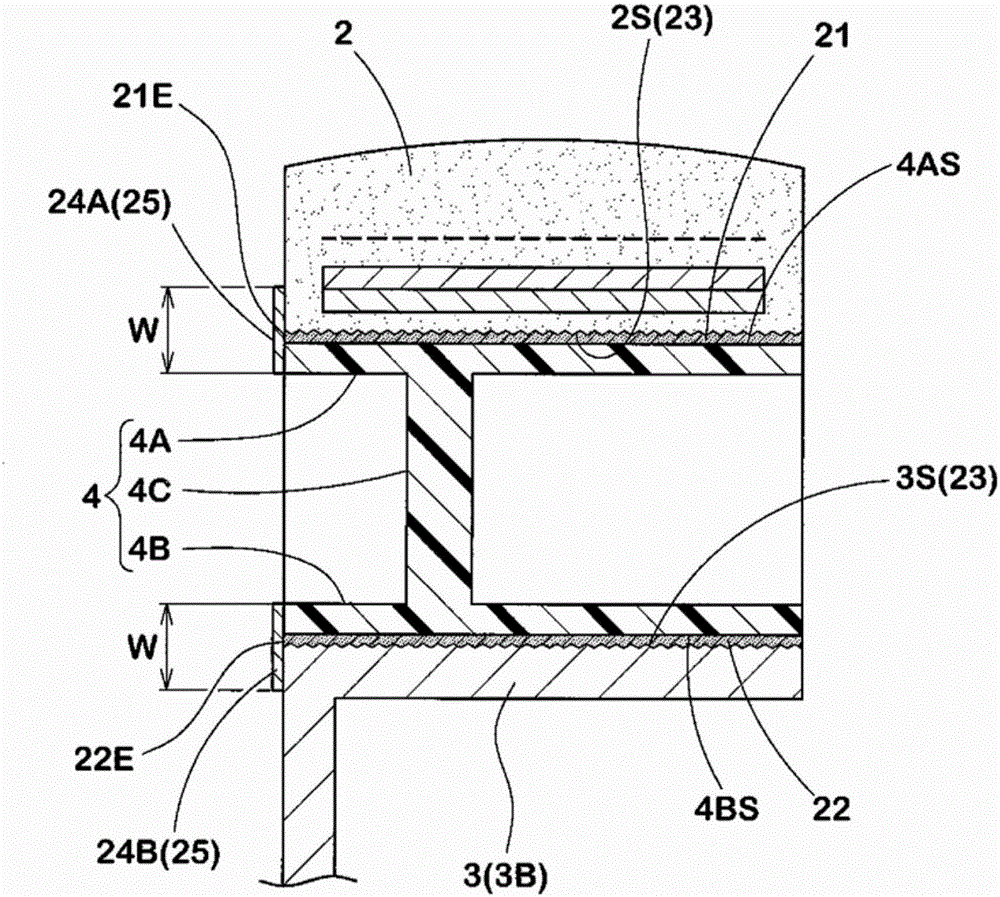

[0029] Such as figure 1 and figure 2 As shown in , the non-pneumatic tire 1 according to the first invention includes a cylindrical tread ring 2 having a contact area S, a hub 3 and spokes 4, and the hub 3 is arranged on the diameter of the tread ring 2. On the inside and fixed to the axle J, and the spokes 4 connect the tread ring 2 with the hub 3 . This embodiment shows a case where a non-pneumatic tire is formed as a tire for a passenger vehicle.

[0030] The tread ring 2 is a portion corresponding to a tread portion of a pneumatic tire and includes a tread rubber portion 2A and a reinforcing cord layer 2B embedded in the tread rubber portion 2A.

[0031] For the tread rubber portion 2A, it is preferable to employ a rubber composition excellent in frictional force to ground contact and wear resistance. And in order to impart wet performance, on the contact area S forming the outer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com