General detection sieve

A technology of sieve cylinder and sieve mesh, applied in the field of general inspection sieve, can solve the problems of single function, fixed sieve mesh size, troublesome and other problems, and achieve the effect of stable and reliable work, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

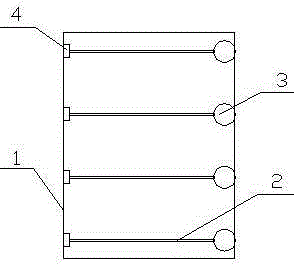

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention, a universal inspection sieve, including a sieve cylinder 1 and a sieve 2 arranged inside the sieve cylinder 1, an automatic winding roller 3 is evenly distributed on one side of the sieve cylinder 1, and the other side of the sieve cylinder 1 corresponds to an automatic The winding roller 3 is provided with a fastener 4, and the screen 2 is wound on the automatic winding roller 3. Pull out the screen 2 on the corresponding automatic winding roller 3 and fix it on the fastener 4 on the other side according to the requirements of use for inspection, which is convenient and quick.

[0010] The above description is only illustrative but not restrictive to the present invention. Those of ordinary skill in the art understand that many modifications, changes, etc. can be made without departing from the spirit and scope defined by the appended claims. Effective, but all fall within the protectio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap