Glass panel for a space aircraft

A technology for aircraft and glass, which is applied to aircraft, spaceflight vehicles, spaceflight equipment, etc., and can solve problems such as limited certification standards or guidelines for space vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

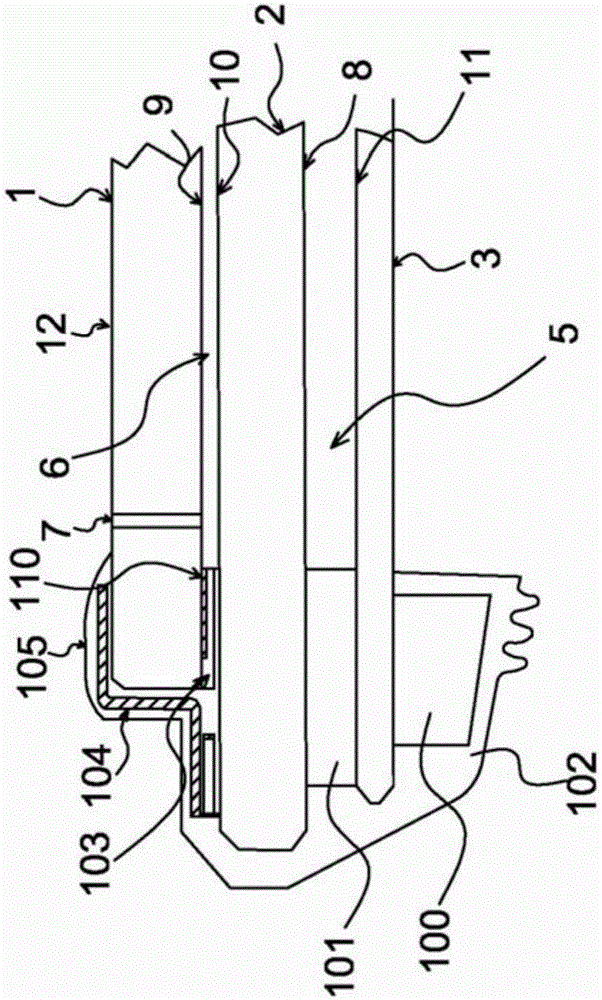

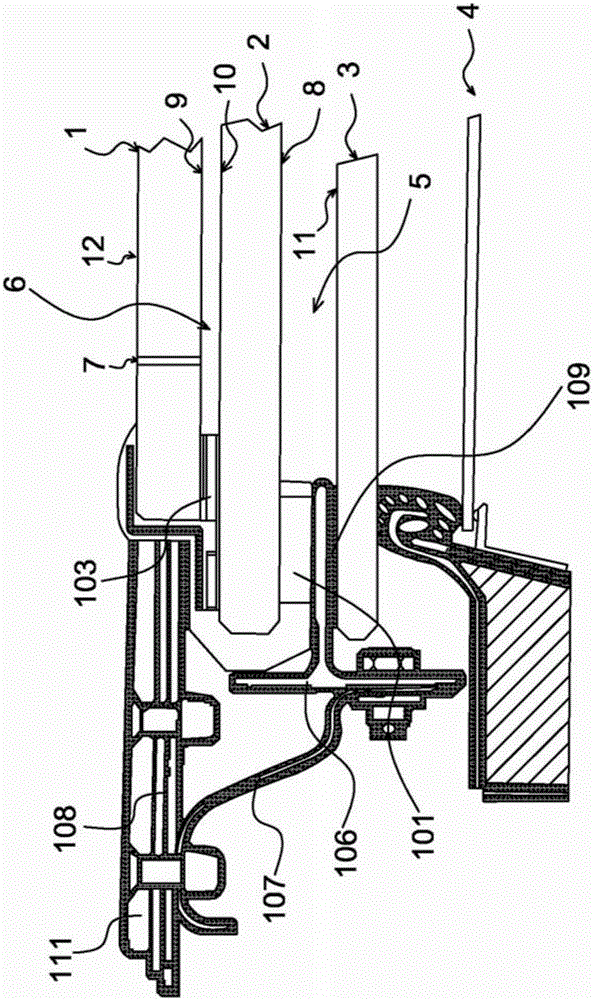

[0059] exist figure 1 The invention is described within the context of glazing assembled on a frame of known type adapted to be fixed by clamping, said frame comprising spacers 100, 101, 103, wherein the spacers 101, 103 define glass panels, The space 5 , 6 between the watertight seal 105 and the Z-shaped retaining plate 104 .

[0060] According to the invention, this glazing comprises an outer panel 1 , also called an outer panel, which must first of all be able to withstand impact stresses and thermal insulation during re-entry into the atmosphere.

[0061] Shock refers to shocks that occur in the field of aviation, and refers in particular to bird strikes, but also to shocks that may be caused by objects such as space debris during suborbital flight phases.

[0062] Unlike atmospheric aircraft, passenger windows must be designed to be highly resistant, or even as resistant as windshield glass, because high-velocity space debris may strike the aircraft at any angle.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com