Ramie wool warm socks and weaving method thereof

A hemp wool and sock body technology is applied in the field of hemp wool thermal socks and its weaving, which can solve the problems of poor wear resistance, roughness, and different thicknesses, and achieve the effects of good heat retention, dry inner layer and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the technical solution of the present invention, the present invention will be further described by the following examples.

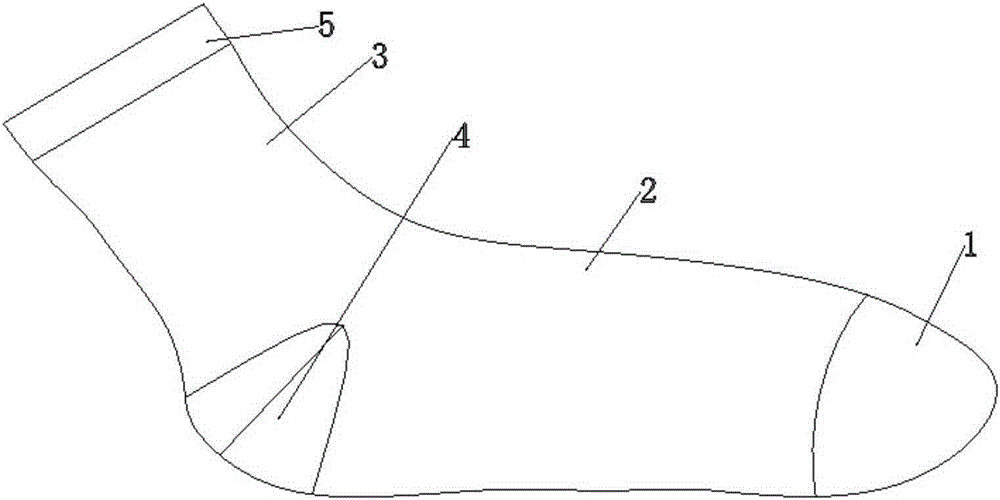

[0015] The hemp wool thermal socks (sock body) of the present embodiment is made of corresponding ramie yarn, free wool yarn and spandex elastic covering yarn, or is made of ramie yarn, free wool yarn, spandex elastic covering yarn, Woven from a blend of cotton and linen yarns and nylon yarns. Such as figure 1 As shown, its sock body includes a sock sole cover 2, a sock tube cover 3, a sock toe 1, a sock heel 4, and a sock opening 5 connected to the upper end of the sock tube cover. The sole cover and tube cover include a layer of rabbit wool yarn, a layer of ramie yarn or a layer of mixed cotton and linen yarn, and a layer of spandex elastic covering yarn. A layer of ramie yarn or a cotton-linen blend yarn layer is on the inner layer, and a rabbit wool yarn layer is on the outer layer. The toe and heel consist o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com