Frame combining structure and corner combining method of wooden door and window sash

A technology for wooden doors, windows and door frames, applied in wing sash frames, window/door frames, windows/doors, etc., can solve the problems of high cost investment, difficulty in reaching groove and tenon corners, mold and other problems, so as to improve production efficiency and increase Convenience, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

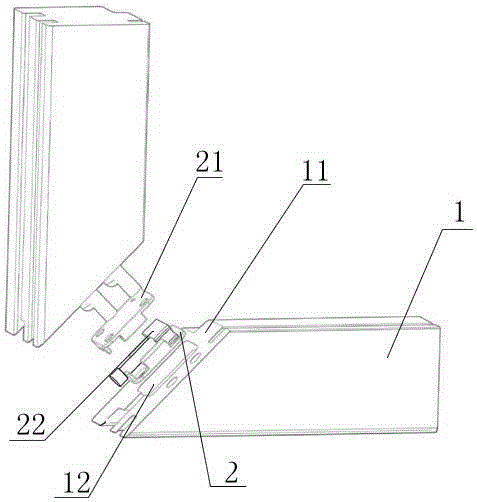

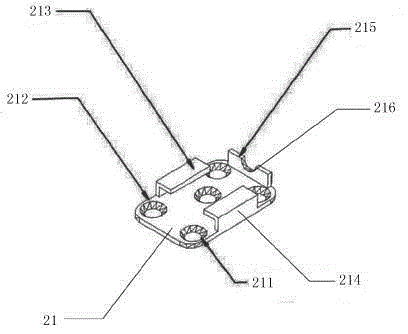

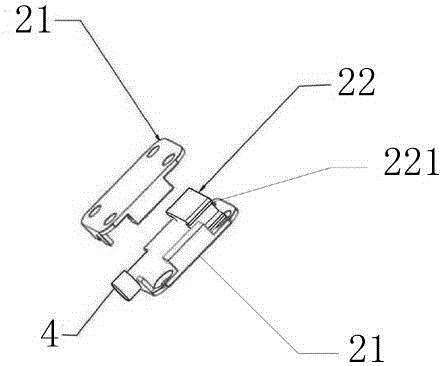

[0019] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, in the frame structure of a wooden door and window according to the present invention, the door and window at least includes a door and window frame or a door and window sash frame, and the described door and window frame or door and window sash frame is mainly composed of adjacent profile frame strips 1 through relative The corner joints 2 on the adjacent end faces are connected, and the connecting end faces of the two adjacent profile frame strips 1 are respectively made into a 0~180° section 11, and at least processing on the 0~180° section 11 There is a corner set positioning notch 12, and after the adjacent profile frame strips 1 are spliced with each other, a space is formed at the joint to accommodate the assembled corner set, and half of the corner set 21 is embedded and fixed in a profile frame In the positioning notch 12 on the 0~180° section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com