Lightweight loading and unloading machine

A loading and unloading machine, a portable technology, applied in hoisting devices, transportation and packaging, and clockwork mechanisms, etc., can solve problems such as large economic losses, claim disputes, high physical labor intensity, and low work efficiency, and reduce auxiliary time , reduce work intensity and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

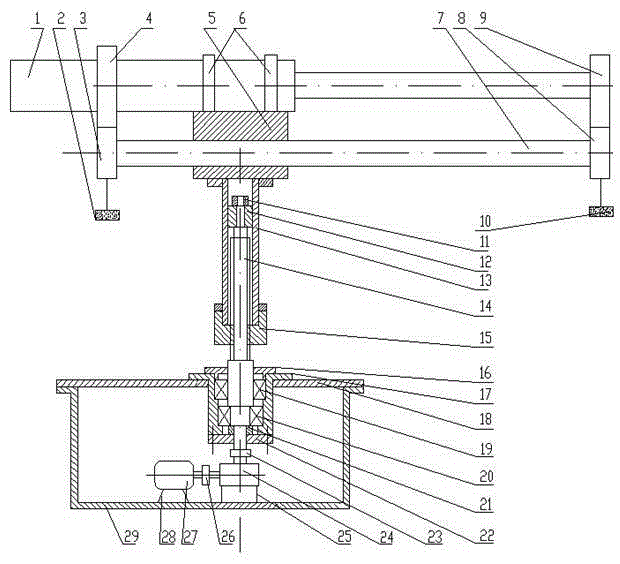

[0025] as attached figure 1 Shown, four sides and the bottom surface of box body 29 of the present invention are to be made with the metal material that has certain strength and rigidity, open above, and the interior leaves certain space, and worm gear reducer support frame 25 and motor support frame 28 They are respectively installed on the bottom surface; the box cover 18 is made of a metal material with certain strength and rigidity, and there is a through hole in the middle, covering the top of the box 29; the bearing seat 17 is installed in the through hole of the box cover 18 Among them, the radial bearing 19 and the thrust bearing 20 are installed inside; the upper cover plate 16 of the bearing seat is made of a metal material with certain strength and rigidity, and there is a round hole in the middle, which is installed on the top of the bearing seat 17; the column 14 is a step The shaft structure has threads and is made of metal material with certain strength and rigi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com