Component mounting device and method of calibration in component mounting device

A technology of installation device and installation position, which is applied in the direction of electrical components, electrical components, etc., can solve the problems of high cost of component installation devices, poor image recognition, etc., and achieve the effect of reducing the number and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

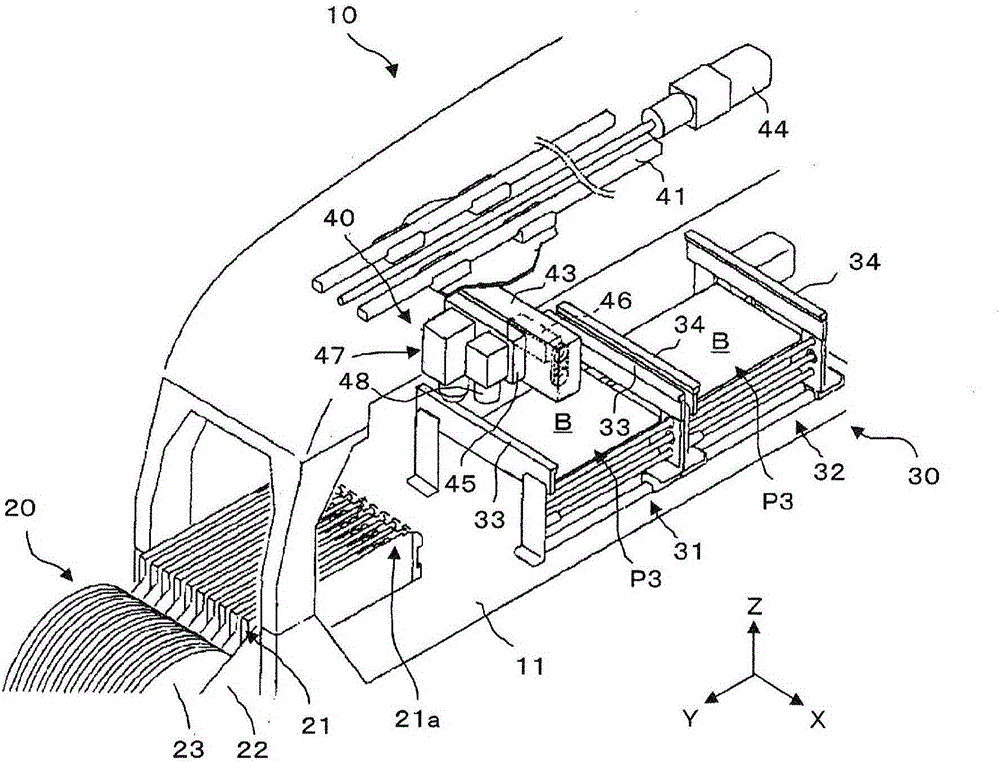

[0036] Embodiments of the present invention will be described below based on the drawings. like figure 1 As shown, the component mounting apparatus 10 includes a component supply unit 20 , a board transport unit 30 , and a component transfer unit 40 .

[0037]The components supply part 20 is comprised by the structure which arrange|positioned the some tape feeder 21 in parallel along the X-axis direction on the base 11 as an example. The tape feeder 21 is detachably attached to the main body frame 22 detachably attached to the base 11, and has a supply tape reel 23 which is wound and accommodated in a row at intervals. A strip of multiple electronic components. Although not shown in the figure, a motor serving as a driving source for pitch feeding the tape is built in the inside of the tape feeder 21, and the tape is fed out one pitch at a time by this motor, and the electronic components accommodated in the tape are sequentially supplied. It reaches the component supply po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com