Cutting device of horizontal fabric cutting machine

A cloth cutting machine and cutting technology, applied in the cutting of textile materials, textiles and paper making, etc., can solve the problems of hot and hot cutting knives, affecting the cutting of cloth, reducing cutting efficiency, etc., to avoid cloth sticking, Good cooling effect, improving cutting efficiency and cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

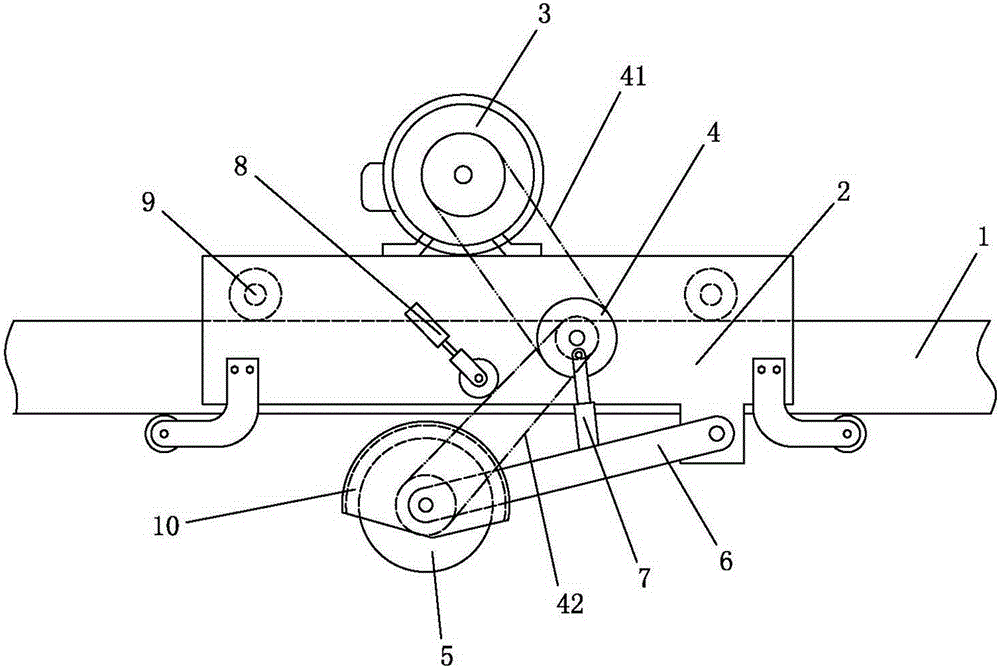

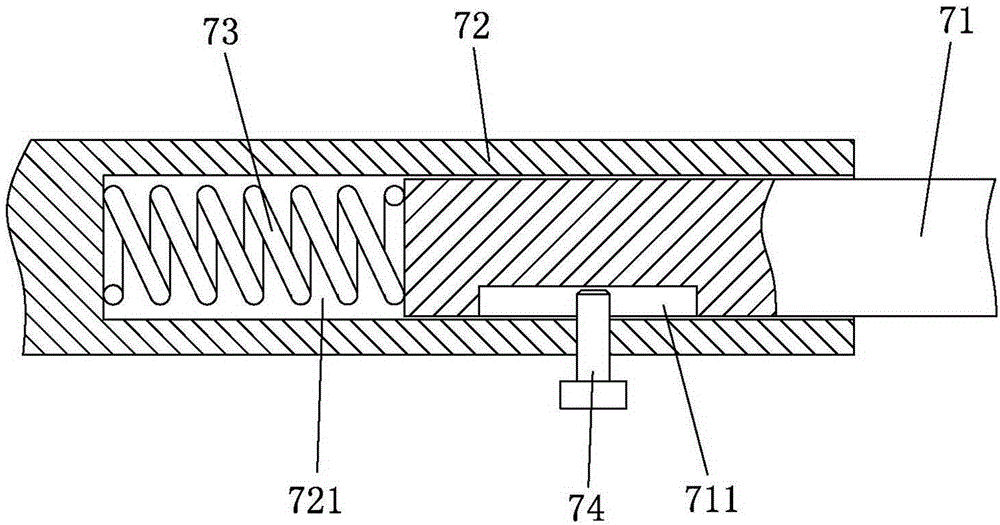

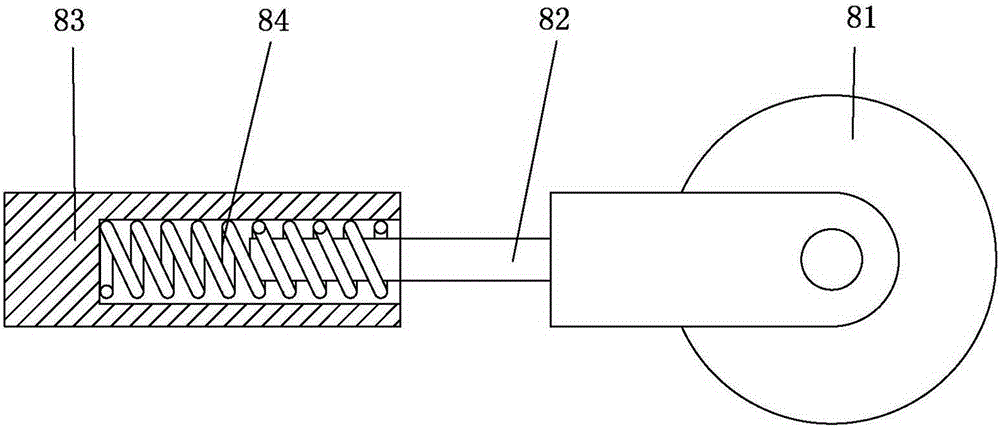

[0020] Example: such as figure 1 As shown, a horizontal cloth cutting machine includes a guide rail 1, a machine base 2, a motor 3, a transmission wheel 4, a disc blade 5 and a protective cover 10 arranged on the disc blade 5. The base 2 moves horizontally along the guide rail 1, and the base 2 is provided with guide wheels 9 sliding on the guide rail 1. The guide wheels 9 are distributed up and down, and conflict with the upper plane and the lower plane of the guide rail 1 respectively. The motor 3 is installed on the support 2, and the transmission wheel 4 is rotated and arranged on the support 2. The motor 3 drives the transmission wheel 4 to rotate, and the transmission wheel 4 drives the disc blade 5 to rotate. The disc blade 5 is installed on the swing mechanism, and the swing mechanism drives the disc blade to swing periodically up and down. The swing mechanism comprises a swing frame, on which three hinged ends distributed in a triangle are arranged, and the three hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com