Manual microwave-absorbing coating application forming device and coating preparation method

A wave-absorbing coating and coating technology, which is applied in the interdisciplinary field of mechanical processing and material science, can solve the problems of inability to achieve accurate control of coating thickness, coating quality cannot be effectively guaranteed, and cost increases, so as to achieve guaranteed coating The effect of layer surface quality, strong equipment adaptability, and small footprint of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

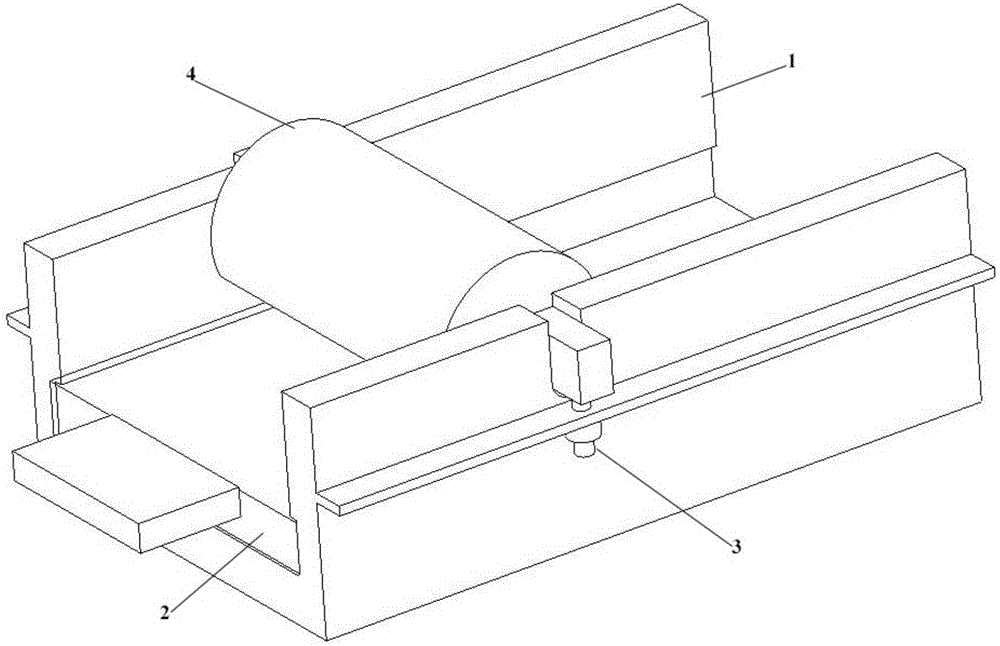

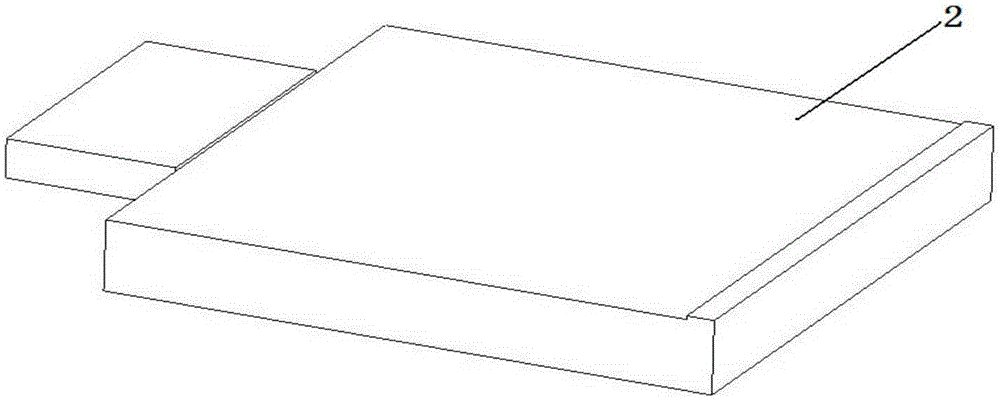

[0039] see Figure 1~4 , The coating coating device of the present invention includes a base 1, a push block 2, and a control module, wherein the control module is composed of a height support device and a coating mold 4. The height supporting device is a differential head 3.

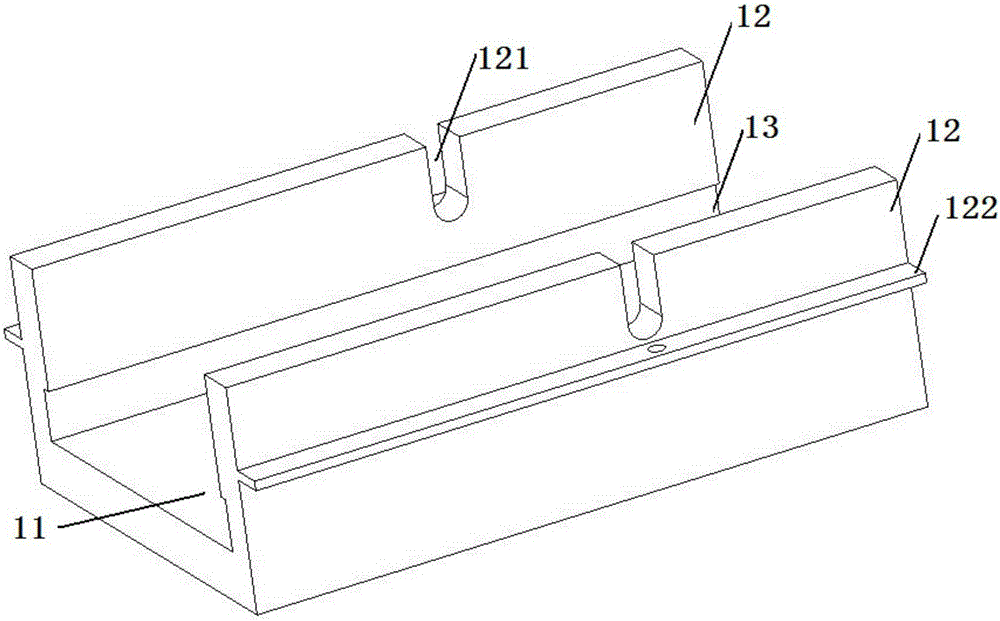

[0040] The base is mainly used for supporting and stabilizing, including the base bottom 11 and two support plates 12 parallel to each other, the lower ends of the support plates 12 are recessed inwardly, forming an inner groove 13 with the bottom of the base;

[0041] The relative position of the support plate 12 is provided with a bayonet 121;

[0042] A fixing strip 122 is provided on the outside of the support plate 12 below the bayonet 121;

[0043] The inner groove 13 is used for the adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com