Fireproof thermal-insulation material, and preparation method thereof

A technology of fireproof and heat preservation and raw materials, applied in the field of heat preservation materials, can solve the problems of aging performance, poor hydrophilic compressive and flexural strength properties, etc. The effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

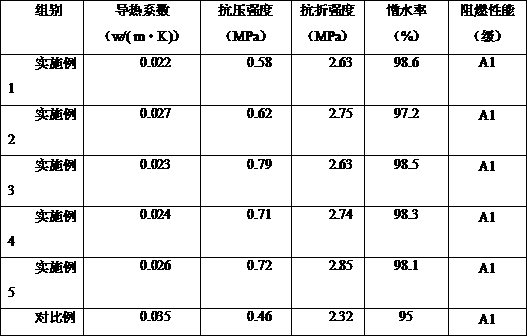

Examples

Embodiment 1

[0037] This embodiment relates to a fireproof and thermal insulation material, which includes the following raw materials in parts by weight: 20 parts of vitrified microspheres, 25 parts of modified sepiolite, 15 parts of attapulgite, 7 parts of ore fiber, 6 parts of glass fiber, phenolic resin 9 parts, 6 parts of fumed silica gel, 4 parts of zinc oxide, 3 parts of sodium carboxymethyl cellulose, 1 part of polyvinyl alcohol, 2 parts of honey, 3 parts of foaming agent, 2 parts of flame retardant, hydrophobic 2 doses,

[0038] The preparation method of described modified sepiolite is as follows:

[0039] a: Mix cornstarch, water, acrylic acid and dodecanethiol, then heat to 75°C for gelatinization to obtain a gelatinized product;

[0040] b: Preheat and dry the sepiolite powder in a drying oven at 100°C for 2 hours, add 25% ammonia solution accounting for 10% by mass of the sepiolite powder, stir at 50°C for 2 hours, filter the sepiolite powder, and dry ;

[0041] c: Then add...

Embodiment 2

[0054] This embodiment relates to a fireproof and thermal insulation material, which includes the following raw materials in parts by weight: 30 parts of vitrified microspheres, 35 parts of modified sepiolite, 30 parts of attapulgite, 14 parts of ore fiber, 13 parts of glass fiber, phenolic resin 18 parts, 11 parts of fumed silica gel, 8 parts of zinc oxide, 5 parts of sodium carboxymethyl cellulose, 2 parts of polyvinyl alcohol, 5 parts of honey, 4 parts of foaming agent, 5 parts of flame retardant, hydrophobic 3 doses,

[0055] The preparation method of described modified sepiolite is as follows:

[0056] a: Mix cornstarch, water, acrylic acid and dodecanethiol, then heat to 85°C for gelatinization to obtain a gelatinized product;

[0057] b: Preheat and dry the sepiolite powder in a drying oven at 120°C for 3 hours, add 25% ammonia solution accounting for 10% by mass of the sepiolite powder, stir at 60°C for 3 hours, filter the sepiolite powder, and dry ;

[0058] c: The...

Embodiment 3

[0071] This embodiment relates to a fireproof and thermal insulation material, which includes the following raw materials in parts by weight: 23 parts of vitrified microspheres, 29 parts of modified sepiolite, 20 parts of attapulgite, 8 parts of ore fiber, 9 parts of glass fiber, phenolic resin 10 parts, 7 parts of fumed silica gel, 5 parts of zinc oxide, 3.6 parts of sodium carboxymethyl cellulose, 1.3 parts of polyvinyl alcohol, 3 parts of honey, 3.2 parts of foaming agent, 3 parts of flame retardant, hydrophobic 2.2 parts of agent,

[0072] The preparation method of described modified sepiolite is as follows:

[0073] a: mixing cornstarch, water, acrylic acid and dodecanethiol, and then heating to 80°C for gelatinization to obtain a gelatinized product;

[0074] b: Preheat and dry the sepiolite powder in a drying oven at 110°C for 2.5 hours, add 25% ammonia solution accounting for 10% by mass of the sepiolite powder, stir at 55°C for 2.5 hours, filter the sepiolite powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com