Method for manufacturing suspending type mold photosensitive pattern

A manufacturing method and mold technology, which is applied in the field of manufacturing photosensitive patterns of suspended molds, can solve the problems of affecting product effects, incomplete patterns, cumbersome operations, etc., and achieve the effects of saving labor costs, clear patterns and simple operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can be further understood through the examples of the present invention given below, but the protection of the present invention is not limited thereto.

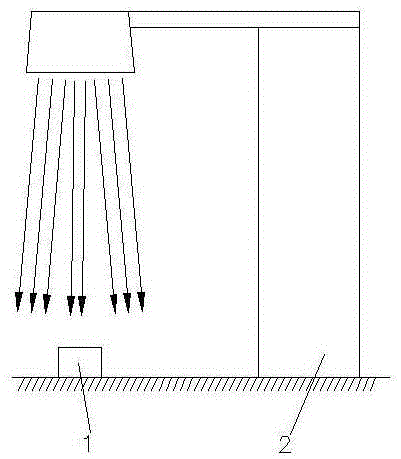

[0015] refer to figure 1 Shown, the manufacturing method of suspended type mold photosensitive pattern comprises the steps:

[0016] (1) Prepare the mold 1, the film plate with the pattern and the raw materials of the photosensitive anti-corrosion ink;

[0017] (2) Spray the photosensitive anti-corrosion ink evenly on the surface layer of the mold;

[0018] (3) Then fix the four sides of the film plate with the pattern on the surface of the mold. The film plate is in a suspended state on the surface of the mold and does not need to be completely attached

[0019] (4) Move the mold under the lampshade of the printing machine, and adjust the height according to the thickness of the pattern. Then start the printing machine to work, cure the photosensitive ink on the surface of the mold through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com