Blister tray

A tray and storage tank technology, applied in rigid containers, containers, packaging, etc., can solve the problems of waste of plastic tray utilization and inability to share, and achieve the effects of reducing management costs, enhancing commonality, and reducing types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

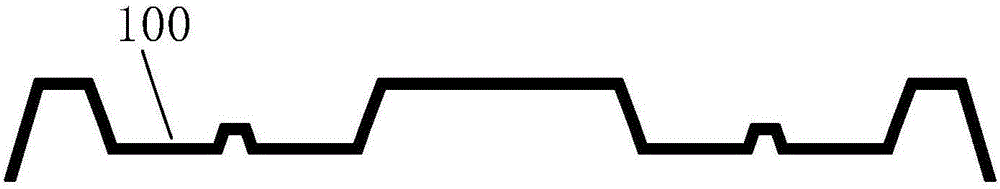

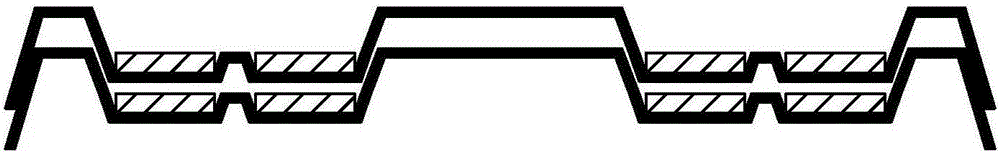

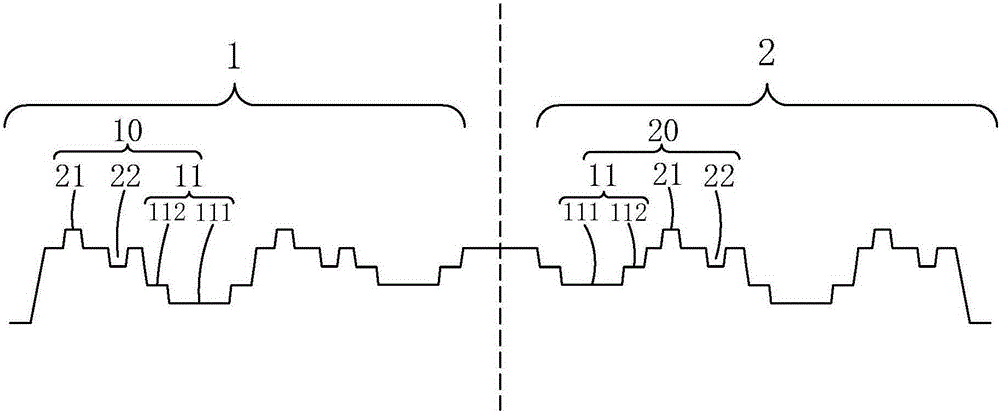

[0028] see Figure 3 to Figure 6 , the present invention provides a blister tray, including a first carrying unit 1 and a second carrying unit 2 respectively located on both sides of the centerline; the first carrying unit 1 includes several first structural units 10 arranged in a matrix, The first structural unit 10 includes a raised portion 21, a recessed portion 22, and an accommodating portion 11 arranged in sequence from left to right; the second carrying unit 2 includes several second structural units 20 arranged in a matrix, The second structural unit 20 includes an accommodating portion 11, a raised portion 21, and a recessed portion 22 arranged in sequence from left to right; the accommodating portion 11 is in a stepped shape and at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com