Fireproof heat retaining panel used for manufacturing container house

A technology of fireproof insulation board and container house, which is applied in the direction of heat preservation, fire protection, building components, etc., can solve the problems of poor heat insulation performance, complicated manufacturing process, low living comfort, etc., to reduce production size, reduce cost, increase The effect of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

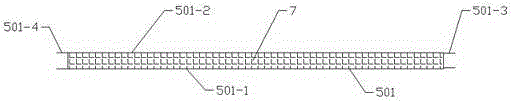

[0022] Please refer to the accompanying drawings, the fire insulation board 501 used to manufacture the container house adopted in the present invention is as figure 1 As shown, there is a certain gap between the inner layer board 501-1 and the outer layer board 501-2, and the inner layer board 501-1, and the gap is filled with rock wool 7, and the rock wool can also use other fireproof and thermal insulation materials to replace. Both ends of a fire-proof insulation board 501 are provided with a male groove 501-3 and a female groove 501-4 that are compatible with each other in size. Both the male groove 501-3 and the female groove 501-4 are U-shaped, and they are respectively connected to the inner layer The bottoms of the board 501-1 and the outer layer board 501-2, the male groove 501-3 and the female groove 501-4 respectively seal the rock wool on both sides of the fireproof insulation board. The internal width of the female groove 501-4 is slightly smaller than or equal ...

Embodiment 2

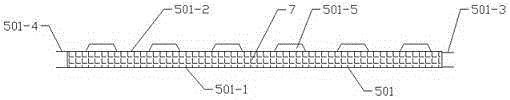

[0025] As an improvement of Embodiment 1, there are also square corrugations on the outer plate 501-2, but the rock wool does not fill into the corrugated area on the outer plate 501-2 that is convex (the side away from the inner plate is the outside) In this way, there is a cavity 501-5 in the protruding corrugated area on the outer layer plate 501-2, so that when the rock wool 7 expands after absorbing water, the protruding corrugated area forms a certain expansion space, avoiding the rock wool 7 The fireproof insulation board 501 caused by water absorption is bulged and deformed under the action of expanded rock wool. The remaining technical features in this example are the same as those in Embodiment 1.

[0026] The fireproof insulation board 501 can be used as the wall of the container house. When in use, the side of the outer corrugated board 501-2 with convex corrugations should face outside the wall, because the corrugations on the outer board of the fireproof insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com